Groupings of Aerofoils and Their Properties

From the early days, European countries and the United States undertook intensive research to generate better aerofoils to advance aircraft performance. By the 1920s, a wide variety of aerofoils appeared and consolidation was needed. Since the 1930s, NACA generated families of aerofoils benefiting from what was available in the market and beyond. It presented the aerofoil geometries and test results in a systematic manner, grouping them into family series. The generic pattern of the NACA aerofoil family is listed in [4] with well-calibrated wind-tunnel results. The book was published in 1949 and has served aircraft designers (civil and military) for more than a half-century and is still useful. Since its publication, research to generate better aerofoils for specific purposes continued, but they are made in the industry and are “commercial in confidence.”

Designations of the NACA series of aerofoils are as follows: the four-digit, the five-digit, and the six-digit, given herein. These suffice for the purposes of this book – many fine aircraft have used the NACA series of aerofoils. However, brief comments on other types of aerofoils are also included. The NACA four – and five-digit aerofoils were created by superimposing a simple camber-line shape with a thickness distribution that was obtained by fitting with the following polynomial [4]:

y = ± (t/0.2) x (0.2969 x x0 5 – 0.126 x x – 0.3537 x x[1] + 0.2843

x x[2] – 0.1015 x x[3]) (3.20)

NACA Four-Digit Aerofoil

Each of the four digits of the nomenclature represents a geometrical property, as explained here using the example of the NACA 2315 aerofoil:

|

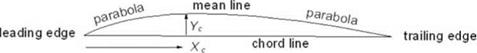

Figure 3.11. Camber line distribution |

The camber line of four-digit aerofoil sections is defined by a parabola from the LE to the position of maximum camber followed by another parabola to the trailing edge (Figure 3.11). This constraint did not allow the aerofoil design to be adaptive. For example, it prevented the generation of an aerofoil with more curvature toward the LE in order to provide better pressure distribution.