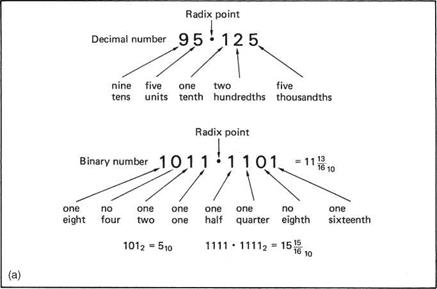

The power plant is an important component in all aircraft and no less so in helicopters. However, helicopters necessarily have a more complicated power transmission system than aeroplanes. In this chapter the choice of power plant is considered, along with the operating principles of piston and turbine engines and associated transmissions. Power plant control and instrumentation is also treated.

|

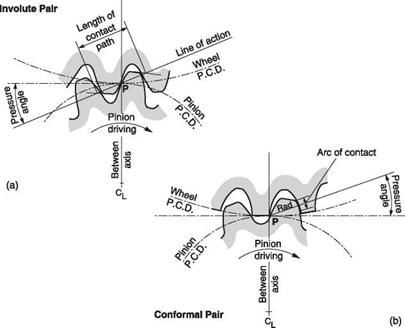

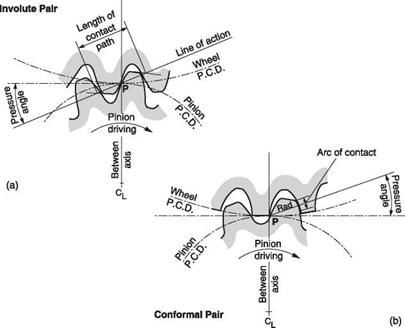

The power source of a conventional helicopter must be able to drive a shaft, and have reasonable weight and fuel consumption in relation to the power delivered. This generally means an internal combustion engine: piston, rotary or turbine. Real engines always turn too fast for real rotors and some reduction gearing will be needed to transmit engine power to the various rotors and accessories. There have been some exceptions to convention. Numerous efforts have been made to fit rockets, ramjets or turbojets directly to the blades, or even to duct gases into the blades from the hull. The goal is to eliminate torque reaction and reduce weight. These alternatives are considered in section 6.28.

|

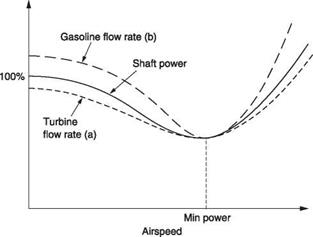

All internal combustion engines work by burning fuel in air. This raises the temperature, causing expansion which can do work. In practice more power can be obtained if the air is compressed before the fuel burns. The turbine engine has dominated the helicopter power plant market for some time. The main advantage of the turbine is a very high power to weight ratio. The lightness comes from simplicity; the compression of air and the extraction of shaft power are both done by rapidly spinning blades. There is, however, a penalty for that simplicity which is that the fast moving blades suffer from profile drag. Just keeping the blades moving consumes power. When used at high power, the internal power loss is a small part of the overall power produced and the turbine is efficient. When used at lower power, the power lost in the blades does not reduce in proportion and so the efficiency falls. Small turbine engines tend to be inefficient because the Reynolds numbers at which small blades must operate will be less favourable. As a result there are very few small turbine engines and these tend to be used as APUs (auxiliary power units) that are only used intermittently. Although simple in concept, the turbine engine uses highly stressed parts and the initial cost is high.

Statically compressing air with a piston in a cylinder suffers much less power loss than dynamic means such as a turbine. This makes piston engines more efficient at partial throttle settings, hence their popularity in automotive applications. The energy released on each power stroke is finite and so a good way of increasing the power is to increase the RPM. The piston engine must handle the stresses raised by reciprocating that increase with the square of the RPM.

This limits the RPM available as a function of piston size. Very small piston engines used in models can run at over 25 000 RPM and produce an astonishing power to weight ratio, but this cannot be scaled up because of the forces involved. Another fundamental of piston engines is that the power available is a function of the charge that can be admitted to the cylinder. The cylinder volume is proportional to the cube of the bore whereas the cylinder head area, where the valves are, is only proportional to the square of the bore. As a result the small cylinder has the advantage because not only is the piston lighter, but more valve area is available in relation to the displacement. Thus in piston engines there is a power to weight advantage in using a lot of small cylinders rather than a few big ones. There is an optimum cylinder capacity for a given RPM. The difficulty is that in order to produce a lot of power, a lot of cylinders are needed and this causes practical difficulties in induction, exhaust, cooling and reliability, to say nothing of cost. During World War II aircraft engines having as many as 28 cylinders were built and these were immensely complicated.

At 400-500 kW the turbine and piston engine are about equal. For higher powers the turbine is to be preferred, whereas for lower powers the piston engine would be chosen. The power to weight ratio may not be as high, but if the fuel efficiency is good, the saving in fuel load may more than compensate. As a result, helicopter design has diverged into two camps. Large machines use two or three turbine engines and tend to use high disc loading because plenty of power is available. Small machines use piston engines and lower disc loadings.

In between the extremes there is some variability. The small single-engine turbine helicopter cannot use high disc loading because it must be designed to autorotate well. As a result it will not need much power and so the turbine will be heavily derated and have poor fuel efficiency. Unfortunately derating an engine does not lower the cost. Well-engineered piston machines can compete in this market simply by costing less to purchase and less to run. Frank Robinson has demonstrated this amply with the R-44, despite its elderly engine technology.

Unfortunately the aviation piston engine went into a period of stagnation for several decades after the arrival of the turbine, with the result that progress in piston engine development moved to the automotive sphere. This situation is now being remedied and a new generation of aviation piston engines will give helicopter designers some better solutions in light machines. In the automotive sphere fuel economy does not drastically improve performance because the fuel load is a relatively small proportion of the vehicle weight. In helicopters the fuel weight at take-off is limited by available rotor thrust. Thus an improvement in fuel efficiency in the helicopter will translate directly into either an increase in range for the same payload, or an increase in payload for the same range.

The power of the gasoline engine is controlled by an induction throttle, and when this is used, the effective compression ratio of the engine falls and with it the efficiency. The induction throttle reduces the manifold pressure and this opposes the motion of the piston during the induction stroke causing pumping loss. The power of the Diesel engine is not controlled with a throttle. There is negligible pumping loss and the compression ratio is always at its highest value. As only air is compressed, there is no risk of detonation and the compression ratio can be very high indeed. This makes

the Diesel fundamentally more fuel efficient than the gasoline engine as will be seen in section 6.14. Traditionally, however, the Diesel engine has been neglected in aviation although some Diesel powered aircraft flew in World War II. The automotive industry has dramatically improved Diesel performance in recent years and has shown that the Diesel engine lends itself very well to turbocharging. With modern technology the turbo-Diesel engine can equal the power of a gasoline engine for a given time between overhaul (TBO), but with better fuel economy so that the weight of engine plus mission fuel is actually less. Given that Diesel engines can run on AVTUR, which is significantly cheaper and less volatile than AVGAS, the economic and safety advantage of a Diesel engine is significant.

