Reducing boundary layer normal pressure (form) drag

In order to reduce the boundary layer normal pressure drag, it is important to ensure that the pressure gradient is not strongly adverse, which means that the

|

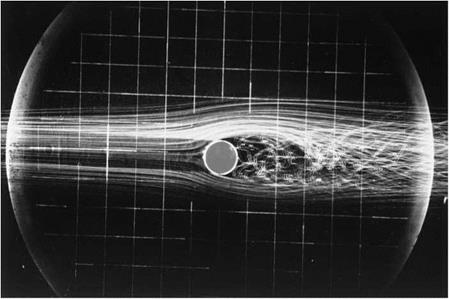

Fig. 4.2 Flow separation and wake formation behind a circular cylinder The difference in pressure between the front and rear results in normal pressure drag (form drag) (Photo courtesy of ENSAM, Paris) |

Circular rod producing the same amount of drag

|

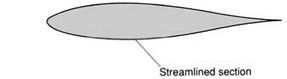

Fig. 4.3 The benefits of streamlining The tiny dot represents a circular rod which would produce the same amount of drag as this streamlined section (at a Reynolds number of 6 x 106) |

tail of the body should reduce in depth or cross-sectional area gradually. This leads to the classical streamlined shape shown in Fig. 4.3.

The worst possible shape in terms of normal pressure drag, is a blunt object with sharp corners, since separation will occur at the corners, leaving a low pressure over the whole of the rear.

The advantages of streamlining

The streamlined shape shown in Fig. 4.3 is a symmetrical aerofoil and at zero angle of attack it has a drag coefficient of around 0.03 based on frontal area (0.005 based on plan area). This may be compared with the drag coefficient of a circular cylinder which is 0.6 (at a Reynolds number of 6 x 106). This means, that a circular rod would produce 20 times as much drag as the streamlined section of the same depth. Looking at it another way, a 5 mm diameter wire would produce as much drag as a streamlined fairing 100 mm deep. We can, therefore, see why it was so necessary to eliminate the external bracing wires used on vintage aircraft.