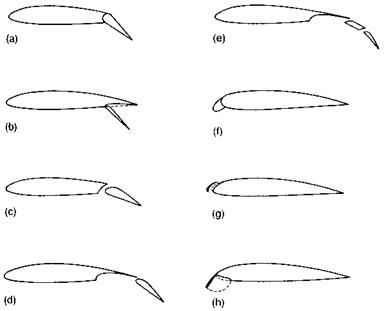

Trailing-edge flaps

In Chapter 1, we described how the lift coefficient of a wing depends on its camber. The wing camber can be changed in flight by deflecting the trailing edge downwards as shown in Fig. 3.13. The hinged trailing edge is known as a flap. The simple hinged flap shown in Fig. 3.13(a) is often used on light aircraft. The split flap shown in Fig. 3.13(b) is an alternative arrangement that was commonly used during and just after the Second World War.

The stalling effect, caused by flow separation, however, limits the maximum value of CL that can be obtained in this way. The key to producing very high

|

Fig. 3.13 Passive high lift devices The increase in CL depends on the precise geometry of the device and the wing section, but generally, the most complicated devices tend to be the most effective. Increases in CL (max) vary from about 50 per cent for the simple camber flap to more than 100 per cent multi-element devices (a) hinged or camber flap (b) split flap (c) slotted flap (d) slotted extending (e) double slotted extending flap (f) dropped leading edge (g) extending leading-edge slat (h) leading-edge or Kruger flap |

lift coefficients is to be found in inhibiting or controlling the separation of the boundary layer.

Since separation is associated with the dissipation of energy in the boundary layer, it follows that we can prevent separation either by removing the boundary layer, or by adding energy to it. The slotted flap shown in Fig. 3.13(c) represents one simple method. The slot allows air from the undersurface to blow over the flap, so that a fresh new boundary layer is formed on the flap, helping to maintain attachment. The tired wake from the main wing element may also be re-energised by turbulent mixing with the air emerging from the slot, but this is a secondary effect.

On sophisticated aircraft, it is normal to use a flap element that slides out, thereby increasing the wing area. This type is known as a Fowler flap, and is illustrated in Fig. 3.13(d). For very high lift coefficients, the flaps may be split into two or more elements. A two-element slotted flap is shown deployed on the Tornado in Fig. 3.14, and illustrated in Fig. 3.13(e).

|

Fig. 3.14 Two-element full-span slotted flaps on the Tornado Note the large slab (variable incidence) horizontal tail surfaces The two horizontal tail surfaces can be moved differentially (one up, one down) to provide roll control, an arrangement known as a taileron. No conventional ailerons are used, so the wing trailing edge can be used entirely for flaps |