|

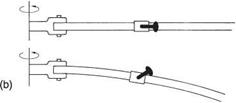

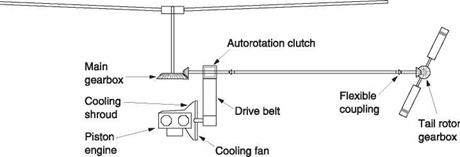

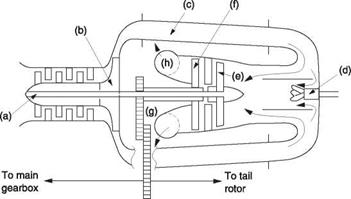

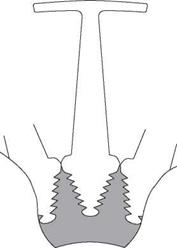

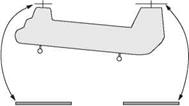

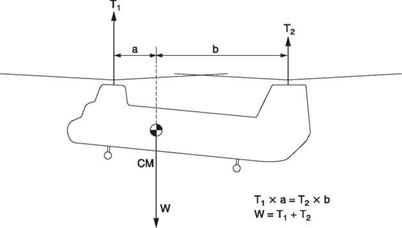

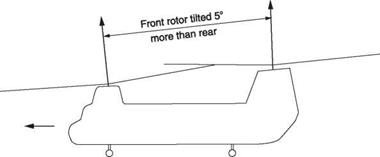

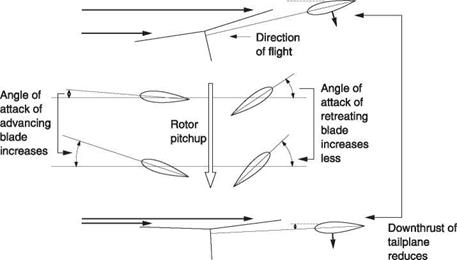

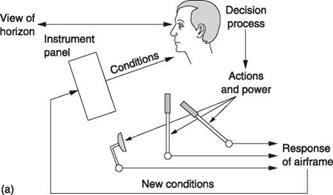

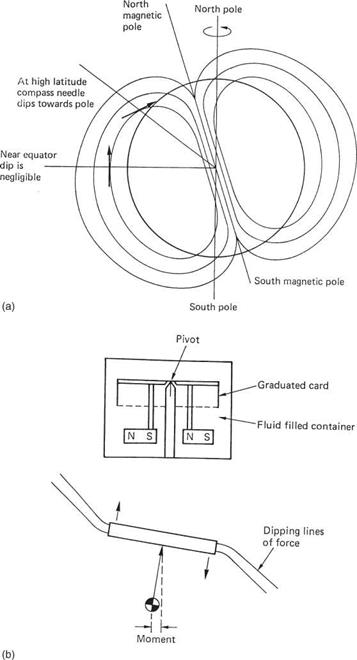

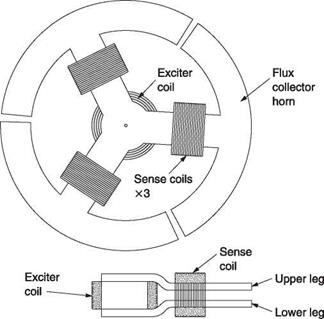

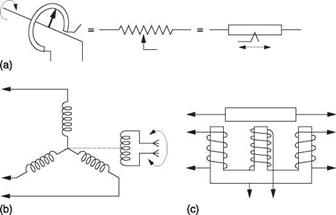

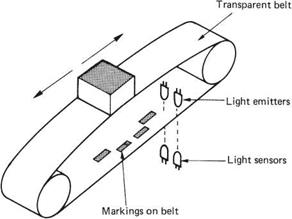

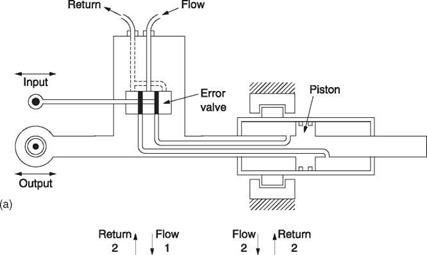

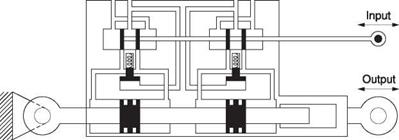

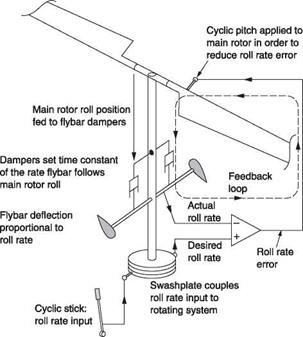

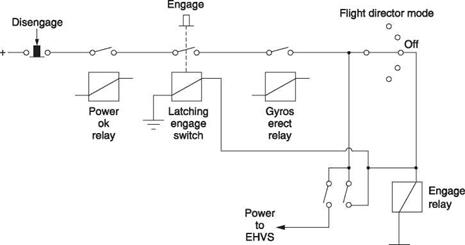

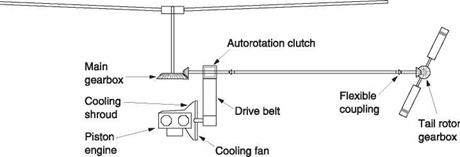

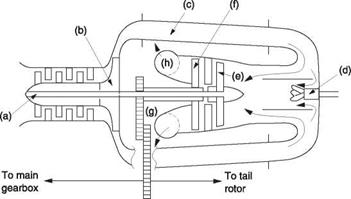

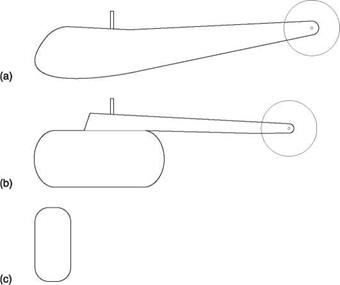

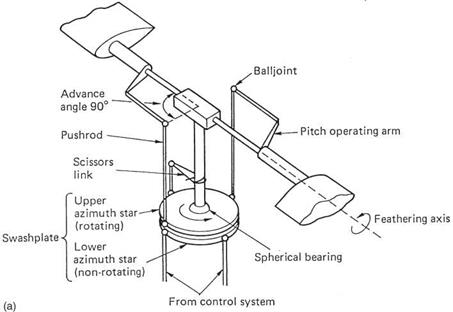

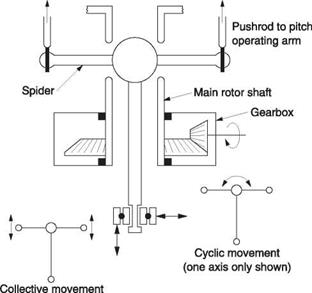

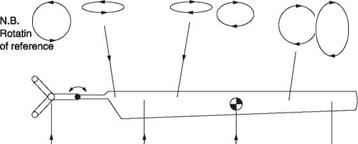

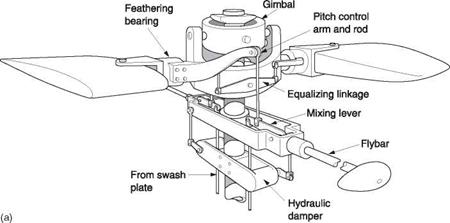

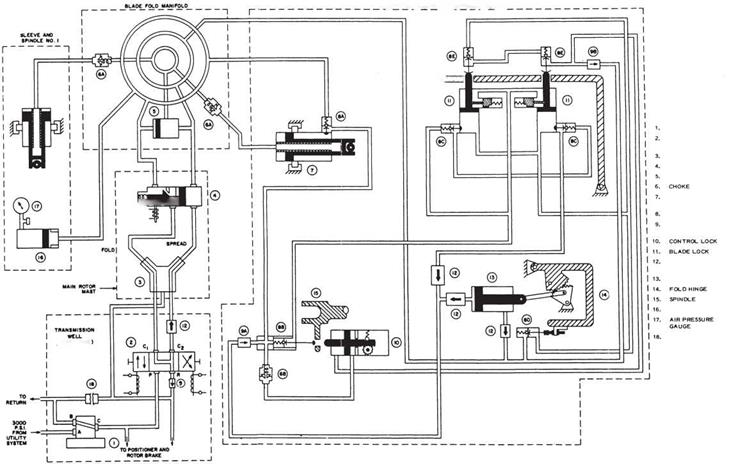

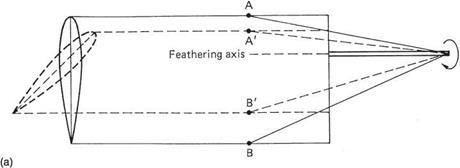

Figure 6.1 shows the layout of the engine and transmission in a typical light piston – engine machine. Many light helicopters use an air – and oil-cooled engine originally designed for aeroplane use in which the crankshaft will clearly be horizontal. These typically have four cylinders arranged with a pair on each side. This arrangement is called a ‘flat four’ also known as a ‘boxer’ because the pistons on opposite sides appear to be sparring with each other. The propeller is replaced by the cooling fan and possibly a belt drive pulley. The cooling fan directs air through a series of baffles so that it passes round the cylinders. Some of the air is directed through the oil cooler. The centrifugal cooling fan of the Robinson R-22 is a conspicuous feature of the machine. The Enstrom has an axial fan.

Piston engines do not provide uniform torque because of the power impulses when each cylinder fires, and it is necessary to have some flexibility in the transmission to even out the power delivery. Even so, the transmission of a piston-engine helicopter has to be stronger to withstand the fluctuating torque. The use of anti-vibration technology in the drive train to smooth out the power impulses of piston engines with torsional tuned filters is in its infancy. Currently, flexibility in the drive train may be provided by using a belt drive and by mounting the engine on rubber blocks. The belts used are reinforced with polyester chords and have a tapering cross-section intended to run in vee-shaped grooves in the pulleys. Belt tension wedges the belt into the groove so that

|

Fig. 6.1 The drive train arrangement used in a number of light piston-engine helicopters including Robinson, Enstrom and Schweizer models. The piston engine drives a cooling fan and a belt pulley. The belt drives a shaft between the main and tail gearboxes. The upper pulley contains a one-way clutch to allow the rotors to turn if the engine fails.

|

slipping will not occur. Machines vary in detail; the Robinson uses two double-vee belts, the Schweizer uses eight single belts, and the Enstrom uses a single Poly-vee belt about six inches wide. Belts can last as long as five years, but flying in dusty conditions causes more rapid wear.

The belt drive commonly does duty as the clutch. By slackening the belt tension, the engine can be started and warmed up without the rotors turning. When the engine is warm the belt tension is applied gradually so that the belt can slip in order to spin up the rotors smoothly. Once the rotors are up to engine speed the full flight tension can be applied. Starting the engine with the clutch engaged should never be attempted. In the Robinson the starter is powerful enough to turn engine and rotors, but when the engine fires the sudden speed increase could damage the main rotor blades. In an Enstrom the rotor blades are heavy and articulated and instead the result would probably be a burned-out starter.

The belt tensioning is performed in various ways. In the Robinson the shaft between the main and tail rotors is supported near the pulleys by a bearing that can be raised and lowered by a small electric gear motor. The flexible couplings in the shaft allow this movement. The belt tension is measured and the motor can only run until the correct tension is achieved. Some care is needed when operating the motor switch; rapid engagement will stall the engine. In the Enstrom the belt is tensioned by bringing in a jockey pulley against the flat outer side of the belt. This is mechanically operated by cable from a lever in the cockpit. When the drive is fully engaged a system of links passes over centre and maintains belt tension with no tension in the cable. In this system the pilot has better control of the clutch engagement force. In the Schweizer the belts are tightened by pulling out an idler pulley with a steel wire driven by a servo motor. The wire is permanently in tension. In all of these machines, the upper belt pulley drives the long shaft joining the main rotor gearbox and the tail rotor gearbox.

The pulley on the gearbox shaft has a one-way clutch inside it so that the engine can drive the shaft but the shaft cannot drive the engine. If the engine fails, or, worse still, siezes, the rotors can still turn freely so that an autorotation can be performed.

|

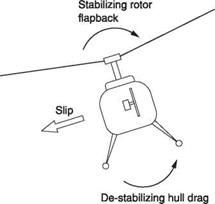

As will be seen in section 6.19, turbine engines are found in two types. In the first there is only one rotating assembly and this is integral with the output shaft. No starting clutch is necessary because the starter motor spins the turbine and the rotor. In the preferred type of turbine engine there are two power turbines. The first generates shaft power to turn the compressor. The second turbine develops shaft power to drive the helicopter. Engines of this type are called free turbine engines because there is no mechanical connection between the first part of the engine, which is essentially a gas generator, and the second part that converts gas energy to shaft power. The gas generator may be spun with the starter motor even though the free turbine is locked by a rotor brake. In this way the engine can be started without the rotors turning. If the brake is released and the power is increased, the rotors will run up smoothly. The free turbine engine also has the advantage that the rotors can be stopped without stopping the engine. The turbine is set to idle power and produces minimal torque at the free turbine. The rotor can be stopped with the rotor brake.

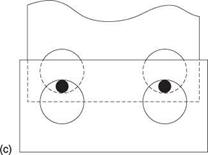

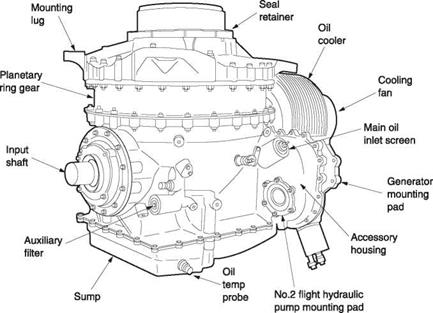

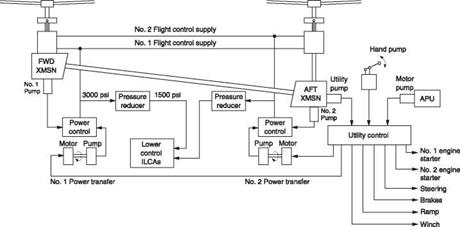

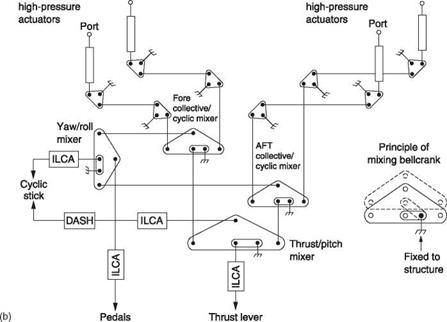

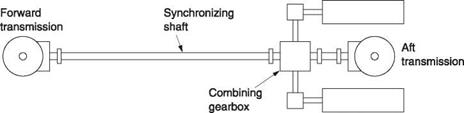

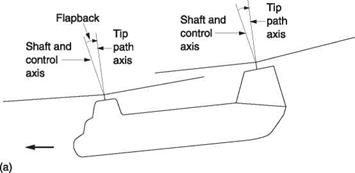

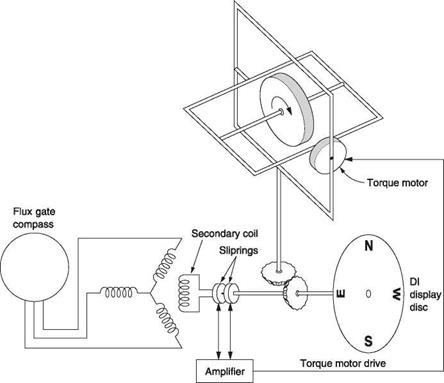

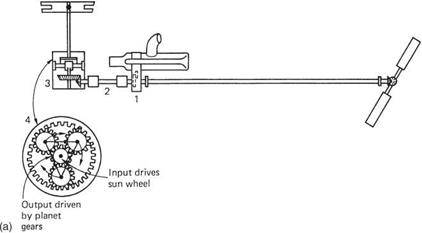

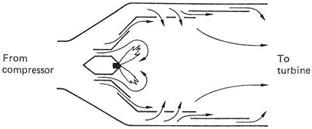

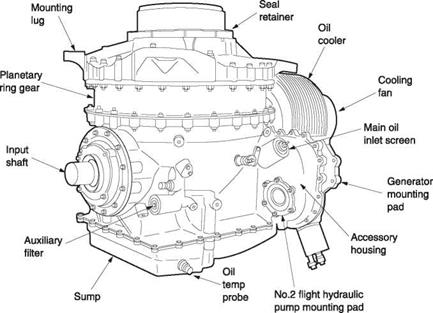

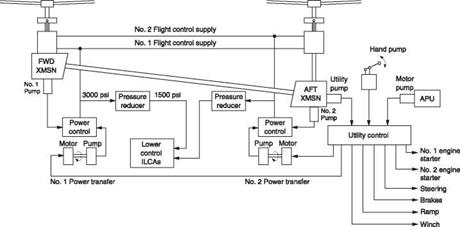

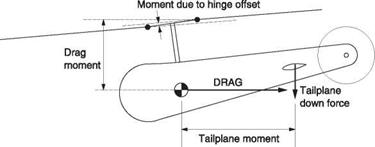

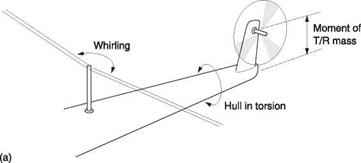

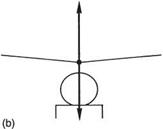

The turbine itself is light and often mounted on or in the roof of the hull. Figure 6.2(a) shows the arrangement in the JetRanger. The power turbine gear train, through the autorotation clutch, drives the tail rotor shaft to the rear and the main rotor shaft to the front. The main rotor gearbox is resiliently mounted and the drive shaft is fitted with

two constant velocity joints to allow relative motion of the gearbox and the engine. In some machines the turbine drives only the main transmission as in Figure 6.2(b). In many machines twin engines are installed. In this case a pair of autorotation clutches is needed, one for each engine. Then either engine can fail and the remaining engine drives the transmission. The tail rotor drive must also come from the transmission.

