Skin Friction Drag

The friction between the surface of a body and the fluid causes viscous shear stress and this force is known as skin friction drag. Wall shear stress т at the surface of a body is given by:

where g is the dynamic viscosity coefficient and dVx/dy is the velocity gradient at body surface y = 0. If the velocity profile in the boundary layer is known, then the shear stress can be calculated.

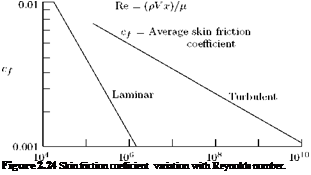

For streamlined bodies, the separated zone being small, a major portion of the drag is because of skin friction. We saw that bodies are classified as streamlined and bluff, based on which is dominant among the drag components. A body for which the skin friction drag is a major portion of the total drag is termed streamlined body. A body for which the pressure (form) drag is the major portion is termed bluff body. Turbulent boundary layer results in more skin friction than a laminar one. Examine the skin friction coefficient cf variation with Reynolds number, for a flat plate kept at zero angle of attack in a uniform stream, plotted in Figure 2.24. The characteristic length for Reynolds number is the plate length x, from its leading edge. It can be seen from Figure 2.24 that the Cf is more for a turbulent flow than laminar flow. The friction coefficient is defined as:

|

where V», p are the freestream velocity and density, respectively, and S is the wetted surface area of the flat plate.

For bluff bodies, the pressure drag is substantially greater than the skin friction drag, and for streamlined bodies the condition is the reverse. In the case of streamlined bodies, such as aerofoil, the designer aims at keeping the skin friction drag as low as possible. Maintaining laminar boundary layer conditions all along the surface is the most suitable arrangement to keep the skin friction low. Though such aerofoils, known as laminar aerofoils, have been designed, they have many limitations. Even a small surface roughness or disturbance can make the flow turbulent, and spoil the purpose of maintaining the laminar flow over the entire aerofoil. In addition, for laminar aerofoils there is a tendency for the flow to separate even at small angles of attack, which severely restricts the use of such aerofoils.