Design and nomenclature of aerofoil sections

In the early days, in fact until the late 1930s, very few aerofoil shapes were suggested by theory; the usual method was to sketch out a shape by eye, give it a thorough test and then try to improve on it by slight modifications. As a result of this method we had a mass of experimental data obtained under varying conditions in the various wind tunnels of the world. The results were interpreted in different ways, and several systems of units and symbols were used, so that it was difficult for the student or aeronautical engineer to make use of the data available.

It is true that this hit-and-miss method of aerofoil design produced a few excellent sections but it was gradually replaced by more systematic methods. The first step in this direction was to design and test a ‘family’ of aerofoils by taking a standard symmetrical section and altering the curvature, or camber, of its centre line. An early example of this resulted in the RAF series of aerofoils in the UK (RAF referred to the Royal Aircraft Factory). In Germany similar investigations were made with series named after the Gottingen Taboratory, and in America with the Clark Y series.

Tater sections have been based on theoretical calculations but, whatever the basis of the original design, we still rely on wind tunnel tests to decide the qualities of the aerofoil.

The naming and numbering of sections has also been rather haphazard. At first the actual number, such as RAF 15, meant nothing except perhaps that it was the 15th section to be tried. But the National Advisory Committee for Aeronautics in America soon attempted to devise a system whereby the letters and numbers denoting the aerofoil section served as a guide to its main features; this meant that we could get a good idea of what the section was like simply from its number. Unfortunately the system has been changed from time to time, and this has caused confusion; while the modern tendency to have more figures and letters in a number has resulted in such complication that the student finds it more difficult to get information about the section from the number than he did with some of the earlier ones. However since NACA sections, or slight modifications of them, are now used by nearly every country in the world, the reader may be interested in getting some idea of the systems.

The geometric features that have most effect on the qualities of an aerofoil section are –

(a) the camber of the centre line;

(b) the position of maximum camber;

(c) the maximum thickness, and variation of thickness along the chord;

and, perhaps rather surprisingly –

(d) the radius of curvature of the leading edge;

(e) whether the centre line is straight, or reflexed near the trailing edge; and the angle between the upper and lower surfaces at the trailing edge.

The NACA sections designed for comparatively low speed aircraft are based on either the four – or five-digit system; laminar flow sections for high subsonic speeds on the 6, 7 or 8 systems (the 6, 7 or 8 being the first figure, not the number of digits).

In each system there are complicated formulae for the thickness distribution, the radius of the leading edge and the shape of the centre line, but we need not worry about these; what is easier to understand is the meaning of the digits or integers, for instance, in the four-digit system –

(a) the first digit gives the maximum camber as a percentage of the chord;

(b) the second digit gives the position of the maximum camber, i. e. distance from the leading edge, in tenths of the chord;

(c) the third and fourth digits indicate the maximum thickness as a percentage of the chord.

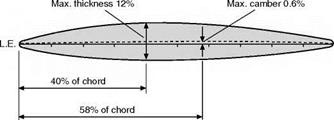

Thus NACA 4412 has a maximum camber of 4 per cent of the chord, the position of this maximum camber is 40 per cent of the chord back, and the maximum thickness is 12 per cent of the chord. In a symmetrical section there is of course no camber so the first two digits will be zero; thus NACA 0009 is a symmetrical section of 9 per cent thickness.

Notice that these are all geometric features of the section, but in later systems attempts are made to indicate also some of the aerodynamic characteristics, for instance, in the five-digit system –

(a) the ‘design lift coefficient’ (in tenths) is three-halves of the first digit;

(b) the second and third digits together indicate twice the distance back of the maximum camber, as a percentage of the chord;

(c) and the last two once again the maximum thickness.

The ‘design lift coefficient’ is the lift coefficient at the angle of attack for normal level flight, usually at about 2° or 3°.

Most of these sections have a 2 per cent camber, and in fact there is some relationship between the design lift coefficient and the maximum camber which has sometimes led to confusion about the meaning of the first digit; also the point of maximum camber is well forward at 15 per cent, 20 per cent or 25 per cent of the chord (which accounts for the doubling of the second and third digits to 30, 40 or 50). In fact the most successful, and so the most common of these sections, begins with the digits 230, followed by the last two indicating the thickness. Thus NACA 23012, as used on the Britten-Norman Islander, has a design lift coefficient of 0.3 (it also has 2 per cent camber), the maximum camber is at 15 per cent of the chord, while the maximum thickness is 12 per cent.

The forward position of the maximum camber in the five-digit sections results in low drag, but poor stalling characteristics, which explains why, when these sections are used near the root of a wing, they are often changed to a four-digit one (which gives a smooth stall) near the tip.

It should be noted that the position of maximum thickness (not indicated in either of these systems) is not necessarily the same as that of maximum camber, and in one British system eight digits were used so that this too could be indicated; two pairs of digits gave the thickness and its position, two other pairs the maximum camber and its position. Figure 3.25 illustrates 1240/0658 based on this system. For a symmetrical section the last four figures are omitted since they would all have been zero.

The reader may like to sketch for himself such sections as NACA 4412 and 23012, but he will have to judge the position of maximum thickness by eye.

In the NACA 6, 7 and 8 series, as in nearly all the NACA series, the last two digits again indicate the percentage thickness, but the other figures, letters, suffixes, dashes and brackets become so complicated that it is necessary to refer to tables. Most of these sections are particularly good for high subsonic speeds.

Many aircraft now use “tailor made” sections. This is particularly the case with transonic transport aircraft, which are designed to very fine limits to improve economy.

|

|