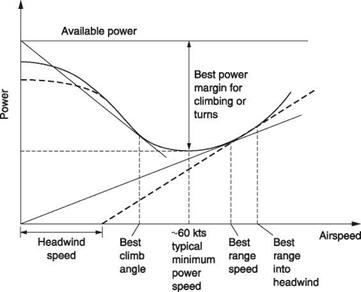

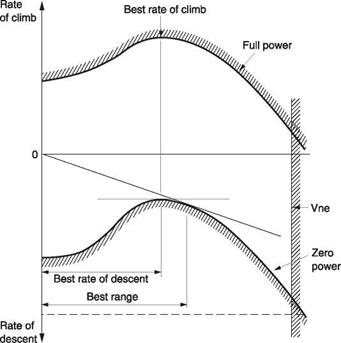

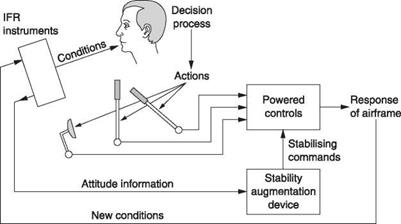

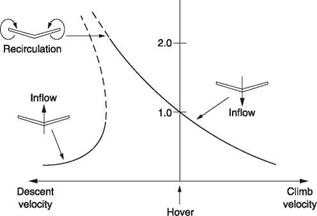

The RRPM determines the rate of response to the controls and must be kept constant. It was shown in Chapter 3 that the power needed to drive the rotors at constant speed varies considerably with the attitude and flight regime. Governors and correlators are devices intended to make control of the throttle more or less automatic so that the pilot has less to do. The governor is a system using negative feedback to adapt the power

setting to the load placed on the engine. In contrast the correlator is a device using feedforward to predict the power setting necessary from the position of the collective lever. This may be done mechanically with a shaped cam on the collective linkage. The cam shape is obtained during tests of the prototype. Feedforward may also be applied electrically, in which case the collective lever is fitted with a position sensor. A correlator only gives an approximate control of RRPM since the position of the collective lever is only one factor affecting the power required. There is, for example, no compensation for air density or the degree of inflow through the rotor.

The gasoline engine is literally throttled to control its power. The induction passage is restricted and this is a stable process. If the engine speeds up, the pressure drop across the constriction will increase, dropping the induction pressure. If the engine slows down, the pressure drop across the constriction will decrease, increasing the induction pressure. Thus on a piston-engine helicopter governors are not essential and most machines just have a correlator. One school of thought suggests that it is better to learn to fly an uncorrelated machine because by manipulating the throttle a more thorough understanding of the power needed in different conditions is obtained.

Neither the turbine nor the Diesel has a throttle because the induction system is fully open at all times. As a result these types of engine will not hold their RPM unaided and a governor is essential. The governor is a system that compares the desired speed with the actual speed and uses the speed error to operate the power control to apply a correction. This is an example of negative feedback as described in Chapter 2.

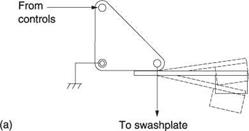

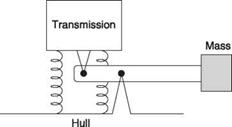

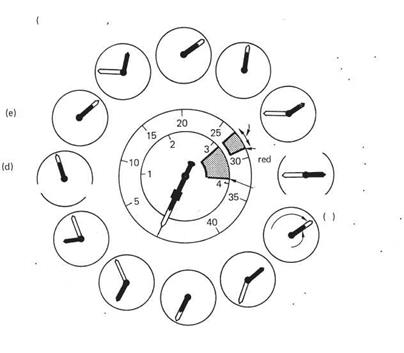

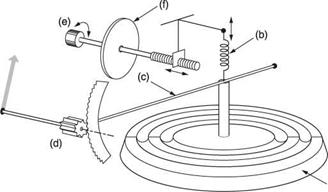

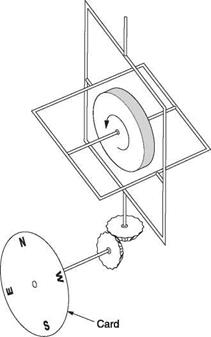

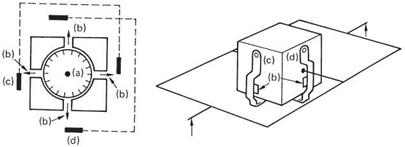

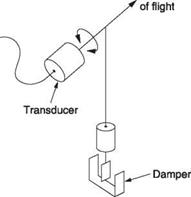

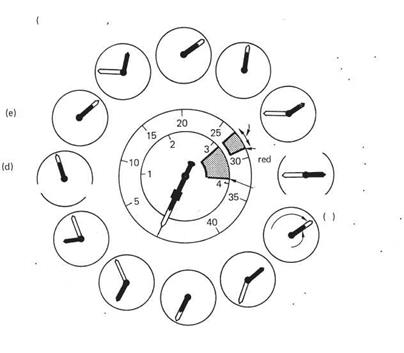

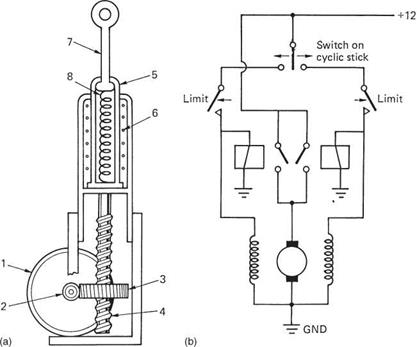

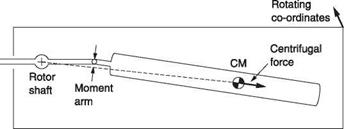

The principle of the governor goes back to the first steam engines. In the centrifugal governor shown in Figure 6.3 a pair of weights are attached to a shaft driven by the engine such that they will fly out as speed increases. This is arranged to reduce the power so a set speed cannot be exceeded. The speed is set by a change to the spring tension applied to the linkage. If the spring tension is increased this tends to increase the power and the weights have to spin faster before they can produce enough force to reduce power.

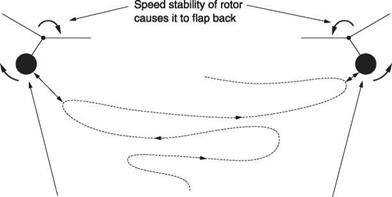

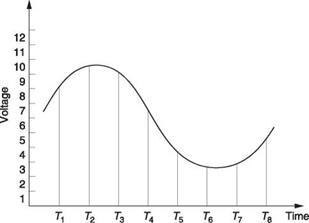

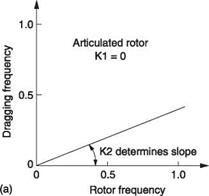

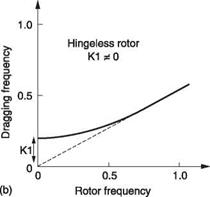

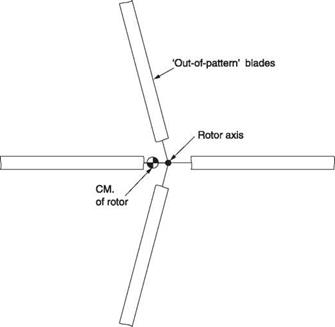

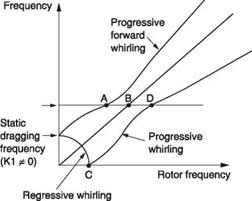

In practice the engine revs will not be held perfectly stable because if more power is demanded the power control must be operated to provide it. The engine RPM must reduce slightly in order to create an error. Figure 6.4(a) shows that this is known as static droop. Static droop can be reduced by increasing the amount of power control movement for a given speed error. This effectively changes the gain applied to the speed

difference of the system. Increasing the gain will allow tighter control of speed but it also increases the chance that the system will become unstable so that it swings between too fast and too slow without stabilizing. A better solution is to combine governing and correlating systems so that there is both feedback and feedforward. Figure 6.4(b) shows how this is done. The power setting is determined by the sum of two signals. One of these is the feedforward signal from the collective lever. This provides approximately the right power setting. The second signal is the RRPM error feedback from the governor that slightly adapts the power setting to minimize the speed error. As most of the power setting is provided by the feedforward signal, the static droop will be minimal.

Piston engines are geared to the rotor and so run at near-constant RPM. The power delivered is changed with a change of torque and with a naturally aspirated engine this can be done instantly by adjusting the throttle or, in the case of a Diesel, changing

the amount of fuelling. This does not happen in a free turbine engine where only the power turbine is geared to the rotor. Instead, greater power will be supplied by an increase in the gas generator speed (N1) that delivers greater torque at the free turbine. N1 cannot increase immediately. It takes time for the spool to accelerate. As a result there will be a temporary loss of RRPM during the time taken to spool up. This is known as transient droop. Figure 6.4(c) shows transient droop following a step change in power demand. Turbocharged piston engines will also display transient droop as the turbocharger accelerates.

Transient droop may be reduced through sensing the collective lever velocity. During a landing, collective will be lowered and this will cause the gas generator to spool down. If the landing is to be rejected, the pilot will pull the collective lever up. A system sensing collective velocity will be able to start spooling up sooner than one which simply waits for the lever to come up to provide power demand.

If the collective lever is raised too far on a turbine machine, the result will be an overtorque condition as the governor maintains RRPM. However, on a piston-engine helicopter once the throttle is fully open, further application of collective will cause overpitching. Induced drag causes a reduction in RRPM. In a machine with a manual throttle the correct recovery from overpitching is to maintain full throttle and to reduce collective pitch momentarily to regain rotor speed. If such a machine were fitted with a correlator the act of lowering the collective pitch lever could reduce the throttle setting and delay the RRPM recovery. The operation of a governor would not be impaired because a reduction in RRPM would result in a large speed error that would fully open the throttle. In the optional governor system of the Robinson R-22 the throttle is controlled by a governor mechanism responding to RRPM. However, an additional system is fitted which prevents overpitching. If the throttle is wide open to recover RRPM but the rotor speed fails to respond, an additional servo motor reduces the collective pitch setting until the speed error has been reduced. The collective servo linkage is fitted with a slipping clutch so that in the case of a failure the pilot can override it. The first use of a mechanism to maintain rotor speed by lowering collective was by Flettner in the 282 Kolibri.

In practice a free turbine engine needs two governors, one for the gas generator spool and one for the power turbine. These will be part of the fuel control system. Either of them can limit the turbine fuelling to prevent overspeeding. The gas generator governor is used for starting, idling and shutdown, and is controlled by the throttle lever in the cockpit. For flight, the throttle lever is set to maximum so that gas generator RPM is no longer able to restrict fuelling. This results in acceleration of the gas generator spool and increased gas flow that brings the rotors up to flight RPM. The rotor speed is then controlled using the power turbine governor which limits fuelling as correct RRPM is reached.

The piston engine is now over 100 years old but modern designs still work in the same way as the machine built by von Otto.

Figure 6.5 shows a section through a typical horizontally opposed piston engine. The pistons slide to and fro inside the cylinders and they are joined to the rotating crankshaft by connecting rods. The connecting rods, generally abbreviated to con rods, must be able to swivel in the pistons, and this is the function of the gudgeon pin, which passes through the little end of the con rod. The other end of the con rod must have a larger bearing in it to fit around the strong crankpin. In the boxer engine the crankshaft

is constructed so that the pistons all move in and out simultaneously. The reaction due to accelerating the piston on one side is then balanced by that from the other side and vibration is reduced. The cylinders are not precisely opposite one another to give room for the crank web.

