Hydraulic Control Boost

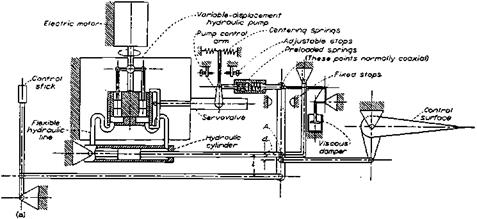

Control boost by hydraulic power refers to the arrangement that divides aerodynamic hinge moment in some proportion between the pilot and a hydraulic cylinder. A schematic for an NACA experimental boosted elevator for the Boeing B-29 airplane shows the simple manner in which control force is divided between the pilot and the hydraulic boost mechanism (Figure 5.16). Boosted controls were historically the first hydraulic power assistance application.

|

Figure 5.16 A very early hydraulic-boost control, installed by NACA for test on a Boeing B-29 elevator. Boost ratio l/d is varied by adjusting the location of point A. (From Mathews, Talmage, and Whitten, NACA Rept. 1076, 1952) |

By retaining some aerodynamic hinge moments for the pilot to work against two things are accomplished. First, the control feel of an unaugmented airplane is still there. The pilot can feel in the normal way the effects of high airspeeds and any buffet forces. Second, no artificial feel systems are needed, avoiding the weight and complexity of another flight subsystem. Hydraulic power boost came into the picture only at the very end of World War II, on the late version Lockheed P-38J Lightning, and only on that airplane’s ailerons. After that, hydraulic power boost was the favored control system arrangement for large and fast airplanes, such as the 70-ton Martin XPB2M-1 Mars flying boat, the Boeing 307 Stratoliner, and the Lockheed Constellation series transports, until irreversible power controls took their place.

5.13 Early Hydraulic Boost Problems

Early hydraulic boosted controls were notoriously unreliable, prone to leakage and outright failures. Among other innovative systems at the time, the Douglas DC-4E prototype airplane had hydraulic power boost. Experience with that system was bad enough to encourage Douglas engineers to face up to pure aerodynamic balance and linked tabs for the production versions of the airplane, the DC-4 or C-54 Skymaster.

A similar sequence took place at the Curtiss-Wright plant in St. Louis, where the Curtiss C-46 Commando was designed. At a gross weight of45,000 pounds, the C-46 exceeded O. R. Dunn’s rule of thumb of30,000 pounds for the maximum weight of a transport with leading – edge aerodynamic balance only. Thus, the CW-20, a C-46 prototype, was fitted initially with hydraulic boost having a 3:1 ratio, like those on the Douglas DC-4E Skymaster prototype and the Lockheed Constellation. However, maintenance and outright failure problems on the C-46’s hydraulic boost were so severe that the Air Materiel Command decreed that the airplane be redesigned to have aerodynamically balanced control surfaces. The previous successful use of aerodynamic balance on the 62,000-pound gross weight Douglas C-54 motivated the Air Corps decree. This was the start of the “C-46 Boost Elimination Program,” which kept one of this book’s authors (Larrabee) busy during World War II.

Another airplane with early hydraulically boosted controls was the Boeing 307 Strato- liner. Hydraulic servos were installed on both elevator and rudder controls. Partial jamming of an elevator servo occurred on a TWA Stratoliner. This was traced to deformation of the groove into which the piston’s O ring was seated. The airplane was landed safely.