– Thrust & Efficiency

Efficiency

In the early part of this book under the section ‘The Purpose of the Propeller’, it was stated, “The purpose of the propeller is to convert the engine torque into axial thrust, or propwash”. The statement can now be rephrased to read “the propeller produces the greatest axial thrust for the least amount of engine torque, when the maximum thrust/torque ratio is being produced”. How well the propeller converts the engine torque into axial thrust is measured by the propeller efficiency which in turn depends on several factors, namely, the prop’s diameter, solidity, number of blades, and prop blade loading to name a few. All of these factors and more will be covered in this chapter. Efficiency is therefore the best way to measure a prop’s performance; however it is not the whole story as will be revealed later. Thrust is a force that propels the aircraft through the air, but the efficiency is a measure of how well the prop succeeds in achieving this objective.

Given figures for a fictitious light aircraft, the propeller’s efficiency can be easily calculated using the following formula:

. 60 x TV x 100%

Efflclency = BHP x 33,000

Given: BHP = Brake Horsepower = 200

T = Thrust = 385 ponds

V = Air speed = 240 FPS = 142 kts

![]() . 60 x 385 x 100%

. 60 x 385 x 100%

Efficiency = 200 x 33,000

The above answer shows the prop’s efficiency to be 84%, which is a fairly good result; most metal props have a peak efficiency of around 80%. The remaining 16% of engine power

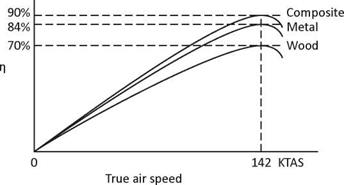

is used in counteracting the losses from friction, ancillary drive and exhaust gasses, etc. From the above formula a curve can be drawn with efficiency and true air speed as parameters, as in Diagram 10, Efficiency V. TAS. The curve is drawn for a fictitious aircraft example with a metal prop, showing the curve peaks at 84% prop efficiency at the design air speed of 142 knots. Above and below this figure the maximum efficiency deteriorates for a given speed. The lower curve is drawn for a theoretical wooden prop and shows its maximum efficiency peaks at 70%, due to greater blade thickness required for strength. A wood prop is not as structurally strong as a metal prop and so has to be built of thicker materials for extra strength, which is not as aerodynamically efficient. This is reflected in the wood prop’s curve being placed below that of the metal prop and the top curve representing a composite propeller, which is far more efficient than a metal or wooden prop. In comparison, marine propellers have an efficiency of around 56%.

|

Diagram 10, Efficiency V. True Air Speed |

Diagram 10, represents the efficiency for a fixed pitch prop and is similar to the graphs in Diagrams 6 and 7 . The sharp angle of the curve is due to the decreasing efficiency at the lower speed ratios (V/nd). Consider the ratio V/nd, if ‘V’ (true air speed) is zero then the prop’s efficiency would also be zero and the aircraft would not move from a stationary position. However, due to the propeller’s rotation it still moves a large mass of air rearwards at a low velocity producing ‘static thrust’. This is what moves the aircraft from a stationary position. Static prop thrust will be covered in greater detail in the section on ‘Propwash-thrust’; that is where the axial momentum theory takes over from the blade element theory.

An alternative formula to find the efficiency of the prop is as follows:

„rr. . thrust x TAS

Efflclency = drag x RPM

This formula is reduced to read thrust/drag ratio (T/D) and TAS/RPM ratio, otherwise known as the speed ratio. Any change in the prop’s helix angle due to a change in either RPM or true air speed will increase one ratio and decrease the other by a like amount. The thrust is required to be as high as possible, because greater thrust equates to greater forward speed for a given horsepower. Conversely, drag is required to be as low as possible – less drag gives a higher forward speed for a given thrust; that is, a high thrust/drag ratio is required. Too high a prop tip speed due to high RPM introduces many problems, which will be dealt with later.