The large bearing in the connecting rod is called the big end. The aluminium pistons have slots fitted with rings which are springy metal strips. These press outwards against the cylinder wall and ensure a good pressure seal. In a piston engine four distinct stages are needed in the complete cycle, and in the four stroke or Otto cycle engine, the piston traverses the cylinder four times, which requires two revolutions of the crankshaft. The cylinder head is fitted with valves allowing fresh charge to enter the cylinder and burned charge, or exhaust, to leave. The valves are operated by a camshaft fitted above the crankshaft. This carries a series of rounded bumps called lobes. As the camshaft turns, each lobe presses against the flat end of a small piston-like object known as a tappet. In the tappet there is a swivel joint that connects to the push rod. This travels in a tube up the outside of the cylinder to a rocker in the cylinder head that pushes the valve open. When the cam lobe retreats, the valve is closed by the valve springs, which also push back the rocker, the pushrod and the tappet. When the valve is closed there must be a little slack in the pushrod, known as valve clearance, so that the whole spring pressure is keeping the valve shut.

Since the full four strokes require two crankshaft revolutions, the camshaft is driven through a 2: 1 reduction gear so the sequence of valve openings resulting from one camshaft rotation is spread over the two crankshaft revolutions. On the intake stroke, the inlet valve is opened and charge is drawn into the cylinder. On the compression stroke both valves are closed and the charge is squeezed into the remaining space above the piston. On the power stroke, pairs of spark plugs ignite the charge, and it burns and expands, driving down the piston and turning the crankshaft. On the exhaust stroke, the exhaust valve opens and the piston pushes out the spent charge. The cycle then repeats.

In practice momentum of the gases means that the valves operate at a slightly different time than this simple explanation would indicate. Figure 6.6 shows a typical valvetiming diagram. During the induction stroke the charge entering through the inlet manifold is travelling at high speed and cannot stop easily. The inlet valve is left open until after bottom dead centre (BDC). Momentum will continue to force charge into the cylinder so that extra charge can be admitted allowing more power to be generated.

|

The exhaust valve opens before BDC so that the exhaust can start to accelerate out of the cylinder in time for the exhaust stroke. The exhaust gases leave at high speed, and at the end of the exhaust stroke the momentum of the gases will carry them onwards even when the cylinder is empty. This causes a reduction in pressure in the cylinder. The inlet valve is opened before the exhaust valve closes so that the momentum of the exhaust leaving will pull fresh charge in. This is known as valve overlap. Racing engines use camshafts having a lot of valve overlap to help charge transfer at high speed. This makes them very rough at lower speeds. Helicopter engines are required to have good throttle response over a limited RPM range rather than ultimate power, and will be fitted with milder camshafts.

The valve mechanism in early engines required an adjustment to take up slack in the pushrod as wear took place. A small clearance was left to allow the parts to expand without the valves being pushed open when they were supposed to be shut. If the valve clearance was excessive the valves would not open for as long, and power would be reduced. The mechanism would make a lot of noise. Tappet adjustment was frequently required to maintain performance.

In later engines a self-adjusting mechanism was devised. The tappet contains a small piston that drives the pushrod. Engine oil pressure is communicated to the tappet through a small drilling so that the piston will move until it has taken up the slack in

the valve train. When the camshaft opens the valve, the force is transmitted through the oil pressure. The drilling is too small to allow a significant amount of oil to be forced back out of the tappet. Hydraulic tappets are self-adjusting and the periodic maintenance is eliminated.

|

Ignition of the charge is achieved by the generation of a spark between a pair of electrodes in the cylinder head. A very high voltage is needed to break down the insulation of the compressed charge so that a spark can occur. The high voltages present in ignition systems cause stress to the components, and as a result the ignition system is probably the least reliable part of the engine. This is overcome in aircraft engines by having a completely duplicated ignition system. There are even two spark plugs per cylinder, one for each ignition system. This also allows a small increase in power because the charge is ignited in two places at once.

In cars, the high ignition voltage is generated by an induction coil driven by the electrical system. If the electrical supply is cut off the engine stops. This is not reliable enough for aircraft, and these use an alternative system that generates its own electricity directly from engine shaft power using a rotating magnet. This magneto-dynamic ignition unit is invariably known by the abbreviation of magneto. In a magneto system the engine will keep running even if the electrical system of the helicopter has totally failed. A pair of magnetos are fitted on the back of an aircraft engine, driven by the gear cluster that drives the camshaft and the oil and fuel pumps. When the aircraft engine is mounted backwards in a helicopter, the magnetos can be found adjacent to the cockpit firewall.

The principle of operation of the magneto is based on the same physics as electricity generation. When current flows through a coil of wire, it generates a magnetic field. The field can be amplified by winding the coil around a soft iron core. If the magnetic field passing through a coil is constant, there is no effect, but if the field changes, a voltage proportional to the rate of change of flux is induced. The two phenomena described above combine to give a coil the property of inductance. An inductor is a sort of magnetic flywheel. A mechanical flywheel stores kinetic energy proportional to the square of the speed. An inductor stores magnetic energy proportional to the square of the current. In the same way that a flywheel resists changes of speed, an inductor resists changes of current.

Imagine an inductor with a current flowing through it. If some external resistance attempts to reduce the current, the magnetic flux in the coil is reduced. The falling flux induces a voltage in the coil that attempts to increase the current. On the other hand if something attempts to increase the current, the magnetic flux will increase, and the change of flux in the opposite direction will induce a voltage that opposes the current. As a result the inductor tries to keep the current passing through constant.

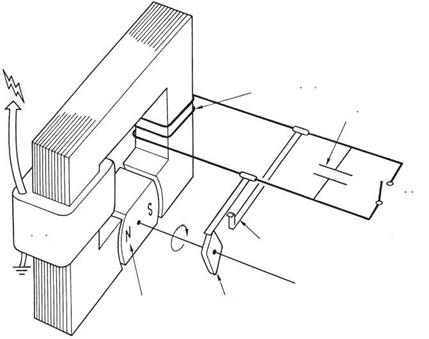

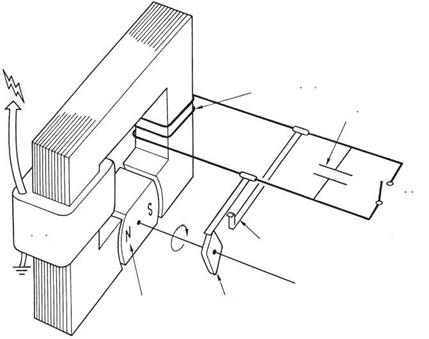

Figure 6.7 shows the construction of a magneto. The input shaft turns at camshaft speed and carries a powerful permanent magnet. As the magnet turns its magnetic field passes through stationary poles in alternate directions. Around one of the poles is a winding of thick copper wire. The ends of this coil can be shorted out by a pair of contacts, known as points, operated by a cam on the input shaft. A capacitor is fitted across the points that are closed when the magnet flux in the stationary pole is changing from one direction to the other. The changing flux induces a voltage in the coil, but the coil is shorted out so there is very little resistance. The coil builds up a high current at a rate determined by the inductance.

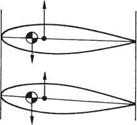

Magnet

Magnet

Fig. 6.7 eto generates its own electricity and so is potentially more reliable than an ignition system

using the aircraft’s electrical supply.

When maximum current is reached, the cam opens the contacts. The inductance attempts to keep the current flowing, but it cannot pass the open points. The only place the current can go is through the capacitor. As the capacitor charges up, the current reduces. This reduces the inductor flux and increases the induced voltage. When the current finally stops flowing, the capacitor is charged to a high voltage. The magnetic energy has been exchanged for electrical energy stored in the capacitor. The voltage on the capacitor now reverses the current, which builds up in the inductance. The current keeps flowing after the capacitor voltage has fallen to zero and charges the capacitor up in the reverse direction. The inductor and capacitor form a resonant circuit where the energy repeatedly exchanges between the inductor and the capacitor and an alternating current flows in the windings. The same effect is achieved mechanically in a tuning fork.

As the capacitor is quite small, the frequency of oscillation is quite high, and the rate at which the current changes is also high. Thus a high rate of flux change is achieved in the inductor. A secondary coil consisting of many turns of fine wire is wound on top of the first coil. The rapidly alternating flux induces a very high alternating voltage in the secondary coil, and this results in a rapid succession of sparks at the plug electrodes. The sparks continue until the magnetic energy is dissipated. In a multi-cylinder engine, this high tension (HT) current is directed to the appropriate cylinder by a rotary switch called a distributor on the end of the shaft. There is no mechanical contact in the distributor; the metal parts come close enough for the HT to jump across the gap, so in fact there are two sparks in series, one at the plug and one at the distributor.

The capacitor is a vital part of the system, because without it the current would have nowhere to go when the points open, and most of the magnetic energy would be dissipated in a spark at the points, which would then be rapidly eroded away. The spark in the cylinder would then be very weak. This can happen if the capacitor becomes disconnected or fails open circuit. If the capacitor fails short circuit the points are bypassed, and no spark will be produced at all. This type of failure is rare.

The HT wiring to the spark plugs needs to be well insulated so that the HT does not jump to the nearest piece of metal instead of going to the plug. At high altitude the reduced air pressure reduces the insulating ability of the air, and as a result the ignition leads must have somewhat better insulation than those found in cars. Part of the pre-flight check is an inspection of the condition of the HT leads. Needless to say they should not be touched when the engine is running.

Whilst the magneto has the advantage that it is completely independent of the helicopter’s electrical system, it does suffer from one disadvantage. When starting, the engine speed is low, and the rate of change of flux in the magneto will be correspondingly low and a poor spark results. One solution to this problem is a device known as an impulse coupling which is basically a torsion spring in the magneto drive shaft. The presence of the permanent magnet makes the torque needed to rotate the magneto vary with the angle of rotation. This can easily be demonstrated by attempting to turn a bicycle dynamo by hand. At starting speed, when the torque is large, the spring in the impulse coupling is wound up as the magneto lags behind the shaft. As the torque falls, the spring tension is released, and the magneto is temporarily turned faster than the shaft. This allows a larger spark to be generated. A further use of the impulse coupling is that the lag delays the time at which the spark is generated. Under normal conditions, the spark is supplied a little before top dead centre (TDC) in order to allow the charge time to start burning before the power stroke. At low starting RPM, the advanced spark might cause the engine to kick back, or fire during the compression stroke. The delay of the impulse coupling prevents this happening. At normal operating speed the torsion spring does not have time to twist and the magneto runs at constant speed with the correct timing.

Dual ignition systems are provided to increase the reliability of the engine. This reliability increase is only present if both ignition systems are working properly. Part of the pre-flight check is to test the ignition system. This is done using the ignition switch. As the magneto is self-contained, the only way it can be switched off is by shorting out the points. The ignition switch is connected across the points and the magneto is switched off by closing the ignition switch contacts. This is a safer approach since a broken wire from the ignition switch will not stop the engine. The ignition switch is constructed so that either or both magnetos can be switched on. In aircraft the ignition switch may have a further position to operate the starter, but this is not used in helicopters. Instead the starter button is fitted on the end of the collective lever where it may be operated by the pilot without letting go of the controls.

When the engine is warm, the dual ignition may be tested. At a specified RPM, the ignition switch is turned from ‘both’ to ‘left’. This disables the right magneto. The result should be a slight reduction in RPM, known as a magneto drop, because only one spark is being generated per cylinder. The drop is normally that which is measured after 5 seconds running on one magneto. The engine is run on both systems again for a short time to clear any fouling which may have built up on the plugs whilst they were out of use. The switch is then set to ‘right’, when an identical drop should be obtained. If the drops are grossly different or do not occur, there is a problem which must be rectified before flight.

To take an example, if on switching from ‘both’ to ‘left’ there is no drop, either the right magneto was not working or it has not been switched off due to a broken wire. Switching to ‘right’ will show which. If the engine cuts, the right magneto is inoperative. If a drop is obtained, the right magneto is permanently on due to a wiring fault. This can be proved by switching off the ignition. If the engine continues to run, the wire to the ignition switch is broken. The engine can be stopped by the idle cut-off as normal.

If the drops are not identical, one ignition system is working better than the other for some reason. If only an RPM loss is noted, the different drop could be due to a timing difference between the magnetos. If one magneto gives a larger drop and a misfire, consideration should be given to the possibility of a failed spark plug or capacitor or a fractured HT lead.

