Synchronizing

One source of noise audible to the occupants of twin-engine aircraft occurs when the propellers are not synchronized. The noise can be heard as a throbbing sound when the props are ‘out of synch’ caused by a vibration due to the difference in RPM between each engine. When the props are correctly synchronized the noise becomes a steady hum. The vibratory frequency is only a discomfort to the occupants and does not in any way affect the structural integrity of the airframe.

The propellers can be synchronized in one of four different methods. The first two manual methods apply to light twin – engine aircraft, and the following two methods are applicable to larger more sophisticated aircraft. On a twin-engine aircraft with fixed-pitch props (not many around these days) the required RPM/power is set first with the throttles and then one throttle is slowly adjusted either way until the throbbing noise becomes a steady hum. With constant-speed props,

|

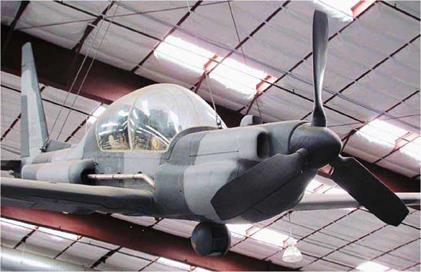

The North American B-25J Mitchell bomber has rounded

prop tips, typical of many aircraft until the 1960s

when square tips became common. Pima Air & Space

Museum, Tucson, Ar, is home to this aircraft.

the required manifold pressure is selected with the throttles followed by selecting the chosen RPM with the prop pitch levers in the usual manner. One prop lever is then adjusted either way to synchronize the props to a steady hum. Depending on the make of engine, some props are more easily synchronized by retarding the prop pitch lever, and on other engines the lever should be advanced. The throbbing beat will slow down and merge into a steady hum when the control is moved in the correct direction, while a quickening of the beat indicates the control is being moved the wrong way, so readjust accordingly.

Turboprop aircraft employ the use of a prop synchronizer. This is an electrical system comprising a generator mounted on each engine, with one engine (usually the right-hand engine) being the master unit. Signals from the left-hand engine’s generator are adjusted electrically to match those of the master unit, ensuring all propellers rotate at the same RPM

The fourth method uses a prop synchrophaser, developed by Hamilton Standard in 1978. The synchrophaser controls the engine RPM exactly by ensuring the prop blades on each engine pass through the same angular location at the same time. The prop’s RPM is fine-tuned electrically by the phase signals from each engine’s generator. When the props are turning with a phase difference of plus or minus one degree, a noise reduction of to 6.5 decibels (6.5 dB) is possible, while a phase difference of plus or minus five degrees produces a 4.5 dB reduction. Commuter and business aircraft usually employ the ± 5° phase due to the lower installation costs. A control is provided for the pilot to fine tune the system by altering the phase angle slightly in order to obtain the preferred sound level. The system can also be turned on or off as required, but must always be turned off for take-off and landing in case of engine failure. Decreasing engine RPM on the failed engine would cause the other engine to follow suit, if engaged.

How Noisy are They?

So far, only a brief reference has been made to the amount of noise produced by the props. So, how noisy are they? Answer – quite a lot, but to be more precise… the noise will be in the region of 76-80 dB during take-off for a high performance single-engine aircraft, decreasing to around 70 dB or even lower for an aircraft with a fixed-pitch propeller. Fixed-pitch props are generally quieter due to the prop’s relatively smaller diameter and lower RPM, which are the two main factors that influence the tip speed and prop noise. It follows, a fixed-pitch prop with a relatively short diameter does not attain full RPM during take-off and because its tip speed is typically around 600 feet per second at 2500 RPM, it will be relatively quiet. Conversely, a high-performance single with a constant-speed prop will attain maximum RPM (2700-2900) during take-off

|

A Lockheed YO-3 Quiet Star observation aircraft, with a three – blade, wide chord prop. This is one of the quietest planes built due to the very quiet propeller and other features. It is housed in the Pima Air & Space Museum, Tucson, Ar. |

and climb out, and will generate considerably more noise due to the greater RPM and higher tip speed. For any given aircraft, a three-blade prop will usually be of shorter radius than a two – blade propeller and three-blades are preferable because they generate more acceptable sound frequencies than two-blade props

The American FAA 36 noise regulations (1988) places a limit of 80 dB maximum for the certification of new aircraft types, but some older aircraft can easily exceed this figure. It is up to the individual pilot to operate his/her aircraft as quietly as possible to avoid undue noise to airport neighbors. A noise abatement departure can be achieved by reducing the RPM as soon as is safely convenient after take-off and then climbing at the maximum rate of climb to gain as much altitude as possible before reverting to the cruise/climb procedure. The intensity of the plane’s noise will decrease inversely with the square of the distance from the plane, altitude and distance are both excellent buffers of noise. However, what noise is sweeter than that of an aircraft taking-off and flying overhead? It sure beats ‘heavy metal’ rock music!