Boundary layer scale effect – model testing

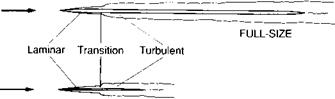

In Fig. 3.18 we show two thin almost flat wing sections, a full-size one and a scale model, placed at zero angle of attack in a stream of air. In this situation, the position of transition from laminar to turbulent flow will be roughly the same distance from the leading edge in both cases, as illustrated.

From the diagram, you will see that the scale model will therefore have a greater proportion of laminar boundary layer, and consequently a lower drag per unit of area than for the larger one. So the drag per unit area measured on the model is not representative of full scale.

To correct for the effect of scale, the model could be placed in a stream of air moving faster than that for the larger section. This would increase the Reynolds number, and move the position of transition forward. If the speed were sufficiently high, transition could be moved to a position corresponding to that of the full-scale section.

|

MODEL Fig. 3.18 On a thin flat plate at zero angle of attack, the transition position would be at roughly the same distance from the leading edge for both model and full-size plates. The model would therefore have a higher proportion of laminar boundary layer |

The same principle applies to all shapes, and to obtain similar flow patterns between model and full scale, it is necessary to ensure that the Reynolds number in the model test is the same as for the full-size aircraft in flight.

The Wright brothers and other early experimenters were either unaware of this fact, or did not bother about it. Their simple wind-tunnel tests conducted on very small models at low speeds indicated that thin plate-like wings gave a better ratio of lift to drag than ones with a thicker aerofoil type of section. Thus, early aircraft had thin plate-like wings. It was Prandtl who spotted the error, and found that when the Reynolds number of the tests was increased by running the tunnel faster, or using larger models, thicker wing sections produced a better lift-to-drag ratio than curved or flat plates.

The reason for the poor performance of thick aerofoil sections at very low Reynolds numbers (small models at low speeds), is that the flow will be laminar over most of the surface and thus will separate very easily. A thin plate with a sharp leading edge generates turbulence at the leading edge, and the resulting turbulent boundary layer is better able to stay attached. Model aircraft often perform better when equipped with means of turbulating the boundary layer, and require quite different wing section shapes from full-size aircraft, as described by Simons (1999).