The cylinders are numbered from what would be the front in an aircraft, which in a helicopter corresponds to being numbered away from the drive pulley. In a Lycoming engine mounted back to front in a helicopter, the odd numbered cylinders are on the port side. The sequence of power strokes is designed to reduce torsional stress in the crankshaft by firing cylinder pairs alternately. This gives the firing order of 1-3-2-4.

|

The starter is basically a powerful electric motor used to turn the engine. A reduction gearing system is needed so that the starter can develop enough torque to overcome the engine compression. A small pinion on the starter engages with a large ring gear on the engine flywheel. The gears are only engaged during starting. This can be done by a helical thread mechanism that screws the pinion along the motor shaft or by a solenoid that slides it. In the latter type a one-way clutch prevents the engine driving the starter. Recently geared starter motors have become available. These have a high speed electric motor and a reduction gearbox and are lighter than conventional starters and consume less current. The weight saving may be compounded because they allow a smaller battery and thinner wiring to be used.

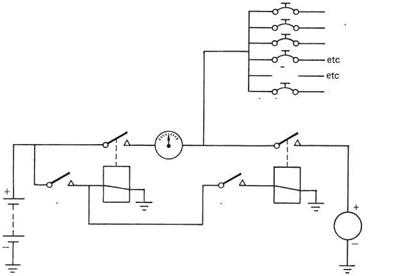

The motor must be quite powerful, and it will require a current of several hundred amperes to operate it. In order to minimize power loss in the cables, these run direct from the battery to the motor. This current is beyond the capability of a switch, and a relay is used. The starter button on the collective lever switches a small current through a solenoid coil, and this attracts the solenoid armature, sliding the starter gear into engagement with the flywheel and pulling the main motor contacts closed. Normally the starter motor gear is driven through a one-way clutch so that it can run at high speed when the engine fires without damaging the starter motor. A warning light is fitted which should go out if the starter button is released. If it does not the starter may still be engaged.

If the starter fails to operate, this could indicate a faulty solenoid. It is generally possible to hear the solenoid operating. If the solenoid chatters or vibrates this indicates a loose battery connection or a discharged battery.

The starter motor dissipates a lot of heat when starting, and if the engine does not start promptly because it is flooded or vapour locked, prolonged cranking will flatten the battery and overheat the starter motor. It is better to allow a cooling period between starting attempts than to burn out the starter motor. The starter motor should never be operated when the engine is running as engaging the starter pinion with the fast turning gear on the flywheel could remove teeth. The engine must be allowed to come to a complete halt before making a further starting attempt.

The oil system is responsible for lubrication and cooling of the moving parts of the engine. Heavy forces are involved in the connecting rods and crankshaft bearings, and if metal-to-metal contact took place the life of the parts would be very short. Oil possesses viscosity, which is a resistance to flow. If viscous oil is pumped between two surfaces it can carry a load without them touching because the viscosity resists the oil being squeezed out. The relative movement of the surfaces causes shearing of the oil. Shearing a viscous liquid develops heat, and this heat load adds to the heat picked up where the oil is used to cool parts of the engine. An oil cooler is necessary to control the oil temperature.

The oil system is responsible for lubrication and cooling of the moving parts of the engine. Heavy forces are involved in the connecting rods and crankshaft bearings, and if metal-to-metal contact took place the life of the parts would be very short. Oil possesses viscosity, which is a resistance to flow. If viscous oil is pumped between two surfaces it can carry a load without them touching because the viscosity resists the oil being squeezed out. The relative movement of the surfaces causes shearing of the oil. Shearing a viscous liquid develops heat, and this heat load adds to the heat picked up where the oil is used to cool parts of the engine. An oil cooler is necessary to control the oil temperature.

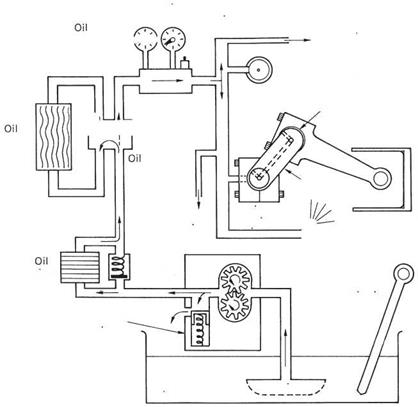

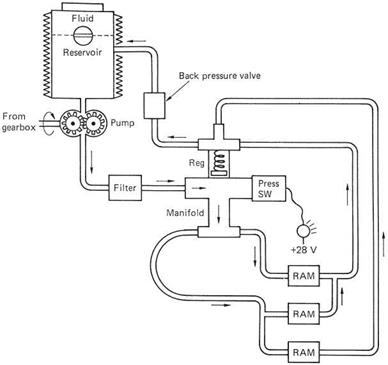

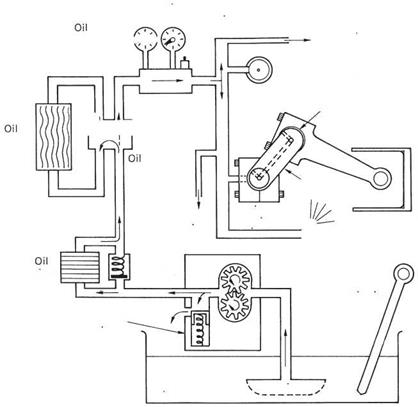

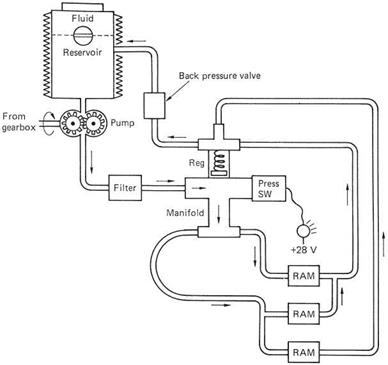

Figure 6.8 shows a typical engine oil system. Oil is held in the sump below the engine. The sump contains a filler neck whose cap holds a dipstick so the oil level can be checked. This should be done before flight. Oil is drawn from the sump through a strainer to prevent particles of dirt from damaging the pump. The pump may consist of a pair of meshing gears driven from the camshaft/magneto drive cluster at the rear of the engine. The capacity of the pump exceeds the requirements of the engine, and surplus oil is returned to the sump by a spring-loaded relief valve that opens when the correct

Oil pressure gauge and switch

temperature b-o-l

gauge

Camshaft

thermostatic

Crank

Dipstick

Pressure relief valve

Oil sump

Fig. 6.8 Lubrication system for a typical piston engine. See text for details.

oil pressure is reached. The oil then passes through a filter that removes microscopic particles of metal due to engine wear and combustion products that have found their way past the piston rings into the oil. The filter needs to be replaced periodically. If the filter becomes clogged, a spring-loaded valve opens allowing oil to bypass the filter.

The oil next passes to the oil cooler. This is a small heat exchanger that is often fitted in the engine cooling baffles so that it gets a cold air feed from the engine driven fan. The cooler is bypassed by a thermostatic valve that is open at low temperatures to allow the oil to warm up quickly. The valve can also be forced open by oil pressure if the cooler blocks up. At the outlet of the cooler the oil is ready to be fed to the engine. At this point the oil pressure and temperature are monitored and displayed on gauges in the cockpit. Some of the oil is fed to the main crankshaft bearings. The crankshaft is hollow and oil is pumped in from the main bearings and flows to lubricate the big ends. The connecting rods may also be hollow and oil carries on up the rods to lubricate the little end. An oil jet is drilled in the top of the connecting rod to spray oil on the piston for cooling and to lubricate the cylinder wall. Oil is also supplied to the camshaft bearings and the valve mechanism as well as to the gear train driving the camshaft and the magnetos. The oil will eventually fall back into the sump.

The engine oil has a finite life primarily because it builds up an increasing load of acids, which are by-products of combustion, and water from condensation. Oil is characterized by its viscosity. Viscosity is measured by the time taken in seconds for a standard quantity of oil to flow through an orifice standardized by the Society of Automotive Engineers (SAE) at a standard temperature. Oil may also be classified by a commercial aviation number that is twice the SAE number.

The viscosity of oil falls with increasing temperature. So-called multi-grade oils have a smaller viscosity loss with temperature. The correct viscosity of oil is essential and it must be used at the correct temperature. If the oil is too viscous or used at too low a temperature, it may not flow readily to all the necessary parts of the engine. If the oil is too thin or used at too great a temperature, it may be squeezed from bearings and permit contact. The engine oil must be warmed up before flight so that correct lubrication is achieved when full power is demanded.

The flight manual will specify the viscosity of oil that must be used in temperate conditions. A mandatory placard on the machine adjacent to the filler will state the viscosity needed. If the machine is consistently operated at elevated ambient temperatures, it may not be possible to keep the oil down to the required temperature. In this case thicker oil will be used which will thin down to the right viscosity at the elevated temperature. In a similar way if the machine is to be used in cold conditions the oil may run too cold and thinner oil will be specified to get the right viscosity at a lower temperature. It is important that the oil level is checked regularly and kept topped up with the same type of oil. Oil grades should not be mixed and it is better not to mix brands. Oils contain a host of additives to improve performance and sometimes the additives in one kind of oil react with those in another. Turbine engines need oil with different additives and viscosity. Turbine oil cannot be used in piston engines.

The oil pressure and temperature gauges tell a great deal about the health and working conditions of the engine and should be monitored regularly as part of the pre-flight check and whilst airborne. On starting the engine, it may take some time for oil pressure to be established as the oil is cold and thick and the pump has difficulty dragging it from the sump. Expect the delay to be longer in cold conditions. Generally if oil pressure has not established in 30 seconds the engine should be shut down and the cause investigated.

When cold the oil resists flowing through the engine and once pressure is established the pump has no difficulty supplying enough pressure. Paradoxically, once the pressure has established, it may become excessive in cold conditions or if using straight

(non-multi-grade) oil in a new engine. In this case the engine revs must be kept to a minimum after starting until the oil has warmed up. Another cause of excessive oil pressure at idle is if the relief valve has stuck. In any case of excess pressure, engine revs must not be increased as a further increase in pressure could burst the oil filter or the cooler.

In a hot engine the oil flows more freely and worn bearings will increase the oil flow. At idle speed the oil pump may not be able to meet the flow demand and the pressure will fall. Thus low oil pressure with hot idle may indicate bearing wear.

After a cold start, the engine should be run on the ground until the oil temperature has reached a minimum level for flight. If it takes an excessive time for this temperature to be reached the thermostatic valve in the oil cooler could be stuck and making the cooler work continuously.

Sudden and total loss of oil pressure in flight is rare and will be due to a mechanical failure such as a sheared pump drive or a burst pipe. The engine will be destroyed unless it is shut down immediately. If a suitable landing site is available, the engine should be stopped and an autorotating landing will be needed. A conscious decision to autorotate is safer than trying to land using power because without oil the engine could sieze up without warning and this might occur in the avoid curve. If no suitable forced landing site is near, it will be necessary to sacrifice the engine in order to attempt to fly to safety. Flying at minimum power speed will buy time.

A more likely fault situation in flight is where the oil temperature slowly rises and the oil pressure slowly falls. This is an indication of oil loss due to a leak or oil being burned in the cylinders. A landing should be made promptly so that an investigation can be made.

When assessing the oil pressure and temperature gauges, the stress the machine has been under should be considered. Following a lengthy climb at maximum all up weight (MAUW) one might expect hot engine oil. The stress on the machine would be reflected in elevated transmission oil temperature and cylinder head temperature. If all of these readings are high, the machine is being driven hard and should be flown in a way that will reduce the power requirements.

On landing the engine should be run at idle for a short while in order to cool it. If this is not done oil inside the engine will be exposed to heat that it cannot carry away and the oil could be carbonized and lose effectiveness. This is known as heat soak.

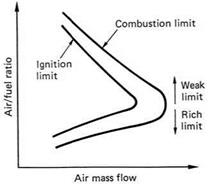

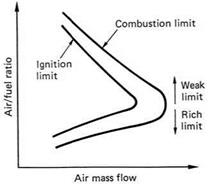

Engines produce power by burning charge. The purpose of the carburettor is to mix air and fuel to create charge. Charge will burn over the following range of fuel/air mixes. A ratio of 1 part fuel to 8 parts air is called a rich mixture, and not all the fuel will be burned. A ratio of 1:20 is called a lean mixture and not all of the oxygen will be burned. A ratio of about 1:12 is called a stoichiometric ratio as there is just enough fuel to combine with all the oxygen.

