Reduction of wave drag

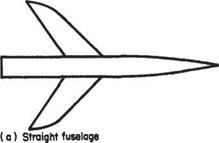

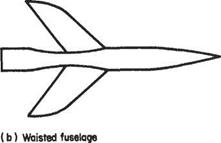

Aspects of this have been covered in the discussion of swept wings in Section 5.7 and of supercritical aerofoils in Sections 7.9 and 8.2. In the latter case it was found that keeping the pressure uniform over the upper wing surface minimized the shock strength, thereby reducing wave drag. A somewhat similar principle holds for the whole wing-body combination of a transonic aircraft. This was encapsulated in the area rule formulated in 1952 by Richard Whitcomb[75] and his team at NACA Langley. It was known that as the wing-body configuration passed through the speed of sound, the conventional straight fuselage, shown in Fig. 8.41a, experienced a sharp rise in wave drag. Whitcomb’s team showed that this rise in drag could be considerably reduced if the fuselage was waisted, as shown in Fig. 8.41b, in such a way as to keep the total cross-sectional area of the wing-body combination as uniform as possible. Waisted fuselages of this type became common features of aircraft designed for transonic operation.

The area rule was first applied to a production aircraft in the case of the Convair F-102A, the USAF’s first supersonic interceptor. Emergency application of the area rule became necessary owing to a serious problem that was revealed during the flight tests of the prototype aircraft, the YF-102. Its transonic drag was found to exceed the thrust produced by the most powerful engine then available. This threatened to

|

|

|

Fig. 8.41 Application of the area rule for minimizing wave drag |

jeopardize the whole programme because a supersonic flight speed was an essential USAF specification. The area rule was used to guide a major revised design of the fuselage. This reduced the drag sufficiently for supersonic Mach numbers to be achieved.