Smoke

The smoke consists of a suspension of solid and/or liquid particles in a gas. The required characteristics of smoke in wind tunnel applications are:

■ must not form deposits on the model or in the pipes that lead to the injectors;

■ must have a density similar to that of air: in this way, the effect of buoyancy is null;

■ must be clearly visible, non-poisonous, and non-corrosive;

■ must be inexpensive, easily produced and controllable.

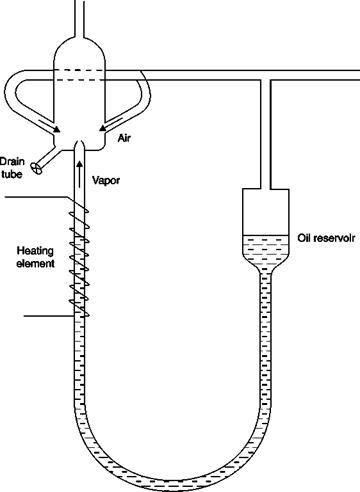

The most common methods used to produce smoke are based on the combustion of organic materials or the evaporation of a liquid. Combustion involves long preparation time and the production of solid particles forming deposits. The preferred option is the evaporation of mineral oil (e. g. kerosene) that is heated by the Joule effect in an apparatus designed by Preston and Sweeting (Figure 6.4), which is operational in

A mineral oil vapor generator

|

Mist of ▲ condensed vapor droplets

|

about 5 minutes. The adjustment of the flow of smoke to be sent to the injector is achieved by regulating the flow of air that feeds the apparatus. Sometimes the air supply is drawn from the stream in order to obtain the automatic adjustment of the injection rate of smoke to the varying speed of the stream.

The main problem presented by the technique of injecting a thread of smoke or vapor into a stream of air, or ink in a stream of water, is the

|

need not to disturb the flow. On the other hand, if well-defined filaments are needed, it is necessary that the injection speed be equal to that of the stream and at the same time that the wake produced by the injector not be turbulent. The latter requirement limits the applicability of the method at very low speeds in order to keep the Reynolds number of the injector below the critical value.

In air, the technique is used in special smoke tunnels, used for pedagogical purposes (Figure 6.5): to obtain a good contrast with the smoke filaments, one of the side walls of the test chamber is black and a system of lamps illuminates the model from above and from below. The streamlines on a stalled airfoil visualized with this technique are reported in Figure 6.6. In this case, the smoke is injected through a comb of injectors upstream of the test chamber.