Clearly a chemically accurate ratio will give the most power and a lean mixture will give the best fuel economy. Unfortunately it is not possible to take full advantage of this because of a number of practical considerations. At high power the engine temperature cannot be kept at a safe level unless a rich mixture is used. The surplus fuel absorbs heat by evaporation.

The four-stroke engine compresses the charge before combustion to increase the power output. The greater the compression ratio, the more power can be released. When charge is ignited it should proceed to burn smoothly as a flame front travelling

away from the spark plug. Unfortunately when charge is compressed the temperature will be raised and it can detonate instantly when ignited. This causes a rapid pressure step that creates shock waves travelling through the engine. A metallic ringing noise called ‘pinking’ or knock can be heard. If sustained, engine damage will result.

The ability of a fuel to resist detonation must be matched to the compression ratio of the engine it will be used in. The detonation resistance of fuel is measured in a special variable compression test engine. The fuel under test is used to drive the engine and the compression is increased until detonation commences. The engine is then run on iso-octane, a relatively detonation resistant hydrocarbon, and this is steadily diluted with heptane, a detonation prone fuel, until detonation commences. The percentage of octane at which this takes place is the octane number of the fuel. Since the test was devised, more detonation resistant fuels have been developed, and the scale has been extended above 100 by extrapolation.

Using fuel of inadequate octane number for the engine causes damage through detonation. The machine carries mandatory placards adjacent to the fuel fillers stating the octane number of the fuel that must be used.

A rich mixture helps to prevent detonation by reducing the temperature increase during compression. Fuels are often specified by two octane numbers; the second is for a rich mixture. For example, many piston helicopters burn 100/130 LL fuel. At normal mixtures this is 100 octane, but at full rich mixture it is 130 octane. LL stands for low lead. In the 1920s it was discovered that the addition of tetra-ethyl lead to fuel increased the octane number. Decades later it was proved that the resultant lead pollution was slowing the rate of brain development of children living near busy roads and less damaging alternatives have had to be found.

Whilst fuel of inadequate octane rating causes damage, occasional use of higher octane fuel is acceptable. Prolonged use of high octane fuel may result in spark plugs being fouled by the octane-boosting additives. No power increase will be observed because the power output is determined by the engine design, particularly the compression ratio.

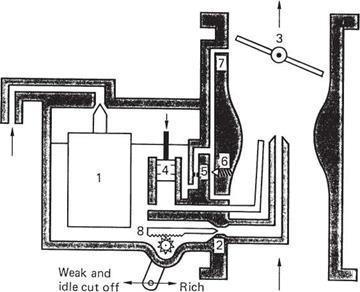

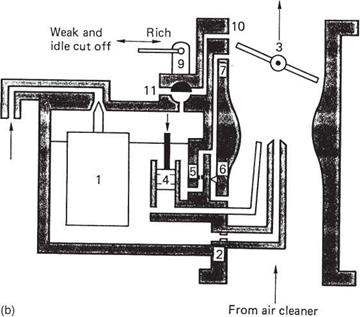

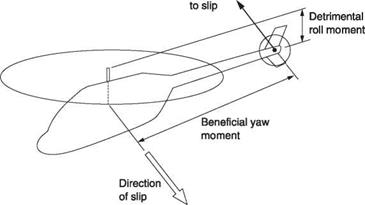

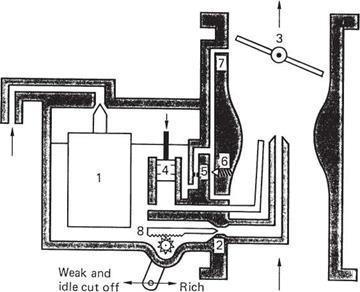

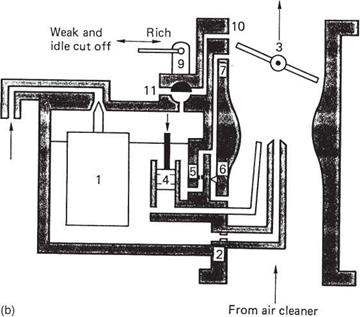

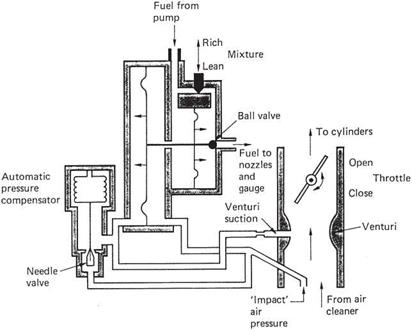

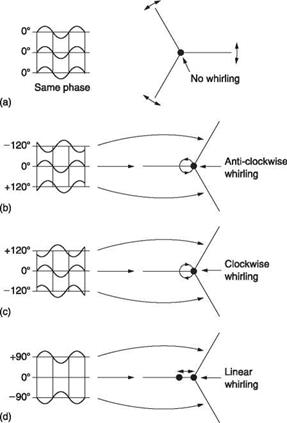

The carburettor has to mix the air and fuel in the chosen proportion. Figure 6.9 shows that it is a fairly simple device. Engine power is controlled by throttle (3): a disc that pivots in the intake tract. With the throttle wide open, the pressure in the inlet manifold will be nearly atmospheric, whereas with the throttle closed down to the idle position, the manifold pressure will be near zero. Manifold pressure is displayed on a gauge in the cockpit as it indicates the proportion of maximum power the engine is producing. The pilot needs to know how much reserve power is necessary before committing himself to a manoeuvre needing higher power: a procedure called a power check.

The result of throttling the engine is to reduce the flow of air through the carburettor. The fuel flow must remain proportional to the mass flow. This is done by the creation of a small constriction or venturi in the inlet tract. The air must go faster through the smaller cross-section. This increases the dynamic pressure of the air. As the static and dynamic pressures sum to a constant, the static pressure must reduce, as described by Bernoulli’s theory. The reduction in static pressure causes a pressure difference across the fuel in the carburettor body making it flow through a metering orifice or jet (2) and mix with the air. Clearly the depth of fuel could affect the pressure and the carburettor has a float valve (1) that admits fuel as it is used to prevent the level falling.

The system is self-balancing, because greater airflow causes greater suction at the venturi and increases the fuel flow. If the throttle is opened suddenly, the fuel inertia prevents a rapid increase in fuel delivery and the mixture will weaken momentarily. Weakening is prevented by the action of a small pump (4) that produces a jet of fuel when the throttle is opened quickly.

|

To inlet valves

(a)

From air cleaner

|

|

|

To inlet valves

Fig. 6.9 ettor is a simple device which uses a venturi to create a pressure drop that will suck fuel

from a jet. The jet may be variable (a) for mixture control, or this may be done by air bleed changing the pressure exerted on the fuel (b).

|

|

When the engine is at idle, the throttle will nearly be closed. The minimum throttle opening is set by throttle stop screw that prevents the engine inadvertently being stopped. With the throttle closed the airflow through the venturi is very small and insufficient to draw fuel. As the throttle disc reaches the closed position it admits low manifold pressure to a drilling in the side of the tract. This draws fuel from the float chamber through the idle jet (5), and air from the idle mixture screw (6). In effect a miniature carburettor is created to handle the small charge flow at idle.

As altitude increases, the air density falls but the fuel density doesn’t. The carburettor tends to produce a richer mixture than necessary. This is overcome by fitting a mixture control. There are two ways of controlling the mixture. In the first, shown in Figure 6.9(a), a needle valve (8) is placed in series with the main jet and changes the resistance to fuel flow. Placing the mixture control to idle cut-off stops the fuel flow altogether and stops the engine. In the second method, shown in Figure 6.9(b), low pressure from the inlet manifold is applied to the float chamber by a valve (9) to oppose the venturi suction and reduce the fuel flow. Idle cut-off is achieved by allowing full manifold pressure into the float chamber. There is no resultant pressure across the fuel and flow ceases.

The carburettor is a simple device but it does suffer from one major problem. The evaporation of fuel requires heat, and in the absence of any other source the heat is taken from the incoming air and the body of the carburettor. In humid conditions this can lead to the formation of ice in the carburettor venturi. The rapid flow around the edge of a nearly closed throttle and subsequent expansion into the low pressure in the manifold duplicates the mechanism of the domestic refrigerator and can cause throttle icing. This is particularly dangerous because at low power on a descent the ice build-up will not be noticed. When full power is required to arrest the descent it will not be available. The engine will artificially be throttled by ice and the mixture will be unpredictable.

The traditional approach to icing is to supply hot air to the carburettor intake. This is conveniently obtained by drawing air over the exhaust system. Unfortunately hot air is less dense and reduces engine power so it cannot be used all the time. The pilot is therefore provided with a control to select the carburettor heat. If there is the slightest suspicion of icing, full heat should be applied. If engine smoothness and power improve, there was icing. It may be necessary to apply heat periodically or continuously to control icing. If power reduces, there was no ice and the engine is running on air that is too hot.

Heat control requires a disciplined approach because the effects of an incorrect decision may not be evident until it is too late. Heat should be used for descents, but the prolonged use of heat on the ground is to be avoided if the hot air is not filtered. Some machines, such as the Robinson R-22, have a carburettor temperature gauge which is useful for deciding if heat is necessary. Air temperature has less effect on the probability of icing than does humidity. Carburettor heat has another problem which is that it affects interpretation of the manifold pressure gauge. This will be considered in section 6.14.

In comparison with modern automotive practice, in which electronic fuel injection is used almost exclusively, the aviation carburettor is a museum piece.

In a fuel injected engine there is no carburettor. The fuel is sprayed into the inlet manifold just before the inlet valve by a fuel nozzle. There is one nozzle per cylinder. The use of fuel injection has a number of advantages. Fuel vaporizing takes place in

a hot part of the engine where icing cannot occur. A fuel injected helicopter needs no hot air system and full power is always available with a corresponding increase in safety. Throttle response is instant. The flow measuring venturi restricts airflow much less than a carburettor, and maximum power is increased.

There are two types of fuel injection system. In mechanical systems, the fuel delivery is continuous and is determined by the fuel pressure in the fuel manifold (also known as the fuel distributor or flow divider). Fuel manifold pressure is displayed on a gauge in the cockpit, often combined with the inlet manifold pressure gauge. In electronic systems, the fuel delivery is controlled by a solenoid valve, one incorporated in each nozzle. In this case the fuel pressure is held constant relative to manifold pressure and the amount of fuel delivered is determined by the period of the pulses that operate the solenoids.

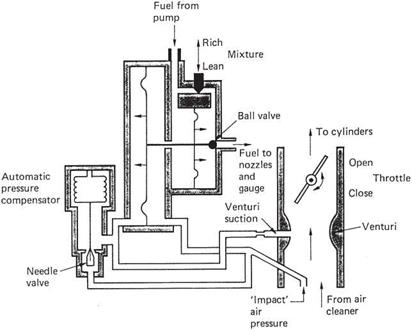

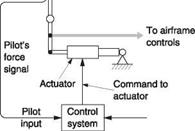

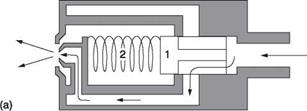

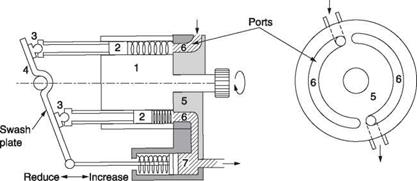

The engine power is controlled as usual by a throttle disc in the inlet duct. In a mechanical system, a small venturi is created in the duct and the suction created is a function of inlet airflow. The fuel pressure is made proportional to the venturi suction in the fuel control unit shown in Figure 6.10(a). The pilot’s mixture control changes the balance in the fuel control unit and the idle cut-off function stops all fuel flow.

