Effects of Damage on Airfoil Performance

Ballistic vulnerability is an important consideration for military helicopters because they generally fly lower and slower than fixed-wing aircraft. Therefore, to minimize unexpected attrition of helicopter forces, any performance degradation must be minimized

and, if possible, prevented to ensure continued success on the battlefield. Compared to fixed-wing aircraft, however, helicopters have a much lower degree of system redundancy because the rotor itself provides all of the lift, propulsion and control. This means that any damage inflicted to the main or tail rotor systems is more likely to have serious consequences. Increased emphasis on improving survivability for US military helicopters has led to the Joint Live Fire (JLF) test program. These simulated live fire tests have helped to identify any especially vulnerable airframe components and aircraft subsystems early in the development cycle, so that potential problems can be rectified without incurring weight or cost penalties; see Foulk (1976) and Atkinson & Ball (1995).

While the use of modem composite materials give a high level damage tolerance to rotor blades, ballistic damage may still present significant problems in regard to the aerodynamic performance. A quantitative understanding of the aerodynamic effects of ballistic damage on the rotor system is, therefore, essential for the development and/or improvement of mathematical models representing these degraded aerodynamic effects in rotor analyses and to help assess reasonable risks in carrying on with a mission after the helicopter has been hit by a projectile. Unfortunately, the aerodynamic effects of blade damage will be a function of many interrelated parameters, including the location (chordwise and spanwise), physical nature of the damage and extent of damage. This makes the aerodynamic effects difficult to generalize. Yet it is clear that damage inflicted to the outboard sections of the blade are going to be aerodynamically more important on a rotor because of the high dynamic pressure in this area. At a minimum, a small damaged area on the blade may dramatically decrease section lift and increase drag. This will result in a loss of rotor thrust, increased rotor power requirements, the possibilities of premature blade stall, high control forces, and/or increased vibration levels. Even a minor performance degradation resulting from damage may incur much higher fuel consumption, and may seriously limit the ability of the helicopter to complete its assigned mission.

Some of the earliest recorded tests on the aerodynamic effects of ballistic damage was performed at NACA – see NACA (1936). This work examined the effects of machine gun and cannon fire on the lift and drag properties of fabric covered aircraft wings. More systematic experimental investigations were carried out by Reece (1952a, b). The results, which included measurements of the drag increase incurred by different damaged configurations, became the basis for later studies by Chang & Stearman (1980) and Westkaemper (1980). However, it is difficult to properly quantify ballistic damage effects on the aerodynamic characteristics of helicopter rotor blades because of the very 3-D and time-varying flow environment. Helicopter blade sections are often quite different physically and aerodynamically to those used on fixed-wing aircraft, so it may not be appropriate to extrapolate any known results to helicopters. Eastman (1993) has made some attempt to assess the aerodynamic effects on a UH-60 main rotor blade subject to ballistic damage. Leishman (1993, 1996) has made experimental measurements of the aerodynamic characteristics of series of helicopter blade sections with both simulated and actual ballistic damage. Other measurements on damaged airfoil sections have been conducted by Erwin & Render (2000).

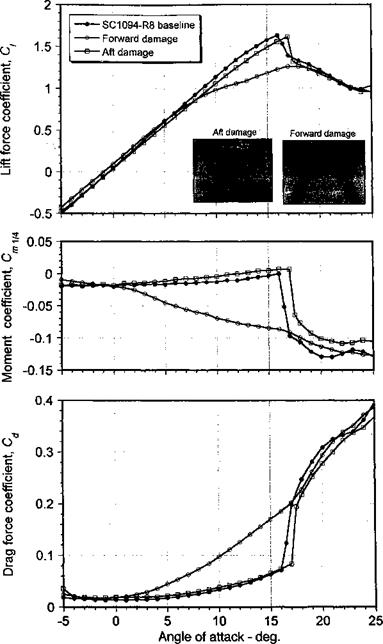

These tests have all revealed that ballistic damage significantly degraded the aerodynamic characteristics of the blade section, with a loss in lifting performance, changes in the pitching moment characteristics and a substantial increase in sectional drag. For example, Fig. 7.55 shows the measured aerodynamic characteristics of an undamaged SC1095-R8 airfoil section relative to two damaged specimens; one with simulated damage toward the leading edge and the other with damage near the trailing edge. The leading edge damaged blade section had a circular hole cut through the blade spar, whereas the damage at the

|

Figure 7.55 Comparison of the lift, moment and drag coefficients of an undamaged airfoil section versus two specimens with simulated damage at the leading – and trailing-edges, respectively. Mach number = 0.3, Reynolds number = 2 x 106. Data source: Leishman (1996). |

trailing edge was cut into the paper honeycomb structure. It is apparent that damage near the leading edge of the section is more critical in terms of its effects on the aerodynamics than damage at the trailing edge. Notice that with leading edge damage, the lift-curve-slope decreases dramatically at approximately 6 degrees, yet the lift still continues to increase linearly after this point until stall occurs. This elbow in the lift-curve-slope is most likely

the result of increased flow from the lower surface up through the hole to the upper surface at higher angles of attack, that is, a “jet in a crossflow effect” – see Erwin & Render (2000). Flow visualization (inset in Fig. 7.55) has shown that this tends to fix the point of flow separation over the range from lower angles of attack through the stall angle. For increasing angles of attack this separation extends over large parts of the blade chord and span. Interestingly, while reaching a lower maximum lift coefficient than either the baseline or the specimen with trailing edge damage, the final stall AoA is at least 3° higher. The pitching moment variation suggests that leading edge damage caused an aft movement of the aerodynamic. center, which would probably not result in any adverse aeroelastic effects on the rotor. However, the drag for the forward damaged blade section is much larger than the baseline, growing from 1.4 times the baseline value at lower angles of attack to more than 2.5 times at higher angles of attack. This would have a very major effect on rotor performance and blade loads.