Aircraft parameter estimation

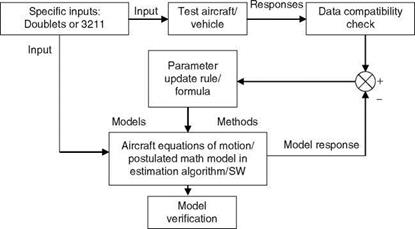

One important aspect of flight-testing of any aircraft or helicopter (or even a missile) is to generate the data for estimation of its stability and control derivatives. In this sense, parameter estimation is an important tool for flight test engineers and data analysts to determine the aerodynamic characteristics of new and untested aircraft. Flight-estimated derivatives are very useful in updating the flight simulator models (of aircraft), improving the flight control laws, and evaluating handling qualities. In addition, flight-determined derivatives (FDDs) help in the validation of the predicted derivatives, which are based on one or more of the following: (1) wind-tunnel experiments on scaled models of aircraft and subsequent data reduction methods; (2) DATCOM (Data Compendium) methods; and (3) some analytical/CFD methods. The aircraft dynamics are modeled by a set of differential equations. The external forces and moments acting on the aircraft are described in terms of aircraft stability and control derivatives, which are treated as unknown parameters. Responses of the test aircraft and the mathematical model are obtained and compared using specifically designed control inputs. An appropriate parameter – estimation algorithm is applied to minimize the error (in responses) by iteratively adjusting the model parameters. The key elements—maneuvers, measurements, methods, and models—play an important role in aircraft parameter estimation (Figure 9.1). Assume that a set of measured flight test time histories are given; the parameter-estimation problem is thus to determine the values of a given set of parameters in the system equations (postulated model), which will provide the best match of the model responses to actual aircraft responses, in either LS or minimum mean square error sense. There are several methods for the estimation of aircraft parameters and the basic differences are due to certain assumptions, choice of optimal criteria, formulation of cost function that reflects the existence of external disturbances, and the presence of measurement noise in the data.

9.3.1 Maneuvers, Measurements, and Mathematical Models

A detailed description of maneuvers that are to be performed specifically for generating data that are suitable for aircraft parameter estimation was presented in Chapter 7. The first major step in aircraft parameter estimation is the definition and planning of flight test experiment and subsequent data acquisition. This primarily addresses the issue of specification of flight test maneuvers and obtaining measurements of control surface deflections, airspeed, sideslip, angle of attack (AOA), angular velocities, linear and angular accelerations, and attitude angles. Also, definition of flight conditions, aircraft configuration, sensors, fuel consumption for estimation of aircraft, CG location, weight, and inertias is required. Detailed information about these must be sought before the analysis of the flight data.

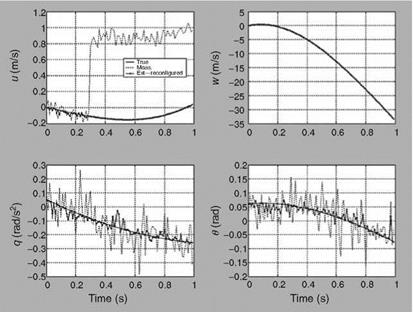

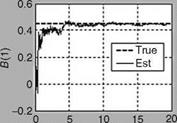

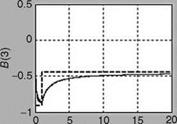

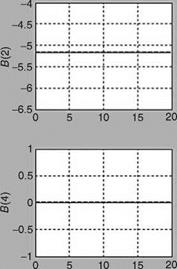

The accuracy of estimated derivatives depends on the quality of measurements that are subjected to systematic and random errors. It is essential to evaluate the quality of the measured data and rectify these measurements before using them for parameter estimation. These evaluations include consideration of factors like the frequency content of the input signal, sampling rate, signal amplitude, and signal-to – noise ratio. Some quantities may be difficult to measure directly, such as vibration levels in helicopters. As a first step, the raw data is inspected for obvious gross errors and imperfections, such as incorrect signs of measured variables, missing points, spikes, and extensive noise. The corrections are made in data to account for errors resulting from sensor location (e. g., CG offset and flow corrections) and time-skew errors. The procedure for evaluating data quality and correction is the kinematic consistency checking; as the aircraft states are related by a set of differential equations, one checks for consistency among the kinematic quantities. As an example, the measured roll and pitch altitudes should match with those reconstructed from the rate measurements with great accuracy. The process ensures that the data are consistent with the basic underlying kinematic models; since the aircraft is flying, it must be according to the kinematics of the aircraft, but the sensors could have gone wrong in sensing/generating the data. The data compatibility check provides the estimates of the bias parameters and scale factors in the measured data. An accurate determination of these errors is very important for accurate estimation of the aerodynamic derivatives from flight data.

