Deep Stall

Deep stall requires a stable longitudinal trim point beyond the stall. If, in a stall, the combination of longitudinal trim and control is insufficient to nose the airplane down to an unstalled attitude, the condition is called a deep stall or locked-in deep stall. In some cases short of a locked-in stall, control power is so marginal that recovery takes place slowly or requires unusual measures, such as rolling or sideslipping the airplane or rocking the airplane in pitch. Deep stall was first encountered in-flight on a Handley Page Victor bomber in 1962. Hawker Siddeley’s Trident 1C, British Aircraft Corporation’s BAC 1-11, and the Soviet Tu 134 subsequently experienced deep stalls. The details of a BAC 1-11 deep-stall crash were widely disseminated, leading to a new series of wind-tunnel tests of airplanes then under development, such as the McDonnell Douglas DC-9. There were subsequent accidents in which deep stall was suspected, notably on the Boeing 727, a jet that resembles the BAC 1-11. The Canadair (Bombardier) Challenger CL600 also resembles the BAC 1-11. A CL600 and a variant were lost in deep-stall accidents.

There is an underlying cause for deep stall in airplanes with horizontal tails mounted on top of the vertical tail, in the T position. The wing trailing vortex system is normally rolled up into concentrated vortices by the time it reaches the horizontal tail. In unstalled flight the rolled-up vortices are generally behind the wing tips, quite a bit outboard of the horizontal tail span. This weakens the downwash at the horizontal tail, a source of nose-up pitching moment.

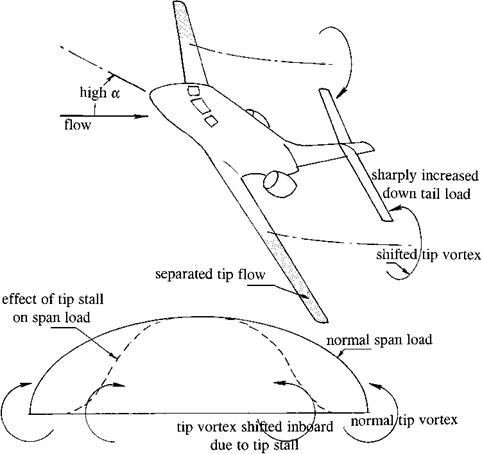

In airplanes prone to deep stall the outboard wing panels stall first when the angle of attack is increased. In effect, new wing tips are formed at the tips of the unstalled wing portion. The rolled-up trailing vortices are now quite close in span to the horizontal tail. If the horizontal tail is in the T location, at the top of the vertical tail, the rolled-up vortices at high angles of attack are roughly in the same plane as the horizontal tail, the position to exert a maximum downwash and nose-up pitching moment. The aerodynamic flow conditions for a deep stall on an airplane with a T-tail are illustrated in Figure 14.4.

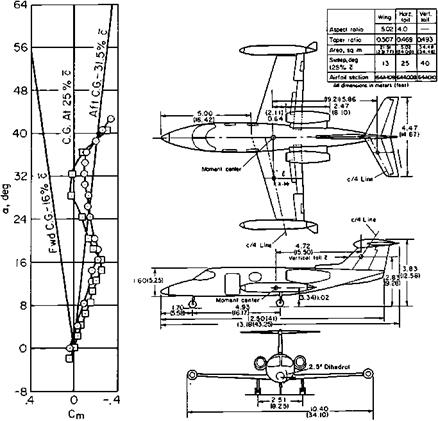

NASA Ames 40- by 80-Foot Wind Tunnel tests of a full-scale Learjet, Inc., Model 23 executive jet provide a clear example of a deep stall at an aft center of gravity position (Soderman and Aiken, 1971). The airplane has a T-tail and a moderate wing sweep of 13 degrees. At the aft center of gravity position of 31.5 percent MAC, the data show a stable trim point at an angle of attack of 39 degrees, well beyond the stall. This is with full airplane nose-down stabilizer trim of 0.4 degree. With full 15-degree down-elevator added for recovery, the diving moment is insufficient to recover unstalled flight (Figure 14.5).

