Laminar flow control by boundary-layer suction

Distributed suction acts in two main ways to suppress laminar-turbulent transition. First, it reduces the boundary-layer thickness. Recall from Section 7.9 that for a fixed pressure gradient a critical Reynolds number based on boundary-layer thickness must be reached before transition is possible. Second, it creates a much fuller velocity profile within the boundary layer, somewhat similar to the effect of a favourable pressure gradient. This makes the boundary layer much more stable with respect to the growth of small disturbances (e. g. Tollmien-Schlichting waves). In effect, this also greatly increases the critical Reynolds number. The earliest work on laminar-flow control (LFC) including the use of suction was carried out in Germany and Switzerland during the late 1930s in wind-tunnels.* The first flight tests were carried out in the United States in 1941 using a B-18 bomber fitted with a wing glove. The maximum flight speed available and the chord of the wing glove limited the transitional Reynolds number achieved to a lower value than that obtained in wind-tunnel tests.

Research on suction-type LFC continued up to the 1960s in Great Britain and the United States. This included several flight tests using wing gloves on aircraft like the F-94 and Vampire. In such tests full-chord laminar flow was maintained on the wing’s upper surface at Reynolds numbers up to ЗО x 106. To achieve this transition delay exceptionally well-made smooth wings were required. Even very small surface roughness, due to insect impact, for example, caused wedges of turbulent flow to form behind each individual roughness element. Further flight tests in the United States and Great Britain (the latter used a vertically mounted test wing on a Lancaster bomber) revealed that it was much more difficult to maintain laminar flow over swept wings. This was because swept leading edges bring into play more powerful routes to transition than the amplification of Tollmien-Schlichting waves. First of all, turbulence propagates along the leading edge from the wing roots, this is termed leading-edge contamination. Secondly, completely different and more powerful

disturbances form in the boundary layer over the leading-edge region of swept wings. These are called cross-flow vortices.

Owing to the practical difficulties and to the relatively low price of aviation fuel, LFC research was discontinued at the end of the 1960s. More recently, with the growing awareness of the environmental requirements for fuel economy and limiting engine emissions, it has been revived. LFC is really the only technology currently available with the potential for very substantial improvement to fuel economy. For transport aircraft, the reduction in fuel burnt could exceed 30%. Recent technical advances have also helped to overcome some of the practical difficulties. The principal such advances are:

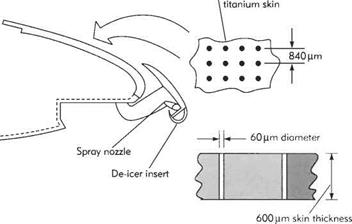

(i) Krueger (Fig. 8.33) flaps at the leading edge that increase lift and act to protect the leading-edge region from insect impact during take-off and climb-out;

(ii) Improved manufacturing techniques, such as laser drilling and electron-beam technology, that permit the leading edges to be smooth perforated titanium skins;

(iii) The use of hybrid LFC.

The application of the first two innovations is illustrated in Fig. 8.33. Perforated skins give distributed suction which is more effective than the use of discrete suction slots. Hybrid LFC would be particularly useful for swept-back wings because it is not possible to maintain laminar flow over them by means of natural LFC alone. This depends on shaping the wing section in order to postpone the onset of an adverse pressure gradient to as far aft as possible. Tollmien-Schlichting waves can be suppressed in this way, but not the more powerful transition mechanisms of leading-edge contamination and cross-flow vortices found in the leading-edge region on swept wings. With hybrid LFC, suction is used only in the leading-edge region in order to suppress the cross-flow vortices and leading-edge contamination. Over the remainder of the wing where amplification of Tollmien-Schlichting waves is the main route to

|

Electron-beam perforated

Fig. 8.33 Leading-edge arrangement for 1983-1987 flight tests conducted on a JetStar aircraft at NASA Dryden Flight Research Center. Important features were: (1) Suction on upper surface only; (2) Suction through electron-beam-perforated skin; (3) Leading-edge shield extended for insect protection; (4) De-icer insert on shield for ice protection; (5) Supplementary spray nozzles for protection from insects and ice Source: Based on Fig. 12 of Braslow (2000) ibid |

transition, wing-profile shaping can be used to reduce the effects of an adverse pressure gradient. In practice, it is easier to achieve this for the upper surface only. Owing to the higher flow speeds there, the upper surface produces most of the skin – friction drag. Hybrid LFC wings were extensively and successfully flight tested by Boeing on a modified 757 airliner during the early 1990s. Although, LFC based on the use of boundary-layer suction has yet to be used in any operational aircraft, the technology in the form of the less risky hybrid LFC has been established as practically realizable. In this way, based on proven current technology, a 10 to 20% improvement in fuel consumption could be achieved for moderate-sized subsonic commercial aircraft.

A detailed account of LFC technology and its history is given by Braslow.[70]