Hypersonic flight using a scramjet engine has been something of an aeronautical engineer’s dream ever since the late 1960s. The American National Aerospace Plane (NASP) programme involved building a prototype, the X-30 research aircraft. However after some 2.4 bn dollars was spent of the project,

|

Fig. 8.24 Hypersonic scramjet-powered flight

The small X-43A unmanned scramjet-powered hypersonic research aircraft which achieved Mach 9.68 in 2004

|

it was abandoned in 1994. This project was then followed by a lower cost approach involving the use of an unmanned 12 ft long vehicle, the X-43, shown in Fig. 8.24. This was mounted on the nose of a Pegasus booster rocket, and the combination was launched from under the wing of a B52 bomber. After a major failure in the first flight, two later successful flights were made, with the X-43A finally reaching a maximum speed of Mach 9.68 in 2004, after a fuel burn of some 11 seconds. The viability, though perhaps not yet the financial practicability, of scramjet-power hypersonic flight was thus established.

Recommended further reading

Kdchemann, D., The aerodynamic design of aircraft, Pergamon Press, 1978, ISBN 0080205143. A masterpiece from the ‘Father of Concorde’ which stands the test of time. Peebles, C., Road to Mach 10: Lessons learned from the X-43A flight research program, AIAA, Reston VA, USA, 2008, ISBN 9781563479282. A fascinating and detailed description of the X-43 project.

Flight in the range between the onset of important compressibility effects (M = 0.7) and the establishment of fully supersonic flight conditions on the other side of the drag coefficient rise (M = 1.4) is said to be transonic. The transonic range poses some of the most difficult problems for the aerodynamicist but it is of great practical importance. Not only do supersonic aircraft need to have satisfactory characteristics to accelerate and decelerate safely through the transonic range but currently many aircraft are designed to cruise close to the speed of sound.

The reason for this has been given in previous chapters. Because the efficiency of a gas turbine engine increases with design speed, we wish to fly fast. However, as the speed of the aircraft approaches the speed of sound a sudden rise in drag occurs, together with other problems such as the production of sonic bangs on the ground. For most transport aircraft, and a number of military aircraft designed for such roles as ground attack, a suitable solution is obtained by restricting the cruising speed to just below the drag-rise Mach number.

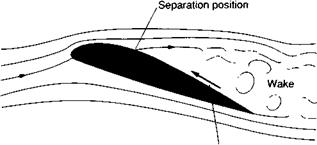

In Chapter 5 we saw how compressibility effects and shock waves put up the drag as the speed of sound is approached. For a given aircraft the typical variation of drag with Mach number is shown in Fig. 5.19. The very rapid increase in drag coefficient near the speed of sound is clearly shown. Some wing sections also produce a slight dip in drag immediately before the rise. Figure 9.1 shows this effect. It is caused by the rise in lift coefficient in Fig. 5.19 which offsets the smaller rise in drag coefficient initially for a wing operating at constant lift rather than constant angle of attack.

At first sight it might seem to be best from the point of view of obtaining economical cruise conditions to keep well below the drag rise Mach number. However as we saw in Chapter 3, the efficiency of the gas turbine rises with Mach number and it is therefore worth pushing the cruising speed as close to the speed of sound as possible to obtain the best compromise between airframe and engine performance. It may also be worth exploiting the drag coefficient ‘dip’, mentioned above, at the same time.

|

Fig. 9.1 Transonic drag rise at constant lift

|

These factors have resulted in the development of a whole series of airliners cruising at a speed just below that at which the transonic drag rise occurs. This has had the added advantage of providing the travelling public with high speed transportation over a wide variety of distances – and one of the most appealing features of air transport has always been speed.

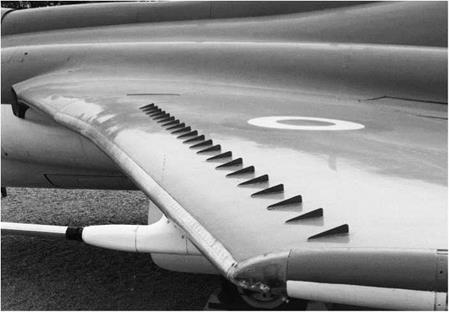

In this chapter we will consider the aerodynamic development of aircraft designed for flight at transonic speeds, with particular emphasis on the problems associated with transport aircraft. However it must not be forgotten that many military aircraft, such as ground attack aircraft (Fig. 9.2) are also designed primarily for transonic operation and some reference will also be made to these where appropriate.

The development of civilian transport aircraft over a period of some 30 years is illustrated in Fig. 9.3 in which two aircraft are shown spanning the period from the earliest jet transport, the de Havilland Comet, to a much later design, the Airbus A340. An intermediate development, the Trident is shown in Fig. 3.9. In some ways the three configurations look remarkably similar, the main obvious development being the introduction of pylon mounted engines rather than the buried installation of the Comet. Closer examination, however, reveals other changes. Firstly there has been a reduction in the plan – form area of the wing for a given aircraft weight; in other words an increase in the wing loading. Next there has been a tendency for the sweep angle firstly to increase but, surprisingly to be reduced in the more modern designs. Close examination of the aircraft themselves would also reveal considerable differences in the wing sections used.

The choice of sweep angle is a question of a compromise between using enough sweep to reduce the effects of compressibility, as will be explained below, and avoiding the unpleasant low speed handling effects (Chapter 2).

|

Fig. 9.2 The BAe Hawk doubles as a trainer and a transonic ground attack combat aircraft. The wings have moderate sweep and aspect ratio

|

The reason for wishing to use high wing loading simply comes from the need to reduce area for a given weight, and the need for this was discussed in Chapter 8.

As we have seen previously, all aircraft design is a compromise, and the actual minimum area may well be dictated by landing requirements rather than cruise requirements. The increase in wing loading thus owes a great deal to the work of the low speed specialist in producing ever more sophisticated and effective high lift devices for use during take-off and landing. Some of these have been described in Chapter 3, and this is likely to be a major field of aerodynamic research and development for some considerable time.

Even the term ‘low speed specialist’ used in the above paragraph must be treated with some caution. The aircraft may itself be flying at low speed in the sense that the speed of flight is well below the speed of sound. However, extremely low pressures may well be developed over the upper surface of such devices as leading edge slats, and what at first sight may appear to be a low speed flow, may well contain localised regions in which the flow is near to, or even exceeds the speed of sound.

After this slight digression into the necessary problem of ‘off design’ performance, we now return to the problem of designing a wing with good performance at the cruise condition. At this stage it is worth emphasising that, for the type of aircraft we are considering, the cruising speed will be just below the speed of

|

Fig. 9.3 Transonic airliner development

More than thirty years separate the Comet (upper) with a maximum wing loading of 3.61 kN/m2 (75.5 lbf/ft2), and the Airbus A340 (lower) with a maximum wing loading of 6.85 kN/m2 (143 lbf/ft2)

|

sound, in order to avoid the full effects of the transonic drag already described. The basic problem is therefore to try to push the wing loading as high as possible, while at the same time delaying the onset of this drag rise to as high a Mach number as possible. The requirement for high-wing loading implies low local pressures on the upper surface of the wing, and consequently high local speeds. These high speeds, however, are the very thing that is likely to lead to the formation of shock waves which cause the transonic drag rise. It is to the problem of resolving this dilemma that we now turn our attention.