Tip Losses and Other Viscous Losses

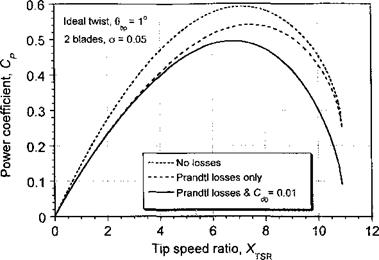

The separate effects of viscous drag and Prandtl tip losses on the turbine power output is shown in Fig. 13.15. Notice that both types of nonideal losses tend to decrease power output (decrease turbine efficiency). Taken together they comprise about a 15% loss of efficiency, which is fairly close to the results obtained in practice for operating conditions that do not involve any blade stall (see Fig. 13.6).

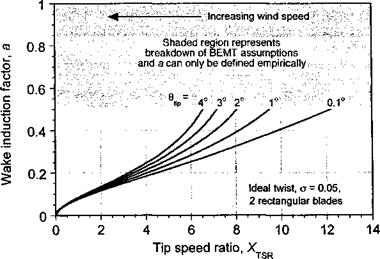

Of interest is the induced velocity or axial induction factor a as a function of tip-speed ratio. In the ideal case (hyperbolic blade twist) the induction factor is uniform over the disk. The behavior of the induction factor is shown in Fig. 13.16 for several blade pitch

|

Figure 13.15 Turbine power output as a function of TSR showing the separate effects of viscous drag and Prandtl tip losses. |

angles. Notice that the largest induction factors arc obtained at the highest tip speed ratios (lowest wind speeds). This is because the induced velocity is a relatively high fraction of the wind speed at low wind speeds (high values of Xtsr) and becomes an increasingly smaller fraction as wind speed builds (low values of Xtsr)- Furthermore, at low wind speeds there is a possibility of two flow directions existing at the rotor disk, which can only be represented, albeit approximately, using an empirical relationship between Cj and a, as previously discussed. Another factor that limits the applicability of the BEMT is that at higher wind speeds there is the possibility of blade stall, which also needs to be considered if the induction factor is to be predicted accurately.

|

Figure 13.16 Variation of axial induction factor as a function of TSR for a wind turbine with ideally twisted blades giving uniform induction factor. |

|

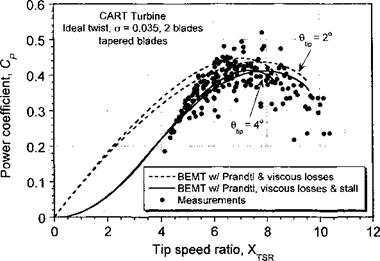

Figure 13.17 Turbine power output as a function of TSR showing the effects of blade stall. Data source: Measurements from two-bladed wind turbine, courtesy of NREL. |