Efficient propulsion

When the aircraft shown in Fig. 6.3 start moving, the useful power is the product of the thrust and the aircraft speed. We can therefore define a form of propulsive efficiency as the ratio:

the useful power

the useful + the rate at which energy is used to increase power the kinetic energy in the slipstream or jet

This is known as the Froude efficiency.

Thrust = 50 x 80 = 4000 N

Thrust = 50 x 80 = 4000 N

Energy rate = 50 x 80 = 160 000 W

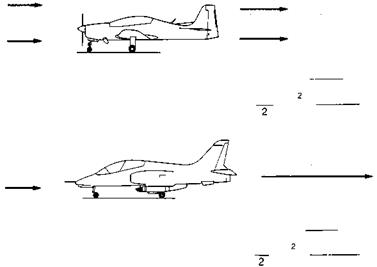

Fig. 6.3 Static thrust production by a propeller and jet compared

The large disc area of the propeller enables it to work on a larger mass of air per second, but with a lower slipstream or jet velocity than the jet-engined aircraft. Although the two aircraft are producing the same thrust, the jet-engined aircraft is transferring energy to the slipstream five times faster, so it needs to burn fuel at a much higher rate

From the discussions above, we can see that the Froude efficiency will be higher for the propeller-driven aircraft at any given speed and thrust since it is transferring energy to the air at a lower rate.

Froude efficiency improves with flight speed for both jet and propeller – driven aircraft, but if it were not for compressibility problems, propeller propulsion would always have the higher Froude efficiency at any particular speed and thrust. As we shall show, at high speeds, this theoretical advantage of the propeller is extremely difficult to realise in practice.

From the example of the propeller and jet-propelled aircraft given above we can see that, for efficient propulsion, it is better to generate thrust by giving a small change of velocity to a large mass of air, than by giving a large change in velocity to a small mass. The proof of this may be found in Houghton and Carpenter (2003). In simple terms, it arises because thrust per kilogram of air is related to the change in air velocity whereas relative energy expenditure rate depends on the change in the square of the velocity.

Of all the propulsion systems currently employed, propeller systems are potentially the most efficient, since they involve relatively large masses of air and small velocity changes. Pure jet engines are inherently less efficient, because, for an equal amount of thrust, they use much larger changes of velocity, and smaller masses of air.

It is interesting to note that one of the most theoretically efficient propulsion systems so far devised is the flapping wing of a bird, since this utilises the maximum possible area, and hence the largest air mass for a given overall dimension. Helicopters have a similar theoretical advantage, although in practice, technical problems have always resulted in their being rather inefficient. This raises the important point that the best propulsion system is the one that can be made to work most efficiently in practice.

The Froude efficiency defined above, is only one aspect of the efficiency of propulsion. We have to consider the efficiency of each stage of the energy conversion process. In a simple turbo-jet engine, power is produced by adding energy to the air stream by direct heating, which can eliminate some of the intermediate steps of a propeller system. Many other factors, such as the amount of thermal energy thrown out with the exhaust, contribute to the overall inefficiency. We shall discuss these contributions later in our more detailed descriptions of particular propulsion devices.

Although the Froude efficiency of the turbo-jet may be lower than that of a propeller system, it has the advantage that there is virtually no limit to the speed at which it can be operated, and it works well at high altitude. The ratio of power to weight can also be very high for jet engines.

One of the most important requirements for efficient propulsion, is to ensure that all of the components, including the aircraft itself, produce a high efficiency at the same design operating condition. The correct matching of aircraft and powerplant is of major importance. In many cases, a new engine must be designed, or an old one extensively modified, to meet the needs of the new aircraft design. As we shall see later, compromises often have to be made, and in some cases we need to sacrifice efficiency in the interests of other considerations, such as high speed, or low capital cost.