Take-Off and Landing

No aircraft can fly without take-off and landing Therefore low-speed performance is crucial for the aircraft’s viability. Low speed performance determines the required thrust dunng take-off and landing, and so strongly influences airport noise. For future SCT. take off noise is the most difficult requirement! And a viable SCT must be even quieter than what is required today by certification authorities (stage 3). since many airports do not accept noisy climbing aircraft which

comply to stage 3. They have to respect the concerns of the sourrounding communities and have to restrict noisy aircraft in order to maintain their airport certification

At low speeds, high lift or high angles of attack arc required. Wave drag docs not exist, friction drag is nearly constant, so induced drag (and separation drag) dominates. This leaves only the last term in eqs. (49) or (50).

CD = AT, SCj/(Kfe:) (57)

or in physical units

D = KrW2/(nqb2) (58)

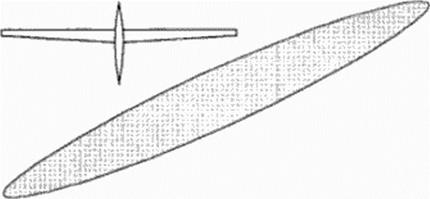

To minimize induced drag, we need a large span. This can be seen at high performance low speed planes like gliders, sec Figure 18. Sweep does ти help for drag, but special configurations (like the OFW) need it for stability and control For SCTs. the variable geometry of the OFW helps for take-off drag minimization. But it also reduces drag at low landing speeds; therefore an OFW needs additional pitching moment free devices to produce drag for landing. •

|

Figure 18 Low Speed Planes Additionally we must avoid separation: |

itself. This reduced lifting span increases drastically the induced drag. Figure 19. And Concorde needs its noisy afterburners to overcome this drag dunng take off.

• A new SCT has to avoid leading edge separation dunng climb to enable low noise proce durcs.

b: span for linear (potential) lift

b: span for linear (potential) lift

byispan for additional vortex lift

|

by

b

Figure 20 shows a design exercise for a new "Concordc-likc" SCT (for 250 passengers. 5 (XX) nm): Reference is a DA-dcsign (DA: Daimler-Benz Aerospace Airbus» of an aircraft which is optinu/ed just to meet stage 3. But because noise prediction is not very precise, the influence of aircraft noise on aircraft weight (MTOW) was investigated. Each square represents an optimized aircraft producing either more calculated noise than stage 3 (+ 0.5. to +9 dB) or less calculated noise (-0.5 dB) Weight strongly increases for lower noise, and just for – I dB no solution was found. It has to be respected, that noise measurement at certification has a scatter of nearly 2 dB. calculated noise prediction about 3 dB and weight prediction has its scatter also. This means that our design is still more than marginal!