Biological Flyers and Flexible Wings

Recently, efforts have been made to directly investigate the aerodynamic performance of biological flyers while accounting for the effect of flexible wing structures.

For example, Agrawal and Agrawal [518] investigated the benefits of insect wing flexibility on flapping wing aerodynamics based on experiments and numerical simulations at Re of 7.0 x 103. They compared the performance of two synthetic wings: (i) a flexible wing based on a bio-inspired design of the hawkmoth wing and (ii) a rigid wing of similar geometry. The results demonstrated that the bio-inspired flexible wing generated more thrust than the rigid wing in all wing kinematic patterns considered. They emphasized that the results provided motivation for exploring the advantages of passive deformation through wing flexibility.

Singh and Chopra [519] experimentally measured the thrust generated for a number of wing designs undergoing flapping motion at Re of 1.5 x 104. The key conclusions that stemmed from this study were that the inertial loads constitute the major portion of the total loads acting on the flapping wings tested on the mechanism and that, for all the wings tested, the thrust drops at higher frequencies. Further, it was observed that at such frequencies, the lightweight and highly flexible wings used in the study exhibit significant aeroelastic effects.

Hamamoto et al. [520] studied FSI analysis on a deformable dragonfly-like wing in hover and examined the advantages and disadvantages of flexibility at an Re of 1.0 x 103. They tested three types of flapping flight: a flexible wing driven by dragonfly flapping motion, a rigid wing (stiffened version of the original flexible dragonfly wing) driven by dragonfly flapping motion, and a rigid wing driven by modified flapping based on tip motion of the flexible wing. They found that the flexible wing with nearly the same average energy consumption generates almost the same amount of lift force as the rigid wing with modified flapping motion. In this case, the motion of the tip of the flexible wing provides equivalent lift to that provided by the motion of the root of the rigid wing. However, the rigid wing requires 19 percent more peak torque and 34 percent more peak power, indicating the usefulness of wing flexibility.

Young et al. [521] conducted numerical investigations on a tethered desert locust, Schistocerca gregaria. Their results showed that time-varying wing twist and camber are essential for the maintenance of the attached flow at the Reynolds number, 4 x 103. The authors emphasized that, although high-lift aerodynamics are typically associated with massive flow separation and large LEVs, when high lift is not required, attached flow aerodynamics can offer greater efficiency. Their results further showed that, in designing robust lightweight wings that can support efficient attached flow, it is important to build wings that undergo appropriate aeroelastic wing deformation through the course of a wing beat.

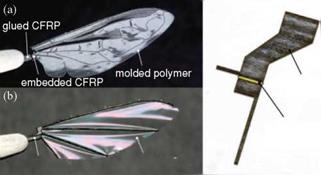

Tanaka et al. [522] investigated the effect of wing flexibility in hoverflies using an at-scale mechanical model. They suggested that at-scale models operating in air have the potential to simulate the aerodynamic phenomena of compliant flapping wings because their structure, inertia, operating frequency, and trajectories are similar to those of insects in free flight. For this purpose, an at-scale polymer wing mimicking a hoverfly was fabricated using a custom micro-molding process. It had venation and corrugation profiles that mimic those of a hoverfly wing, and its measured flexural stiffness was comparable to that of the natural wing. To emulate the torsional flexibility at the wing-body joint, a discrete flexure hinge was created. A range of flexure stiffness was chosen to match the torsional stiffness of pronation and supination in a hoverfly wing. The polymer wing was compared with a rigid, flat,

![]()

Polyester film

Polyester film

Figure 4.53. Photos of an at-scaled model wing: (a) hoverfly mimic; (b) a rigid carbon fiber model; and (c) example of hinge. The wing length is 11.7 x 103 [m]. From Tanaka et al. [522].

carbon-fiber wing using a flapping mechanism driven by a piezoelectric actuator as shown in Figure 4.53. Both wings exhibited passive rotation around the wing hinge; however, these rotations were reduced in the case of the compliant polymer wing due to chordwise deformations during flapping that caused a reduced effective AoA. Maximum lift was achieved when the stiffness of the hinges was similar to that of a hoverfly in both wing cases and the magnitude of measured lift was sufficient for hovering. These results suggest that hoverflies could exploit intrinsic compliances to generate desired motions of the wing and that, for the same flapping motions, a rigid wing could be more suitable for producing large lift.

In the next several subsections, we summarize recently reported studies based on biological models.