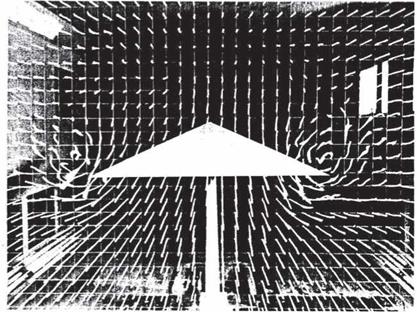

The use of a film of a non-volatile liquid is based on the principle that the film moves in the direction of the tangential stresses acting on the model.

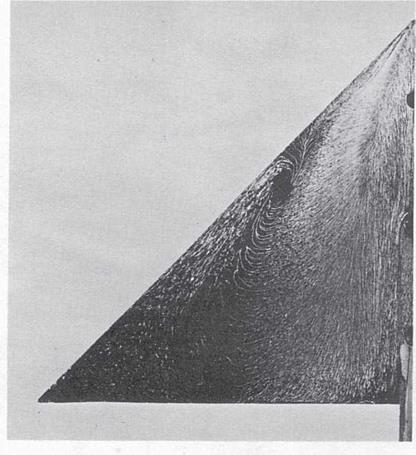

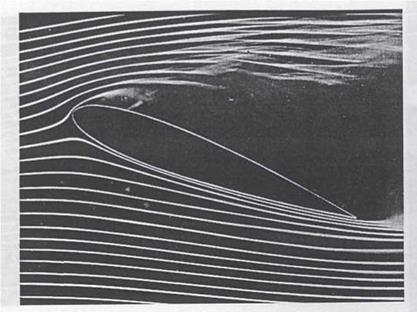

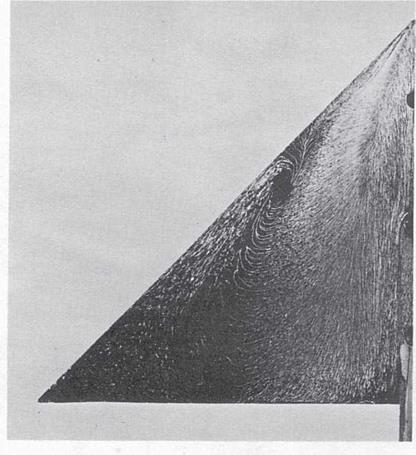

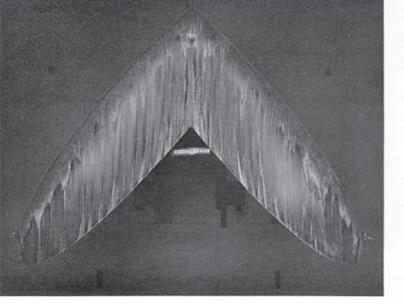

The technique is particularly suitable in visualizing surface streamlines (Figure 6.9) and flow separation (Figure 6.10). The transition can be detected as the surface stresses may be able to remove the fluid in the turbulent zone, while the laminar zone remains wet (Figure 6.11). Alternatively, before the liquid is swept away by the turbulent region, a difference can be observed in the shape of the waves on the surface of the liquid with respect to those formed in the laminar region: the wavelength is greater in the turbulent region. The latter method can be used in tests of short duration in intermittent tunnels.

The viscosity of the liquid should be chosen as a function of the speed of the tunnel and the duration of the test: the maximum viscosity is

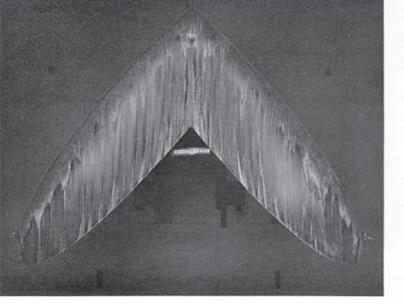

Streamlines on a delta wing visualized with an oil film (lampblack + kerosene)

|

Figure 6.9

|

|

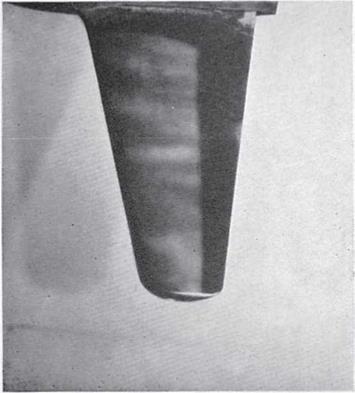

Flow separation on a sweptback wing of an orbiter model visualized with an oil film

Boundary layer transition on a double delta wing visualized with oil and titanium dioxide

|

Figure 6.11

|

|

required in tests in continuous supersonic wind tunnels. At low speeds wind tunnels are most suitable, in order of increasing viscosity: kerosene, light diesel oil, light oil for transformers. In high speed wind tunnels, often the static pressure in the test chamber is so low that liquids with high vapor pressure tend to evaporate; in these cases, oil for vacuum pumps must be used. In cryogenic wind tunnels, liquids with a low freezing point such as propane must be used.

The heavy mineral oils suitable for high speed wind tunnels are naturally fluorescent and can therefore be observed with a good contrast illuminating them with ultraviolet lamps; lighter oils can be made more observable using fluorescent additives.

An alternative is the addition of pigments: lampblack on clear models, white pigments such as titanium dioxide (Figure 6.11) or kaolin on dark models. An additive, e. g. oleic acid to titanium dioxide, is usually used to control the flocculation of the paint. One advantage in using the oil— lampblack mixture is the fact that it can be stored in bottles for an indefinite time. The mixture of titanium dioxide or kaolin and oil is instead a real paint: it tends to dry in the air and therefore it must be prepared just in time for each test.

To avoid the parallax error that would be made if photographing curved surfaces, the model can be covered with a self-adhesive plastic – coated white paper on which the oil-lampblack mixture is applied; after the test, the paper is removed and made plane before photographing. Alternatively, on completion of the test, the produced pattern is removed with a transparent adhesive sheet that is then photographed and possibly stored for later analysis.

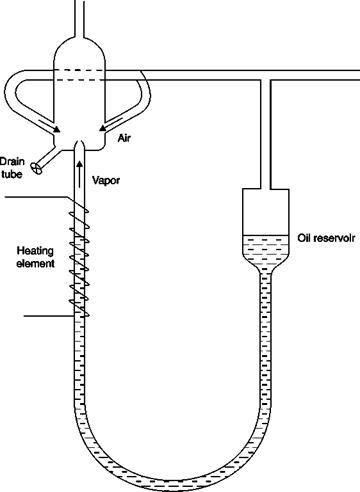

![]() Boundary layer transition visualized with a sublimating material

Boundary layer transition visualized with a sublimating material