Hardware-in-the-Loop Facility

Replacing the pilot with hardware turns the flight simulator into a HIL simulation. Of course, I am oversimplifying, but the major difference is the absence of the human touch. Otherwise, both run at real time, consist of a mix of software and hardware, and are expensive to operate.

Autonomous systems, like missiles and spacecraft, operate without a human in the loop and are therefore prime candidates for HIL simulations. The control and guidance loops can be closed electronically, and any of the costly visual and vestibular stimuli are superfluous. So, what is a HIL? A HIL simulation is the dynamic representation of a vehicle in real time with subsystems modeled by a combination of hardware and software.

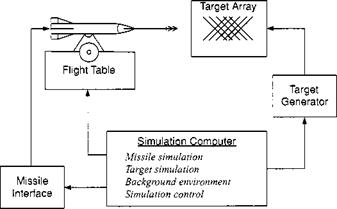

The main elements are shown in Fig. 11.13. The heart is the computer. Here reside the equations of motion and all of those features that must be mathematically

|

Fig. 11.13 Elements of an HIL simulation. |

modeled, like aerodynamics, propulsion, atmosphere, and gravity. The computer tracks the missile and target geometry and controls the event sequence. The missile attitude angles are sent to the flight table to simulate the attitude dynamics, and, through the missile interface, position and velocity are provided to the missile processor. To close the guidance loop, the missile seeker, whether IR or RF, receives the target signature from the target array, which is driven by the target generator.

There are many variations of this basic theme, contingent on the type of vehicle, availability of hardware, and purpose of investigation. The missile in Fig. 11.13 could be replaced by a cruise missile, an unmanned air-vehicle, or the kinetic kill vehicle of a ballistic missile. Depending on the development phase, we may see breadboard, brassboard, or flight-ready hardware in the HIL facility. Key hardware systems are INS, flight controller, actuator, and seeker.

HIL simulations can be used throughout the development cycle of a flight vehicle: from testing of early prototypes to system integration and acceptance testing of flight-ready hardware. Scrutinizing the interfaces between devices from various vendors can prevent much embarrassment during flight testing. (I will never forget the loss of a test vehicle over the Gulf of Mexico because of reversed polarity.)

Not all components of a HIL simulation have to be located at the same facility. For instance, if a missile is to be tested with the armament panel of an aircraft, it is impractical to park the aircraft inside the HIL facility. Instead, the aircraft is linked over fiber optic cable with the wiring harness of the missile.

The degree of distribution can be further expanded. The U. S. Army keeps tank battalions at several locations throughout the world. Each battalion uses tank simulators for training. To practice tactics without burning up fuel, several trainers are linked together to form what is called a distributed interactive simulation (DIS). Sometimes several battalions are netted together for a global training exercise. Sending time-position data over disparate telecommunication nets require tight control of the message traffic. The communication protocol that accomplishes this feat carries also the name DIS. Recently, the U. S. Department of Defense substituted DIS by HLA, a higher-order language protocol.

After this brief excursion to distributed simulations, let us discuss the requirements of an HIL facility. The system requirements are determined by the system to be tested. The apparatus should allow the system to be tested to its limits. Therefore, the bandwidth of the flight table should exceed the rigid-body frequency of the vehicle, the target model should expose the seeker to all possible frequencies with realistic noise sources and countermeasures, and the actuator should be loaded by the correct hinge moments.

Mathematical models are used for nonhardware subsystems or to back up hardware. You should by now have a good idea what they contain. Make sure to balance the model fidelity evenly across the HIL. Any or all of the components can be modeled in code. Sometimes the HIL simulation of a new vehicle can start as an all-digital simulation. As the development program progresses, hardware is substituted, as it becomes available. The computer language today is most likely C or C++, but you may have to work with legacy code in Pascal or FORTRAN or even the simulation language ACSL. Above all, it is important to establish and maintain good configuration control.

The credibility of your study depends on the extent of the verification, validation, and accreditation process preceding it. First, verify that the hardware and software performs as specified, then validate your closed-loop simulation against benchmarks and test cases from other sources. Finally, call the user to accredit your simulation by giving their stamp of approval.

The mature HIL simulation is not static. It needs maintenance and must be upgraded. The hardware needs probably more maintenance than the software, but even software in today’s volatile upgrade-driven market must be kept up to date. And who can claim a bug-free simulation? As errors are discovered, they must be eradicated and the corrective action documented. Establish a budget for maintenance and realize that upgrades are a way of life.