Other methods of lift generation

Controlled separation – conical vortex lift

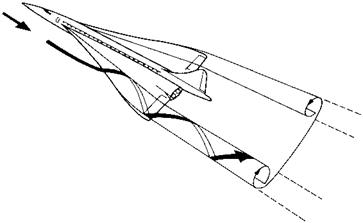

On aircraft with straight unswept wings, flow separation results in a poor ratio of lift to drag, and buffeting due to instability of the flow. However, if the wings are swept back at a sharp angle, the separated flow will roll up into a pair of stable cone-shaped vortices, as shown in Fig. 1.21. Unlike the bound vortex of a conventional wing, which merely represents a circulatory tendency, these are real vortices; swirling masses of air, as in a whirlwind.

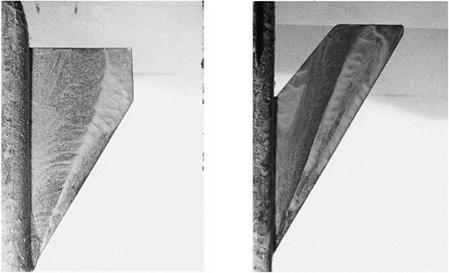

The presence of these leading-edge conical vortices is revealed in Fig. 1.20 by the vapour condensation clouds that they produce. Their influence is also evident in the surface flow patterns shown in Fig. 1.22.

This type of separated vortex flow represents an alternative method of lift generation. The air speed in the vortex is high, and so the pressure is low. Thus,

|

Fig. 1.20 Conical vortex lift The strong conical vortex that forms over the leading edge of a slender delta wing can sometimes be seen by the vapour condensation that it produces. Because of the high angle of attack required on landing and take-off, the nose of concorde had to be lowered to enable the pilot to see the runway (Photo courtesy of British Aerospace (Bristol)) |

lift is still produced by exposing the upper surface to a lower pressure than the underside, but the low pressure on the upper surface is now produced mainly as a consequence of the vortex motion above it.

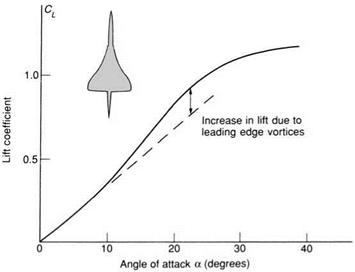

At low angles of attack, the flow on a slender delta or highly swept wing may remain attached, and lift can be generated in the conventional way. As separation takes place, and the vortices form, an extra contribution to lift occurs, as shown in Fig. 1.23. It will be seen that the CL to angle of attack curve is not a straight line.

The slender delta-winged Concorde was designed to fly with separated conical vortex flow in normal flight conditions. The leading edge is sharp to encourage leading edge separation at moderate angles of attack.

This conical vortex flow may be thought of as being a form of controlled separation. When lift is generated in this way, the wing will not stall in the conventional sense, and the lift will continue to increase for angles of attack up to 40 degrees or so. At higher angles, the vortices start to break down, and the lift falls off.

|

Fig. 1.21 Controlled separation on a slender delta The flow separates along the leading edges and rolls up into a pair of conical vortices. The low pressure in the vortices contributes to the production of lift |

|

Fig. 1.22 Surface flow patterns on a delta and a highly swept wing The model wings have been painted with a suspension of white powder (titanium dioxide) in paraffin. The scouring effect of the separated leading edge conical vortices can be seen |

|

Fig. 1.23 Variation of lift coefficient with angle of attack for a slender delta At high angles of attack, the leading edge vortices make a significant extra ‘non-linear’ contribution to lift |

Slender delta and highly swept wings have advantages in supersonic flight, as we shall describe in later chapters. This method of lift generation is, therefore, most frequently used on aircraft designed for supersonic flight. Separated vortex flow has, however, kept generations of paper darts flying across classrooms; a fact that demonstrates that this is also a suitable method of producing lift; even at low subsonic speeds.

Interestingly, a slender delta aircraft, based no doubt on the paper dart, was proposed in the nineteenth century; it was to be propelled by a steam jet!

Separated vortex lift is sometimes used in conjunction with conventional lifting surfaces to prevent stalling locally. A strake in front of a fin or tailplane helps to prevent stalling of these surfaces during manoeuvres especially at low speeds. A fin strake may be seen on the Dash-8, in Fig. 13.4. The design of wings for separated vortex flow is dealt with in more detail in the next chapter.