The only real drawback of mechanical fuel injected engines is that hot starting can be difficult because residual engine heat vaporizes the fuel in the pipes leading to the nozzles. The solution is to purge the pipes and cool them with fresh fuel by running the boost pump for a few seconds with the throttle ‘cracked’ (partially open). The surplus fuel will flow into the inlet manifold and must be purged by operating the starter with the ignition off and the throttle wide. The throttle is then returned to idle, ignition is switched on and the starter operated again. Once the engine is running the boost pump is switched on again as a flight backup for the mechanical pump.

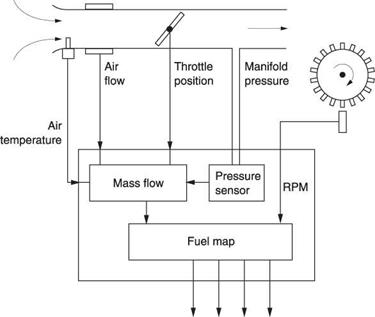

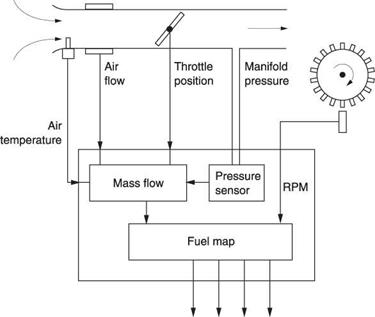

In electronic systems, a signal processor computes the correct amount of fuel to inject. It does this based on the mass flow of air into the engine. Figure 6.10(b) shows that engine RPM is measured by sensing ignition pulses or with a sensor adjacent to a toothed wheel. In the inlet tract, the air mass flow may be measured by a hot-wire sensor. Alternatively the manifold pressure may be measured. The air temperature is also measured to compensate the computation. As a result the mixture is always correct and no human intervention is required. In automotive applications, there is only one processor. This represents a single point of failure not acceptable in aviation. However, it is quite possible to provide one processor per cylinder each having its own sensors. It is also necessary to provide electrical power to the fuel injection system even if the main electrical power system fails. This is easily done using power-generation windings in the magnetos as is the practice in motorcycles.

Whilst the fine nozzles of injection systems are more prone to blockage than a carburettor, with proper filter and fuel management this is not an issue.

The power a piston engine can develop is a function of the charge burned on each power stroke. Clearly a greater charge can be obtained by using a larger engine, but this will be heavier, negating some of the increase in power. A more efficient way of increasing the power is to get more charge into a given engine.

In a naturally aspirated engine, when the piston goes down on the intake stroke, charge is pushed into the cylinder by atmospheric pressure. The elements of the induction system such as the air cleaner, the venturi and the valve stems all impede the flow.

|

|

|

|

|

|

|

|

|

Fig. 6.10 (a) A mechanical fuel injection system virtually eliminates intake icing because most of the induction system contains only air. (b) In an electronic fuel injection system the mass flow is calculated to determine how much fuel to inject. This is controlled by the length of time for which the injector solenoids are energized.

|

|

|

Fig. 6.11 The turbocharger uses energy from the exhaust gases to increase the mass flow of the induction process. See text for details.

|

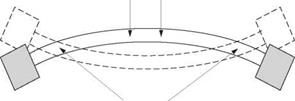

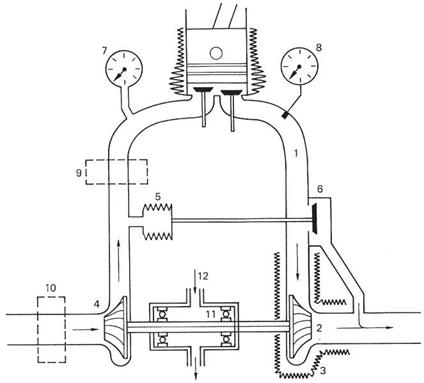

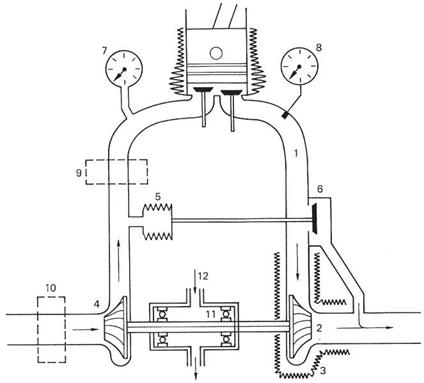

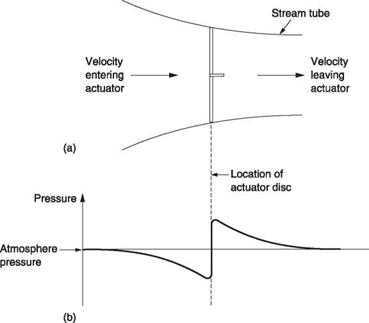

As altitude increases, atmospheric pressure reduces, so there is less to push the charge into the cylinder. The air density falls, so the mass of the charge is even further reduced. Without some help, the piston engine simply cannot breathe at altitude. Any device which forces more charge into the cylinder is a supercharger. These were originally mechanical pumps driven by the engine crankshaft. Later it was realized that the residual energy in the exhaust could be harnessed to drive the pump. This is the principle of the turbocharger shown in Figure 6.11.

Exhaust gases 1 pass through a turbine 2 before passing to the atmosphere. The presence of the turbine extracts energy from the exhaust gases, lowering the temperature and the pressure. The pressure drop needed to make the turbine work means that the pressure in the exhaust manifold, known as back-pressure, is higher than normal. Heat insulation 3 is usually needed around the exhaust turbine. The exhaust turbine drives a centrifugal compressor 4 that takes in air through the air cleaner 10 and forces it into the induction system. The boosted induction pressure is displayed on the boost gauge 7 and increases the charge entering the cylinder. Back-pressure in the exhaust prevents the charge blowing straight through during valve overlap.

The turbocharger is a simple device, but it may turn at over 20 000 RPM. The stresses due to this rotational speed are enormous, yet the material of the exhaust turbine also has to withstand the elevated exhaust temperature due to raising the power output.

Turbochargers only became economic when suitable materials were found which could withstand this kind of treatment for a reasonable lifespan.

A turbocharged engine without some form of control system could be dangerous. The more power the engine develops, the more turbocharging can be achieved, which develops even more power and so on. In practice this is prevented by a system controlling the induction pressure. The exhaust turbine may be bypassed by a valve known as a wastegate 6. If the induction pressure exceeds the design limits, the wastegate actuator 5 begins to operate to cut the power received by the exhaust turbine. At sea level the air is sufficiently dense that only a little exhaust energy is needed for charging and the wastegate will open relatively wide. As the machine climbs, air pressure and density fall, and the induction pressure tends to fall with it. The control system senses the fall in pressure and starts to close the wastegate. This diverts more of the exhaust through the turbine and drives the compressor faster until the pressure is brought back to the sea-level value. Clearly engine power is maintained with increasing altitude until the wastegate is completely closed, and after that, power will naturally fall off.

The compression process in the induction system raises the air temperature and reduces its density. A further power increase can be obtained by cooling the induction air between the turbocharger and the engine. This is done by an intercooler 9 that is a form of heat exchanger. These are uncommon on helicopters because of the extra complexity, but provided the weight is moderate the effects are beneficial.

It is sometimes claimed that turbocharged helicopter engines are less reliable because the turbo stresses the engine. Whilst this is true of racing car engines, where brute power for one race is the goal, the helicopter engine does not use the turbo so much to increase power as to maintain the same power under all conditions. This can only be a good thing.

From the pilot’s point of view the turbocharger does not cause any difficulty. In the cockpit the only change is that the figures on the manifold pressure gauge can go above sea-level pressure. There may be a boost pressure limit denoted by a red line. An overboost warning light is sometimes found. Turbocharged machines display transient droop. When more manifold pressure is called for, the wastegate has to close down to increase the turbo power, and it takes a finite time for the turbocharger RPM to increase.

Part of the pre-flight check is to inspect the turbocharger for mounting security (when it is cold!). The rotor bearing 11 needs a supply of oil from the engine oil system 12, and the small pipes should be checked for cracks or leaking unions.

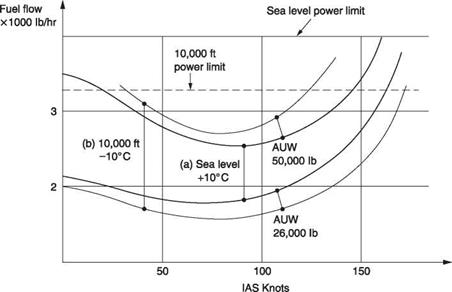

Power loss due to high altitude or air temperature has less effect on a turbocharged machine and when in-flight power checks are performed it will be seen that there is more reserve power than in a naturally aspirated machine.

In air-cooled gasoline engines, the cylinder head temperature (CHT) gauge is used after starting to determine if the engine is warm enough to run properly with the rotors engaged. After flight it is used to check that the engine has cooled down sufficiently to prevent heat soak when it is switched off. In flight CHT rises with the power the engine is asked to develop and if it reaches the red line on the gauge the power should be reduced. If the CHT reaches an unreasonable value for the applied load the possibility of an excessively weak mixture or a blockage or other defect in the cooling should be considered.

In water-cooled engines there will be a water temperature gauge which indicates the temperature of the water leaving the engine. Temperature should climb steadily after starting and level off at the designed temperature. This will often be above 100°C since the coolant is not actually water but a mixture of ethylene glycol and the system is also pressurized so that the boiling point is raised.

On turbocharged machines an exhaust gas temperature (EGT) gauge (8 in Figure 6.11) may be found. This will also rise with engine power and the gauge may be red-lined to protect the exhaust valves and the turbocharger.

The oil pressure gauge indicates the performance of the oil pump. If the pump can meet the flow demanded by the engine, the pressure will be normal. If it cannot, the pressure will fall. Low pressure could be due to a worn pump or bearings, but it could also be due to the oil being extremely hot so that it is thinner and runs through the engine faster than the pump can deliver it. The oil pressure and temperature gauges should be read together to form a meaningful picture.

The manifold pressure gauge and the fuel pressure gauge in a fuel injected gasoline engine both indicate the proportion of full power being developed and so the reserve power can be deduced. The fuel pressure indicator is also calibrated in fuel consumption rate so that the flying time can be calculated from the fuel load.

Manifold pressure or boost gauges are calibrated in absolute pressure, i. e. relative to a vacuum. In a naturally aspirated engine the manifold pressure cannot go above atmospheric and it is technically incorrect to refer to it as a boost gauge. In the presence of a turbocharger the manifold pressure can go above atmospheric and then the term boost gauge is correct. For a given induction air temperature, the boost pressure is proportional to the power the engine is developing. However, changing the air temperature changes the air density and so the mass flow, which really controls the power, will be different for a given boost pressure.

Consequently if carburettor heat is in use, the air entering the engine will be less dense and so less power will be developed for a given boost reading. If the engine is derated by setting an induction pressure limit, adhering to that limit with carburettor heat selected will result in unnecessarily limiting the available power. It is the actual power developed which determines the stress on the engine, not the induction pressure. With carburettor heat on, induction pressure can be increased by the correct amount to restore power without any risk of engine damage. It is important to know how much the induction pressure rises with carburettor heat for the same power. This can easily be established by hovering with and without carburettor heat.

With a traditional carburettor heat system, the pilot can be placed in a difficult situation. In the case of a fully loaded machine on a hot, humid day, full power will be required to hover. However, the landing approach will require the use of carburettor heat. At the end of the approach as the machine enters the hover, the textbooks explain that carburettor heat must be deselected. However, the textbooks do not explain how this is to be done. At the end of an approach and upon entering the hover, the pilot must manipulate the collective lever to arrest the descent and use the pedals to prevent yaw with the increased collective. He must also use the cyclic control to arrest forward speed. With both hands and both feet occupied, deselecting carburettor heat is difficult.