|

Figure 14.4 Aerodynamic flows for deep stall for an airplane with a T-tail. Separated wing tip flow shifts the tip vortices inboard. Cores of the shifted tip vortices are in line with the T-tail, giving maximum downflow and a sharply increased down tail load. |

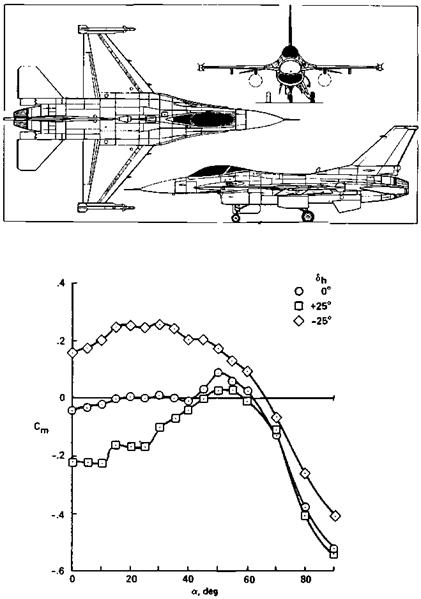

The General Dynamics F-16 can also get into a deep stall (Figure 14.6). The F-16 has a special manual pitch override stick switch giving the pilot full tail travel, canceling roll and stability augmentation functions. This is to allow the pilot to rock out of a deep stall, in phase with residual pitch oscillations (Anderson, Enevoldson, and Nguyen, 1983). They report:

The instructions [flight manual] note that if no increase in attitude is discerned (with full [nose-up] pitch control), the pilot should wait 3 seconds and apply full reverse control. If the nose does not continue down with full forward stick, but reverses and starts up, full back stick must be applied to continue rocking the aircraft. The pitch oscillation has a period of approximately 3 seconds and the pilot is warned that rapid cycling of the control will be ineffective.

As many as four cycles are needed to break the F-16’s deep stall. Proper rock phasing is difficult if the airplane is in a roll oscillation, since severe rolling masks the airplane’s pitching motions. The ultimate fix for F-16 deep stall was a 25-percent increase in horizontal tail size, incorporated in all production airplanes (Chambers, 2000).

|

Figure 14.5 Pitching moment coefficient variation with angle of attack for a full-scale Learjet Model 23, as tested in the NASA Ames 40- by 80-foot wind tunnel. At an aft center of gravity position of 31.5 percent MAC there is a stable trim point at an angle of attack of 39 degrees. This is with full nose-down trim. Circle symbols are flaps up, squares are flaps down. Addition of full down-elevator angle is insufficient to regain unstalled flight. (From Soderman and Aiken, NASA TN D-6573, 1971) |

The McDonnell Douglas C-17 military cargo airplane also has a locked-in deep stall potential because of its T-tail. However, in contrast to the F-16 case, a sophisticated angle of attack limiter scheme prevents deep stalls from occurring. A control column pusher can prevent deep stall by overcoming the pilot pull force that is leading to a stall with an opposing push force. This approach was rejected because of reliability, particularly the possibility of a single point failure (Iloputaife, 1997).

The deep stall prevention system selected for the C-17 relies on a measured angle of attack providing an initial aural warning and shaking of the control column at a soft limit angle of attack. If the angle of attack continues to increase, or if airspeed drops at an excessive rate, the attack limiter system switches on, an angle of attack command system having a hard limit.

Interesting design features of the C-17 angle of attack limiter system are the array of six fuselage-mounted vane flow direction sensors and the provisions to switch the limiter in and out without causing undesirable transients or secondary stalls. The sensor array permits the system to operate correctly under sideslip conditions, which affect individual vane readings, and with redundancy in the face of vane failure or damage.

|

Figure 14.6 Variation in pitching moment coefficient with angle of attack for the General Dynamics F-16A, with zero and maximum tail surface angles. Even with full nose-down control (+25 degrees) there is a stable or locked-in trim point at an angle of attack of 60 degrees. (From Nguyen, Ogburn, Gilbert, Kibler, Brown, and Deal, NASA TP-1538, 1979) |