Spring Tabs

Spring tabs overcome the main problem of flying tabs, which do not provide the pilot with control of the main surface at low speeds, as when taxiing. In spring tabs, the pilot’s linkage to the tab is also connected to the main surface through a spring. If the spring is quite stiff, good low-speed surface control results. At the same time, a portion of the pilot’s efforts goes into moving the main surface, increasing controller forces.

Spring tabs have the useful feature of decreasing control forces at high airspeeds, where control forces usually are too heavy, more than at low airspeeds. At low airspeeds, the spring that puts pilot effort into moving the main surface is stiff relative to the aerodynamic forces on the surface; the tab hardly deflects. The reverse happens at high airspeeds. At high airspeeds the spring that puts pilot effort into moving the main surface is relatively weak compared with aerodynamic forces. The spring gives under pilot load; the main surface moves little, but the spring gives, deflecting the tab, which moves the main surface without requiring pilot effort.

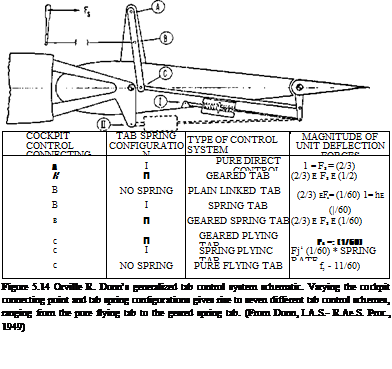

The earliest published references to spring tabs appeared as Royal Aircraft Establishment publications (Brown, 1941; Gates, 1941). NACA publications followed (Greenberg, 1944; Phillips, 1944). But the credit for devising a generalized control tab model that covers all possible variations (Figure 5.14) belongs to Orville R. Dunn (1949). The Dunn model uses three basic parameters to characterize spring tab variations, which include the geared tab, the flying tab, the linked tab, and the geared spring tab.

Although the derivation of pilot controller force equations for the different tab systems involve only statics and the virtual work principle, the manipulations required are surprisingly complex. As is typical for engineering papers prepared for publication, Dunn provides only bare outlines of equation derivations. Readers of the 1949 Dunn paper who want to derive his final equations should be prepared for some hard labor.

Dunn concluded that spring tabs can produce satisfactory pilot forces on subsonic transport-type airplanes weighing up to several million pounds. At the time of Dunn’s paper, spring tabs had indeed been used successfully on the Hawker Tempest, the Vultee Vengeance rudder, all axes of the Canberra, the rudder and elevator of the Curtiss C-46 Commando, the Republic XF-12, and the very large Convair B-36 bomber. They also would be used later on the Boeing B-52 Stratofortress. Dunn’s account of the DC-6 development tells of rapid, almost overnight, linkage adjustments during flight testing. The major concerns in spring tab applications are careful design and maintenance to minimize control system static friction and looseness in the linkages.

The B-19 experience encouraged Douglas engineers to use spring tabs for many years afterwards. Both the large C-124 and C-133 military transports were so equipped. The

|

DC-6, -7, -8, and -9 commercial transports all have some form of spring tab controls, the DC-8 on the elevator and the DC-9 on all main surfaces, right up to the latest MD-90 version. In that case, the switch was made to a powered elevator to avoid increasing horizontal tail size to accommodate the airplane’s stretch. A powered elevator avoids tab losses and effective tail area reductions because tabs move in opposition to elevator travel.

The Douglas DC-8 and -9 elevator control tabs are actually linked tabs, in which pilot effort is shared between the tab and the elevator. This gives the pilot control over the elevator when on the ground. The DC-8 and -9 elevator linked tabs are inboard and rather small. The inboard linked tabs are augmented by outboard geared tabs, which increase the flutter margin over single large linked tabs. The DC-9 elevator controls are hybrid in that hydraulic power comes in when the link tab’s deflection exceeds 10 degrees. Spring tabs serve a backup purpose on the fully powered DC-8 ailerons and rudder and on the DC-9 rudder. The tabs are unlocked automatically and used for control when hydraulic system pressure fails. The same tab backup system is used for the Boeing 727 elevator.

The spring tab design for the elevators of the Curtiss C-46 Commando was interesting for an ingenious linkage designed by Harold Otto Wendt. Elevator surfaces must be statically balanced about their hinge lines to avoid control surface flutter. Spring tabs should also be statically balanced about their own hinge lines. Spring tab balance weights and the spring mechanisms add to the elevator’s weight unbalance about its hinge line. Wendt’s C-46 spring tab linkage was designed to be largely ahead of the elevator hinge line, minimizing the amount of lead balance required to statically balance the elevator.

Spring tabs appear to be almost a lost art in today’s design rooms. Most large airplanes have hydraulic systems for landing gear retraction and other uses, so that hydraulically operated flight controls do not require the introduction of hydraulic subsystems. Furthermore, modern hydraulic control surface actuators are quite reliable. Although spring tab design requires manipulation of only three basic parameters, designing spring tabs for a new airplane entails much more work for the stability and control engineer than specifying

parameters for hydraulic controls. Computer-aided design may provide spring tabs with a new future on airplanes that do not really need hydraulically powered controls.