The mathematical models used in aircraft parameter estimation are discussed in Chapters 3 through 5 and specifically simple longitudinal and lateral-directional (LD) models are discussed in Chapter 5. If the modes of aircraft dynamics are not properly excited by the chosen input, then an attempt to identify too many parameters from a limited amount of data might fail or yield estimates with reduced accuracy.

The response of an aircraft to pilot’s (or computer’s) command signal is the flight data that along with other mandatory data (mass, inertia, dynamic pressure, etc.) are used in a parameter-estimation procedure to estimate the aerodynamic derivatives. These responses are generated by exciting certain modes of the aircraft. These modes

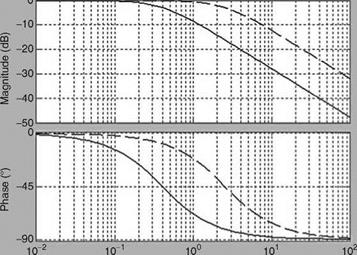

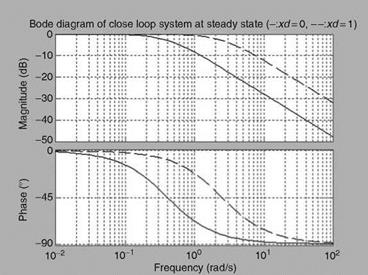

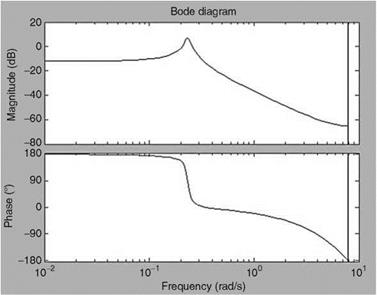

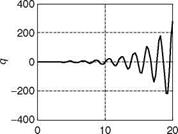

are dynamic modes and they contain information on the aerodynamic derivatives implicitly. It is essential to choose input test signals with good characteristics so that properly excited dynamic responses are available for further analysis. The test input signal must possess certain desirable features: (1) it should have sufficient bandwidth to be able to excite the modes of interest; (2) the amplitude and form of the signal should be able to yield good quality maneuver; (3) the amplitude, bandwidth, and slope of the signal should be bounded so that aircraft motion does not violate the assumption of linearity; and (4) the pilot should be able to realize (generate) the signal easily. Of course, for complicated signals computer simulation or prerecording can be used. To design a multistep input signal, which will excite the modes of an aircraft, one can use the Bode diagram approach [13]. This allows one to select the frequencies to be included in the signal based on the identifiability of the derivatives.

If the two models are equally likely (L1 ~ L2), then the one with less number of parameters is chosen again according to the principle of parsimony. If the number of parameters increases, the AIC also increases, and hence the model is less preferable.

If the two models are equally likely (L1 ~ L2), then the one with less number of parameters is chosen again according to the principle of parsimony. If the number of parameters increases, the AIC also increases, and hence the model is less preferable.

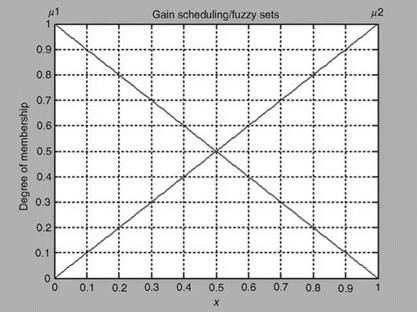

is the normalized degrees of fulfillment. Now the fuzzy control

is the normalized degrees of fulfillment. Now the fuzzy control