Takeoff and Landing Tasks

Takeoff and landing tasks are always critical for any aircraft. Since the aircraft would be carrying some loads, cargo, passengers, etc., for the takeoff task, the required high speed must be reached before the wings can generate the sufficient lift to balance the weight, and hence it has to travel a long distance on the runway [6,10]. The landing may be required at any time. The aircraft may have to land on a short runway.

7.2.2.1 Approach and Landing Task

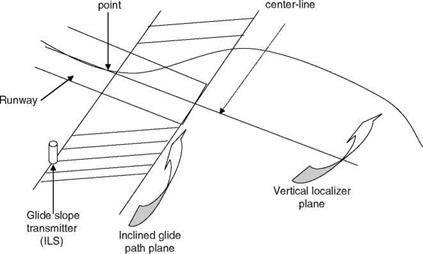

The landing-related portion consists of approach, flare, and landing. Normally, the approach altitude is 16 m (50 ft). This is a very crucial task, for which first the aircraft is maneuvered into a certain vertical plane called the ‘‘localizer’’ plane that is generated electronically by the ILS (instrument landing system) [6]. While in level flight, once intercepted, the nominal path intersects with a second ILS-plane called the ‘‘glide path’’ plane, the baseline of which is perpendicular to the runway centerline as shown in Figure 7.2. The intersection of the two ILS-planes provides the glide path or glide slope. The pilot concentrates his or her attention on the primary flight instruments and the ILS deviation indicator during the following sequentially interconnected flight phases: (1) the first interception, (2) tracking of the localizer, and

|

Aircraft landing touch-down Runway

FIGURE 7.2 Landing flight path for an aircraft. (From Mooij, H. A., Criteria for Low Speed Longitudinal Handling Qualities (of Transport Aircraft with Closed-Loop Flight Control Systems), Martinus Nijhoff Publishers, The Netherlands, 1984.) |

(3) getting into the glide path. The pilot decelerates the aircraft and gets into the landing configuration (while lowering the undercarriage), at the same time counteracting atmospheric disturbances and any other deviations. While switching to the outside visual scene, the pilot initiates the landing by gradually rotating the aircraft. The velocity vector virtually changes into horizontal direction. The aircraft is flown with the main (rare) wheels against the runway surface and a soft and positive touchdown is made. The nose wheel is then lowered to make ground contact and the aircraft is decelerated to the taxi speed. The ground portion of the landing consists of aero/wheel braking and stop. The pilot should be able to minimize the distance required to land. Some very crucial conditions of the landing are (1) testing the landing for various weights, (2) height/elevation, and (3) the brakes are most important ingredients and must be evaluated for their precise performance. The data/information generally required are airspeed, pressure altitude, distance along the runway; engine revolutions per minute (rpm), temperatures/pressure measurements; and wind-related measurements.

7.2.2.2 Takeoff Task

The takeoff is also very critical task. This task is divided into two portions: (1) the ground acceleration and (2) takeoff/climb. The pilot uses a suitable method for the first segment, based on the flap settings, control settings, and steering methods. He or she will accelerate the aircraft sufficiently to obtain sufficient speed and then apply the stick control to obtain the best altitude for takeoff. When the aircraft is airborne the speed will be controlled to obtain the best angle for the climb. The landing gear would be retracted to reduce the drag effects. For trial fights the landing gears are kept in down position. The rotation maneuver should be smooth and the pilot should acquire and maintain the speed for best angle of climb. The takeoff and climbing tasks should be carried out for a few possible climb speeds and deployment of flaps. The pilot should minimize the distance required on the runway to takeoff. The required data/information are almost similar to that required for landing.