Conceptual and Preliminary Design Processes

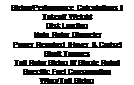

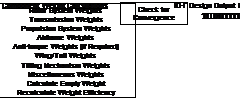

The methodology used in a conceptual or preliminary design study is an iterative process that begins with input specifications, such as the required payload and range of the helicopter. A series of performance and rotor sizing calculations based on these requirements are then undertaken using the elementary rotor theory described in previous chapters. The use of momentum theory in its various incarnations is very useful in this regard. Assessments of propulsive efficiency, lift-to-drag ratio, transmission power conversion efficiency, rotor tip speed, rotor figure of merit, and so on, are then performed. After these calculations are complete, a series of weight calculations are performed for the various components that make up the helicopter (rotor, blades, hub, airframe, engines, transmission, etc.). These weights are usually based on empirical equations, with the coefficients in these equations defined based on correlations to historical data. Next, these component weights are used to sum up the empty weight, the fuel weight for the mission is estimated, and the performance of the helicopter is recalculated. The updates are then substituted into the various weight equations and the process runs iteratively until convergence is achieved. Capital acquisition and direct operating costs are then evaluated.

|

|

|

The basic design methodology is depicted in Fig. 6.1. The logical sequence of this process allows trade studies to be performed and perhaps compared with other rotorcraft configurations. The intent is ultimately to select the best design that will meet the specified requirements at minimum cost. The conceptual and preliminary design process is then followed by a detailed design study at which the elements of the helicopter and its performance are examined in considerable detail. This is done using analysis, ground and wind tunnel testing, construction of a prototype, and finally flight testing. All of these steps involve considerable engineering time and large amounts of money. Flight testing is generally a protracted affair, often involving many months or even years of systematic testing before the helicopter is finally handed off to the customer.

Figure 6.1 Flowchart showing the conceptual design process for a generic rotorcraft.