Boundary layer and stalling problems on swept wings

On a swept wing, the pressure gradients are such that they cause the boundary layer to thicken towards the wing tips. Thus, unless corrective measures are taken, the flow is likely to separate near the tips before any other part of the wing. This is in addition to the inherent tip-stall tendency of swept wings due to upwash, described in Chapter 2. For moderately swept wings at high angles of attack, the outboard stalling is exacerbated by the formation of leading-edge conical vortices which curve inwards, away from the tips, as shown in Fig. 2.20.

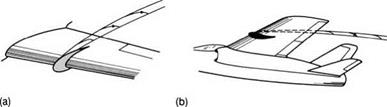

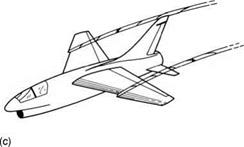

One way to alleviate the problem, is to fit chordwise fences on the wing, as shown in Fig. 3.8(a) and Fig. 3.9. Wing fences effectively split the wing into separate sections and help to prevent spanwise thickening of the boundary layer. At the fence, a trailing vortex is shed, rotating in the opposite sense to the usual wing-tip trailing vortex. The vortex produced by the fence scours away the boundary layer locally.

|

|

|

Fig. 3.8 Devices for inhibiting flow separation on swept wings (a) Wing fence (b) Vortilon (c) Saw-tooth leading edge |

|

Fig. 3.9 A wing fence on an early jet transport The fence helps to prevent the spanwise thickening of the boundary layer on a swept wing partly by inhibiting the spanwise flow, and partly by generating a vortex which draws in the slow-moving air of the boundary layer |

It was found that this trailing vortex also had the useful effect of stabilising the position of the leading-edge conical vortices which form at high angles of attack, thereby tending to improve the stability and control near the onset of stall.

The fence need not extend over the whole chord, and the short leading-edge fence shown in Fig. 3.9 and Fig. 3.8(a) was a device used on many early swept wing aircraft.

The vortilon shown in Figs 3.8(b) and 3.10 is a small fence-like surface extending in front of the wing and attached to the under-surface close to the stagnation line. It is intended to generate a vortex over the upper surface, but only at high angles of attack, when it is most needed. Engine mounting pylons can conveniently be used for the same purpose.

In the saw-tooth leading-edge design shown in Fig. 3.11, the abrupt change of chord causes a strong trailing vortex to form at this point. A trailing vortex is formed wherever there is an abrupt change of wing geometry.

On forward-swept wings, the boundary layer tends to thicken towards the inboard end, encouraging the centre section to stall first. Although this is a safer characteristic than tip-stall, it still produces a diverging nose-up pitching

|

Fig. 3.10 The vortilon is intended to generate a vortex at high angles of attack. The vortex inhibits the spanwise thickening of the boundary layer, and helps to stabilise the position of the separated leading-edge vortex |

|

Fig. 3.11 The saw-tooth leading edge also produces a vortex |

|

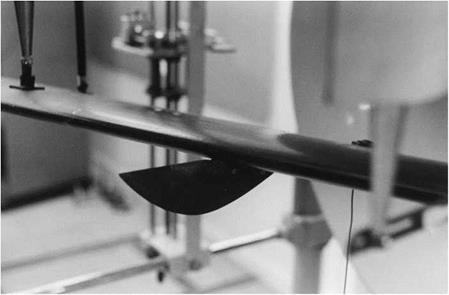

Fig. 3.12 Inboard strakes on this model of a forward-swept-wing aircraft help prevent flow separation at the wing root |

moment, and preventative measures are necessary. In the forward-swept model shown in Fig. 3.12, inboard strakes have been added so that the inboard section behaves like a slender delta, and does not stall in the conventional sense. The strong separated vortex also helps remove the thick boundary layer. On the forward-swept X-29 (Fig. 9.20) the downwash and trailing vortices produced by ‘canard’ foreplanes are used to inhibit inboard separation.