In the case of the Robinson R-22 there is a simple solution. In this machine the engine is derated by induction pressure limits to achieve reliability. The degree of derating is such that, even up to a few thousand feet above sea level, maximum rated power can be obtained even with full carburettor heat. Consequently under many real conditions the R-22 can be flown with hot air permanently selected. The boost gauge limit must be readjusted upwards. This is done by hovering under otherwise identical conditions with and without hot air to establish the percentage by which the induction pressure

limit must be increased to keep the power the same. Using this technique carburettor icing cannot occur, pilot workload is reduced and fuel economy is improved because feeding the engine with hot air reduces pumping loss. Given that there have been a number of fatalities in this machine owing to icing it is difficult to see why this solution has not been proposed earlier. The only circumstances under which hot air would be deselected would be where ambient air temperature is extremely high or for operation at high altitude. These conditions can easily be deduced from the flight manual.

|

The Diesel engine is a type of piston engine in which the induction process admits air only. There is no throttle and the maximum amount of air is admitted at all times. As only air is being compressed, a phenomenal compression ratio can be used without danger of detonation on the compression stroke. The high compression ratio which is maintained at all power levels, is responsible for the high efficiency of the Diesel engine. In the gasoline engine, when the throttle is partially closed, low manifold pressure opposes the motion of the piston on the induction stroke. The compression pressure falls, effectively reducing the compression ratio.

The compression raises the air temperature to such an extent that if fuel is forced into the cylinder it will burn immediately. The amount of power is controlled only by the amount of fuel injected. As combustion takes place with excess air, all of the fuel is burned, further raising efficiency. No ignition system is needed at all. Instead a device called an injection pump is required. This device produces the right amount of fuel at sufficient pressure to overcome the compression pressure and at the correct time. Fuel is fed into the cylinder by an injector. This is effectively a non-return valve that opposes the compression pressure in the cylinder. When the pressure from the injection pump has risen high enough, the injector admits the fuel in a conical spray pattern.

Diesel fuel is less volatile than gasoline and represents a reduced fire hazard. On injection, the fuel begins to burn instantly and this results in a rapid pressure rise. The Diesel engine needs to be robustly constructed to withstand the forces generated by the high compression ratio and the sudden pressure step. However, the Diesel has the advantage that the materials are not subject to such high temperatures. As it is thermally efficient, less heat is created in the engine and the exhaust is cooler, reducing stress on the exhaust valves. Water cooling is particularly advantageous with Diesels because the water jacket reduces noise and the reduced heat output allows the cooling system to be light.

As the Diesel engine induces only air and has no throttle, the danger of intake icing is insignificant and cold air will be supplied at all times for maximum power. The excess induction air may be used to sweep all combustion products out of the cylinder ready for the next cycle. This is called scavenging and in a four-stroke Diesel it is done by valve overlap. Some of the induction air follows the exhaust gases out of the cylinder. The exhaust valve is also cooled due to scavenging. This is especially easy in a turbocharged Diesel where turbo pressure assists the scavenge flow. Clearly scavenging cannot be used in the gasoline engine as it would result in unburned mixture entering the exhaust system.

The turbocharger works well in gasoline engines, but the extent to which power can be boosted is limited by the additional heat stress on the engine parts. As the Diesel produces less heat stress the degree to which it can be boosted by a turbocharger is higher. As the compressor in the turbocharger will increase the temperature of the induction air, a further increase in power can be obtained using an intercooler, which

is a heat exchanger designed to cool the air between the compressor outlet and the induction manifold. An alternative on water-cooled Diesel engines is a charge cooler which uses the circulating coolant to cool the air from the compressor.

The boost gauge reading is not proportional to power or engine stress in a Diesel engine since there is no throttle. If a turbocharger is fitted, the boost gauge will indicate that the correct turbo outlet pressure exists. A malfunctioning wastegate could cause excessive boost and an abnormally high gauge reading. In this case it would be necessary to fly at a lower power level to prevent engine damage.

In order to display the power level in a Diesel engine it is necessary to measure fuel flow. However, a torque meter could also be used as in turbine practice.

The two-stroke engine has some advantages for aviation, not least the saving in weight and complexity due to the elimination of some moving parts. Although power is produced on every piston downstroke, less of the stroke is used and so the increase in power is not as great as is commonly thought. However, the doubling in firing frequency for a given RPM allows vibration to be halved. This may result in transmission weight saving.

At the end of the power stroke, the exhaust gases have to be replaced by fresh charge at one and the same time. Thus effective scavenging is inherent in two-stroke engines. Some incoming charge goes out of the exhaust no matter what. The gasoline engine mixes fuel and air externally and so the scavenging process passes unburned fuel into the exhaust, doing no good to the fuel economy or the environment. A further problem with the gasoline two-stroke is that most designs use the crankcase as part of the induction system. When the piston comes down, the charge in the crankcase is compressed and the pressure is used to drive it into the cylinder. The presence of charge in the crankcase means that lubricating oil will be mixed with the charge, resulting in a smoky exhaust. The conventional gasoline two-stroke engine will eventually be outlawed because of these environmental concerns.

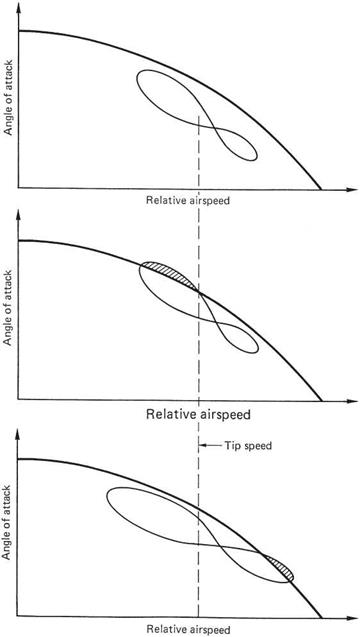

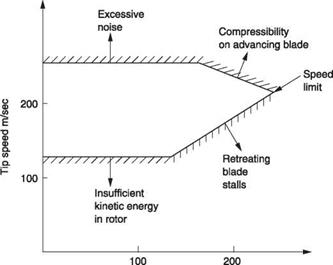

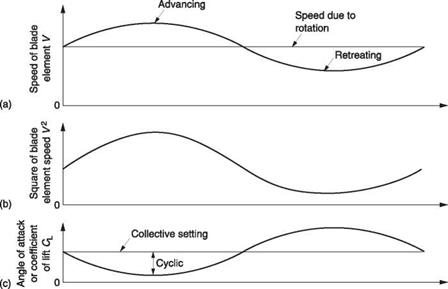

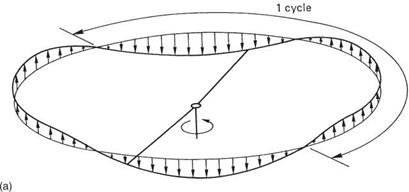

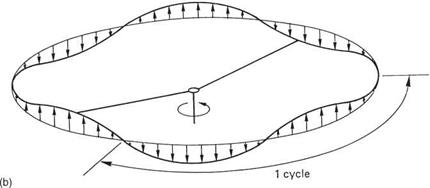

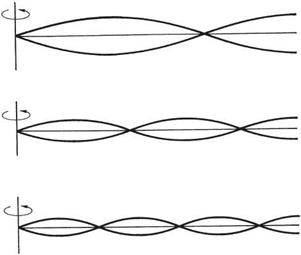

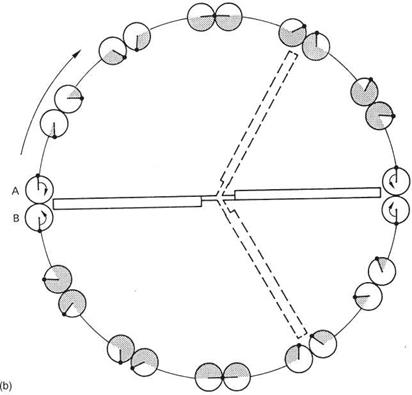

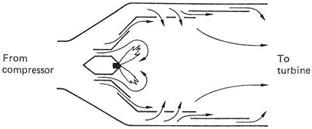

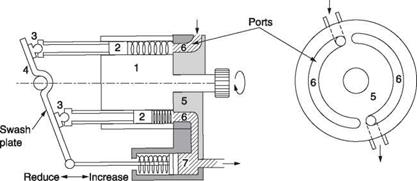

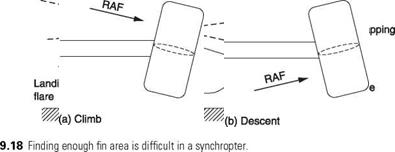

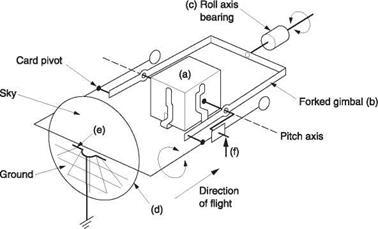

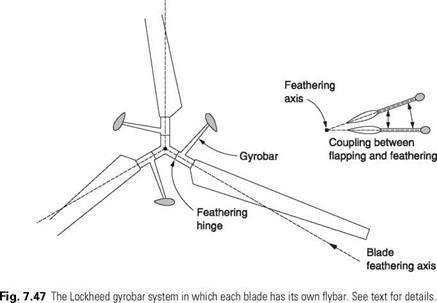

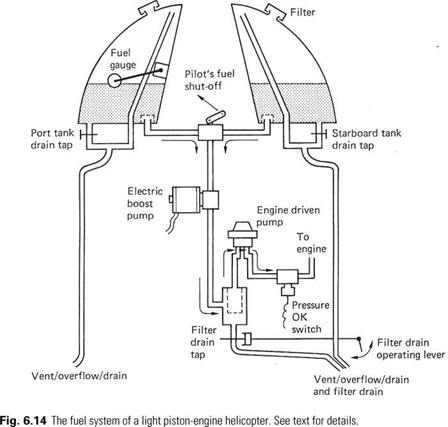

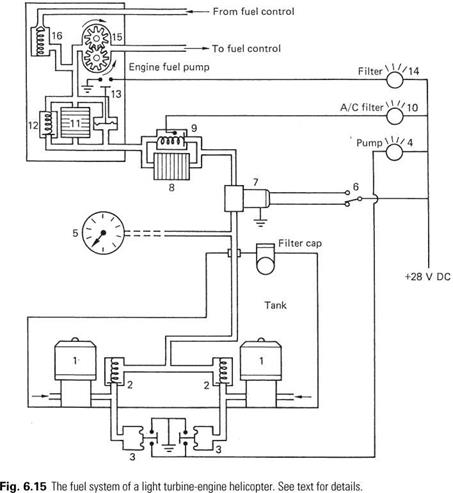

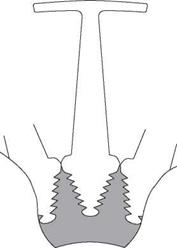

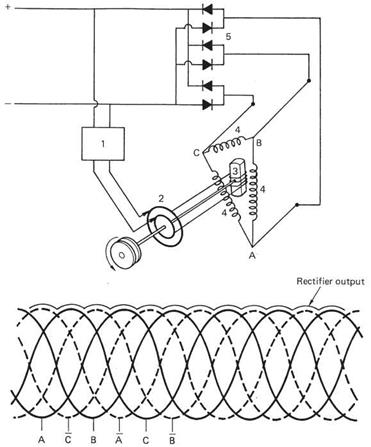

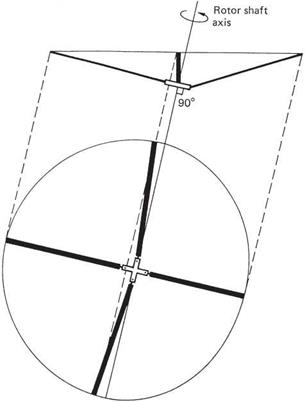

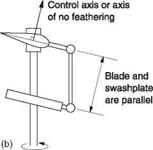

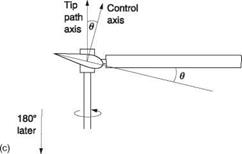

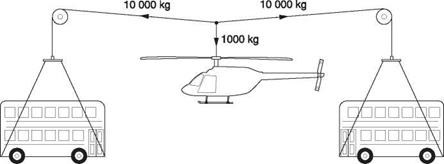

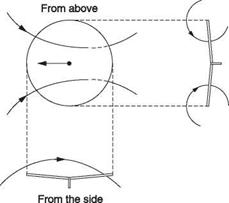

The two-stroke Diesel engine can overcome these problems because it admits air not charge. One approach is the uniflow two-stroke Diesel shown in Figure 6.12. This is mechanically somewhere between a four stroke and a two stroke as it still has a camshaft and valves. However, all of the valves are exhaust valves and a huge valve area can be used for efficient breathing.