Summary and Conclusion

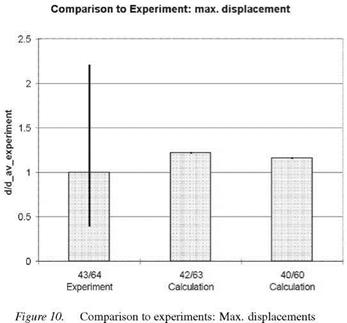

For this single stage turbine, the chosen unsteady Q3D approach and the applied 2-3 scaling give good results with respect to the overall blade displacement.

The scaling procedure of the CFD model causes only small differences in the unsteady pressure, especially for the 1st harmonic. Both numerical configurations are in good agreement to the unsteady pressure measurements, and the resulting blade excitations are in good agreement with the experimentally obtained data. As for the CFD calculations, the forced response results are close together for both applied ft>w pressures.

The differences in the unsteady effects due to the scaling are small compared to other effects like the coarsening of the flow data in radial direction due to

|

|

the interpolation from three profile cuts to the whole blade height or due to the transfer from the intermediate CFD mesh to the coarse FE surface elements. The applied extrapolation procedure from several blade-to-blade CFD planes can be more adequate for the bending mode shapes of the lowest blade eigen- frequencies, whose excitability increases successively to the highest value from the platform towards the airfoil tip.

The effects of mistuning are refected by the broad data range in the experimentally obtained displacement values. It is difficult to quantify damping, especially damping of a mistuned system, and to define from this a representative value for the tuned disk calculation. To quantify the displacements correctly however, it is important to have a good assumption of the mechanical damping of the disk assembly.

It is assumed that the observed small effects due to the scaling cannot be generalized to more complex configurations. In multi-stage turbomachines, higher harmonics will systematically be generated by e. g. wakes or blade-wake interactions from former stages.

Acknowledgments

The authors wish to thank ALSTOM (Switzerland) Ltd for their support of the work and for the permission to publish the results. The experimental data used in this paper was acquired in the research programme ADTurB, funded by the European Community under the Industrial and Material Technologies Programme (BriteEuram III), contract no. BPR-CT95-0124.