Wing plan shape

The way in which the lift per metre of span varies along the span, depends on (among other things) the way in which the chord varies along the span. For untapered rectangular planform wings, most of the trailing vorticity is shed near the tips. In this case, the downwash will be greatest near the tips. If a tapered wing is used, the lift is increased at the centre, and trailing vorticity is produced more evenly along the span.

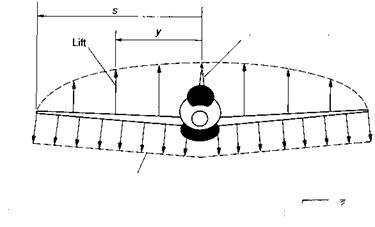

Theoretical analysis indicates that for a given amount of lift, the smallest amount of trailing vortex (induced) drag will be produced when the downwash is constant along the span. The same analysis also shows that the constant downwash condition is obtained if the lift per metre of span varies from zero at the tips, to a maximum at the centre, following an elliptical relationship, as indicated in Fig. 2.11. An elliptical spanwise variation of lift thus represents a theoretical ideal case for minimum trailing vortex drag.

On aircraft with unswept wings, an elliptical variation of lift can be produced by using a wing where the chord varies elliptically with distance along the span. Such wings have rarely been built, but one notable example

Constant downwash

Constant downwash

Lift/metre of span at distance у from centre = Lift at centre

Fig. 2.11 Elliptical variation of lift along the span

This variation gives a constant downwash along the span, and the minimum amount of trailing vortex (induced) drag shown in Fig. 2.12 is the Spitfire wing, which has a precise elliptical variation of chord.

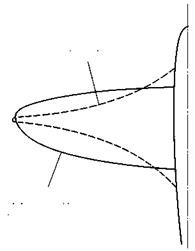

There are manufacturing problems associated with an elliptical planform and furthermore, this shape is not ideal from a structural point of view. The structural designer would prefer the lift forces to be concentrated near the centre or root of the wing, so as to reduce bending moments. He would also like the depth of the wing spars to reduce towards the tips to maintain a constant level of bending stress. If the wing section shape were then to be the same at all positions, the chord would have to reduce accordingly. This would lead to the form of wing shown by the dashed lines of Fig. 2.13. The trailing vortex drag depends on the lift required, which in turn depends on the aircraft weight. A wing of this better structural shape should be lighter than the elliptical wing. The elliptical planform would only represent the shape for minimum induced drag if the weight of the wing structure were negligible. This is never the case, and by using a more efficient structural shape, it is possible to save weight. It therefore follows that for a real aircraft, the lowest drag would be given by a planform shape that was somewhere between the two extremes shown in Fig. 2.13; a compromise between the aerodynamic and structural ideals. In fact, a straight taper gives a good compromise, and has the advantage of being easy to construct. This factor shows the importance of integrating all aspects of aircraft design, and not trying to optimise any one feature in isolation.

The fact that an elliptical planform does not represent the true minimum drag shape for a practical aircraft was shown by Prandtl in 1933. It should be noted that the Spitfire was originally conceived with a simple tapered wing. The elliptical planform was adopted largely because of a need to increase the

|

|

|

Fig. 2.12 Elliptical and tapered planforms The Spitfire (upper) had a wing with an elliptical variation of chord along the span. This theoretically gives the minimum amount of trailing vortex drag for a given wing area The Mustang (lower) used a wing with conventional taper, but improved aerofoil section. Merlin-engined versions of the two aircraft had similar performance, the Mustang being in some respects superior The Spitfire shown in the photograph is actually a late Griffon-engined Mk-14 |

Preferred planform for purely structural considerations

Preferred planform for purely structural considerations

Elliptical planform for minimum trailing vortex (induced) drag

Fig. 2.13 Wing shapes for minimum trailing vortex (induced) drag and for structural efficiency. A straight taper gives a good compromise and is easier to manufacture The elliptical planform shown is that of the Spitfire section depth around mid-span to accommodate ammunition boxes and the undercarriage mechanism.

When engines are mounted on the wings, their weight reduces the bending stresses on the inboard sections of the wing. Little or no taper is thus required for the inboard sections. When an untapered centre section with tapered outer sections is used, the overall wing planform approximates roughly to the elliptical aerodynamic ideal. Designers rarely seem to have taken advantage of this, but the DH Canada Dash-8 (Fig. 13.4) is one example.

On a straight-tapered or untapered wing, an elliptical distribution of lift may be produced by using a variation of incidence along the span; in other words, by twisting the wing. Spanwise variation of wing-section camber is also used in some designs.

For a given aircraft weight and flight altitude, the use of a fixed amount of twist or camber variation can only produce a truly elliptical lift distribution at one speed. This is not necessarily a major objection, however, as many other aspects of aircraft design are optimised for a preferred combination of speed, height and weight, or cruise condition.