Impingement Jet

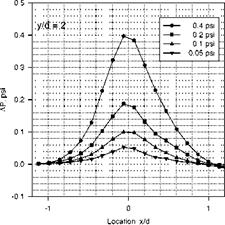

Torgerson et al. (1996) conducted PSP experiments in a low-speed impinging jet to determine the limiting pressure difference that can be resolved using a laser scanning system combining an optical chopper or acoustic-optic modulator with a lock-in amplifier. They tested three PSP formulations, Ru(dpp) in GE RTV 118, PtTFPP in model airplane dope and PtTFPP/Green-Gold in dope. Ru(dpp) in GE RTV 118 had a relatively low temperature sensitivity of 0.78%/°C compared to 1.8%/°C for PtTFPP-dope PSP. PtTFPP/Green Gold in dope was a two – luminophore PSP where Green Gold served as a pressure-insensitive reference dye. They compared the intensity ratio method, phase method and two-color ratio method to evaluate their feasibility for low-speed PSP measurements. The paint was coated on a white Mylar film attached on an aluminum impingement surface that was located at 10 mm away from a 5-mm diameter nozzle. A laser beam modulated by an optical chopper provided illumination for PSP at 457 nm. A 0.2mm laser spot was scanned across the impingement plate. The luminescent emission was detected using a PMT through a long-pass filter (>600 nm). The PMT signal was input into a lock-in amplifier connected with a PC either to reduce the noise for intensity-based measurements or to extract the phase angle for phase-based measurements. For Ru(dpp) in GE RTV 118, a typical chopping frequency was 500 Hz with a lock-in time constant set to 200 ms. Pressure was calculated from the intensity ratio and the phase angle after five scan ensembles were averaged. Figure 9.19 shows the pressure distributions on the impingement plate converted from the intensity ratio of Ru(dpp) in GE RTV 118, where the lateral coordinate is normalized by the nozzle diameter. These results indicated that the laser scanning system, working with Ru(dpp) in GE RTV 118, was able to measure an absolute pressure difference as low as 0.05 psi with a reasonable accuracy. However, it was found that the PtTFPP-dope PSP exhibited a stronger temperature effect distorting significantly the pressure distribution near the shear layer region of the impinging jet.

Phase measurements in the wind-off case for Ru(dpp) in GE RTV 118 and PtTFPP in dope led to a somewhat surprising finding that the phase angle showed a repeated variation or pattern over a scanning range even when pressure and temperature were uniformly constant. The phase variation introduced a considerable error in low-speed PSP measurements although it might not be significant for PSP application to high-speed flows. The phase variation was attributed to microheterogeneity of a polymer environment around a probe molecule that locally altered the luminescence and quenching behavior. To correct this intrinsic pattern of the phase angle (or lifetime), a ratioing process is still needed. Similarly, for the two-luminophore paint PtTFPP/Green-Gold in dope, a two-color intensity ratio was not constant over a scanning range because the two dyes were not homogeneously mixed into the binder. In this case, a ratio – of-ratios of the signals was used to remove this effect.

|

Fig. 9.19. Pressure distributions in a low-speed impinging jet obtained using a laser scanning system. From Torgerson et al. (1996) |