Darrieus Rotor

According to Wikipedia (https://en. wikipedia. org/w/index. php? title=Darrieus_wind _turbine&oldid=581321514):

“The Darrieus wind turbine is a type of vertical axis wind turbine (VAWT) used to generate electricity from the energy carried in the wind. The turbine consists of a

|

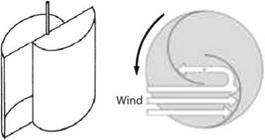

Fig. 10.3 Schematic drawings and operation of a two-scoop Savonius turbine, (from http://commons. wikimedia. org/wiki/File:Savonius_turbine. svg Author: Jaganath, http://commons. wikimedia. org/wiki/File:Savonius_Querschnitt. png Author Schargel) |

number of aerofoils vertically mounted on a rotating shaft or framework. This design of wind turbine was patented by Georges Jean Marie Darrieus, a French aeronautical engineer in 1931.

The Darrieus type is theoretically just as efficient as the propeller type if wind speed is constant, but in practice this efficiency is rarely realized due to the physical stresses and limitations imposed by a practical design and wind speed variation. There are also major difficulties in protecting the Darrieus turbine from extreme wind conditions and in making it self-starting.

In the original versions of the Darrieus design, the aerofoils are arranged so that they are symmetrical and have zero rigging angle, that is, the angle that the aerofoils are set relative to the structure on which they are mounted. This arrangement is equally effective no matter which direction the wind is blowing—in contrast to the conventional type, which must be rotated to face into the wind.

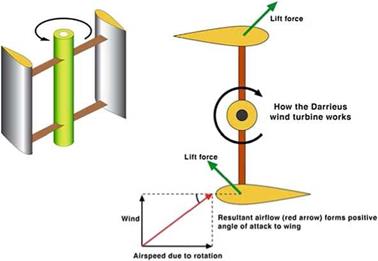

When the Darrieus rotor is spinning, the aerofoils are moving forward through the air in a circular path. Relative to the blade, this oncoming airflow is added vectorially to the wind, so that the resultant airflow creates a varying small positive angle of attack (AoA) to the blade. This generates a net force pointing obliquely forwards along a certain ‘line-of-action’. This force can be projected inwards past the turbine axis at a certain distance, giving a positive torque to the shaft, thus helping it to rotate in the direction it is already travelling in. The aerodynamic principles which rotates the rotor are equivalent to that in autogiros, and normal helicopters in autorotation.

As the aerofoil moves around the back of the apparatus, the angle of attack changes to the opposite sign, but the generated force is still obliquely in the direction of rotation, because the wings are symmetrical and the rigging angle is zero. The rotor spins at a rate unrelated to the windspeed, and usually many times faster. The energy arising from the torque and speed may be extracted and converted into useful power by using an electrical generator.

The aeronautical terms lift and drag are, strictly speaking, forces across and along the approaching net relative airflow respectively, so they are not useful here. We really want to know the tangential force pulling the blade around, and the radial force acting against the bearings.

|

Fig. 10.4 Schematic of a Darrieus turbine: perspective (left); top view (right) (from https://en. wikipedia. org/wiki/File:Darrieus. jpg Author: Grahamuk) |

When the rotor is stationary, no net rotational force arises, even if the wind speed rises quite high—the rotor must already be spinning to generate torque. Thus the design is not normally self starting. It should be noted though, that under extremely rare conditions, Darrieus rotors can self-start, so some form of brake is required to hold it when stopped. See. Fig. 10.4.

One problem with the design is that the angle of attack changes as the turbine spins, so each blade generates its maximum torque at two points on its cycle (front and back of the turbine). This leads to a sinusoidal (pulsing) power cycle that complicates design. In particular, almost all Darrieus turbines have resonant modes where, at a particular rotational speed, the pulsing is at a natural frequency of the blades that can cause them to (eventually) break. For this reason, most Darrieus turbines have mechanical brakes or other speed control devices to keep the turbine from spinning at these speeds for any lengthy period of time…

…In overall comparison, while there are some advantages in Darrieus design there are many more disadvantages, especially with bigger machines in MW class. The Darrieus design uses much more expensive material in blades while most of the blade is too near of ground to give any real power. Traditional designs assume that wing tip is at least 40 m from ground at lowest point to maximize energy production and life time. So far there is no known material (not even carbon fiber) which can meet cyclic load requirements”.

|

Fig. 10.5 NREL turbine in NASA Ames 80′ x 120′ wind tunnel, from Ref [1] |