Failure cueing

Engineering an effective engine failure warning in a multi-engine installation can be a difficult task. Some systems are triggered by low oil pressure as the engine-driven pump slows down but these systems often suffer from significant delays. Another approach is to compare the power output of the engines and trigger the warning if the difference exceeds a threshold value. This type of system can be problematic if the power-sharing characteristics of the engine governors are not well matched.

7.6.5.4 Sudden engine failures

As is the case with single-engine machines the aim of sudden engine failure testing in forward flight is to establish the intervention time available and to check that there are no handling implications. Testing in the low speed flight regime is also required to establish the aircraft performance and to determine the optimum techniques for landing or achieving a safe flight condition. The intervention time is established using rotor speed as the controlling parameter in much the same manner as for total power loss testing. In a multi-engine installation the rotor speed decay rate will be clearly much slower, however, an incremental approach is equally important. The same range of parameters will affect this rate of decay as for the single-engine helicopter discussed in Section 2.12. In addition the acceleration characteristics of the functioning engine will have an effect as the faster the engine acceleration the slower the NR decay will be. As described before sudden engine failures should be made in level flight starting at VMP and then progressing to selected speeds throughout the flight envelope. It may also be necessary to conduct failures at the combination of speed and power normally used for climbing flight.

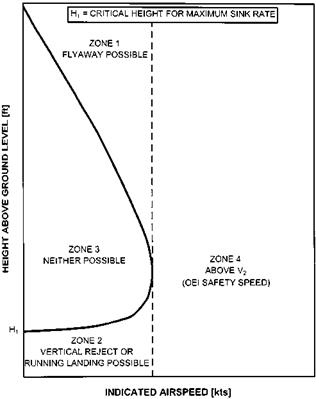

The most critical area for powerplant failures and hence for testing is in the hover and low speed regime. Here the testing is used to establish the techniques for conducting flyaways and vertical or forward rejects. Advice to operational crews is given in the form of a height/velocity diagram in the same way as is done for single-engine aircraft. Figure 7.14 shows an example of an avoid curve that has been produced as a result of this type of testing. The diagram is divided into four zones defined by height and airspeed. The important area is Zone 3: in this zone the aircraft is not able to perform a flyaway and a safe vertical or forward reject is also not possible. It should be remembered that the avoid curve may be sized on the assumption that at the boundary

|

Fig. 7.14 Height/velocity diagram for a multi-engine helicopter. |

a given level of aircraft damage may occur. The combination of height and speed from which a vertical or forward reject is possible depends mainly on the rotor decay characteristics for the test conditions and the energy-absorbing properties of the undercarriage. During the tests the rate of descent is kept within the undercarriage design limits and the minimum NR is noted. The results are often compared with the predictions of any model used as part of the planning and risk assessment so that the model may be used to generate the advice given to operational crews.

For flyaway testing a model can be used to determine the optimum technique to be used to minimize height loss and one of the aims of the test programme is to establish if the technique is easy and repeatable to fly. If no model is available or the manufacturer fails to recommend a technique then a variety of flyaway profiles will have to be tried to establish the best method. The difficulty of flying any proposed technique must be borne in mind as the operational pilot will not be expecting a failure and will not be as adept or practised as the test pilot(s) conducting the trial. Accurate trends and therefore meaningful predictions can only be made if the chosen technique is flown consistently. At some point, however, it is often necessary to conduct testing to determine the sensitivity of the avoid curve data to a non-optimum technique.

Once the flyaway technique has been established testing starts by determining that the specified intervention time is achievable in the hover. For this the aircraft is hovered well clear of the ground and the flyaway profile practised. Initially the engine failure is coupled with a simultaneous flyaway. Then the intervention time is gradually increased by the pilot reacting to the failure at lower values of rotor speed (NR1). Once the NR1 that equates to the required intervention time has been found it is used for the remainder of the hover flyaway testing. The total height loss suffered between the failure and the achievement of a safe flight condition is recorded as this can be used in defining the initial height AGL for the tests nearer the ground. It has been found from personal experience that the height loss during a flyaway is affected to a large extent by the initial hover height. The stronger visual cues to pitch attitude and RoD at lower heights assist the pilot in flying the manoeuvre and so help to reduce the height loss. To find the height loss near the ground the hover height used is reduced incrementally until consistent results are achieved with realistic visual cues. Typically a minimum height of 50 feet AGL is set for the recovery and the failure height set to ensure this limit is respected.

There are a number of risk reduction measures that are taken with this type of testing. As already stated an accurate predictive model reduces the chances of unpleasant surprises. Where possible two crew members are carried and the flight monitored by telemetry. It is worth noting again that for hydro-mechanical fuel control systems experience has shown that if cockpit controls are used to ‘top’ an engine, airframe vibration can cause the control to move. For this reason the power output of the ‘good’ (non-failed) engine requires careful monitoring to ensure that the settings remain unchanged. This can be achieved by reviewing the telemetry traces immediately after each test to check that when the maximum available power was demanded the torque, engine speed, and temperature figures did not drift from those seen on the previous test point. Risk to the aircraft and crew can also be mitigated if there is a procedure for rapidly restoring the engine under test and the ‘failed’ engine to full performance if needed. This may involve detailed discussions with the manufacturer and could lead to a non-standard engine handling methodology. Of equal importance is to have a single command such as ‘Abort!’ which can be issued by any member of the crew, or the observer in telemetry, to restore the engines and achieve a safe flight condition. Finally if cockpit controls have been used to limit an engine then the nonflying crew member keeps his or her hands on the relevant engine controls at all times.

OEI testing for civil procedures is in many respects the same as for military requirements, however, the aims of the test programme are slightly different and this is particularly true for the take-off and landing phases of flight. In military operations it is accepted that the aircraft may spend periods where an engine failure would place the aircraft at risk. The results of testing are therefore used to determine the level of risk for a typical mission. In addition information is produced which lets the operational pilot know where the risk lies (the height/velocity diagram) and which techniques can be used to avoid or minimize damage if a failure does occur. The military pilot can then make an informed judgement on how the aircraft should be operated. Civil operations have a different philosophy. When operating to JAR-29 Category A requirements [7.11] there is an intention that passengers are not placed at significant risk in the event of any failure including the powerplants. The overall aim of the civil OEI test programme then is to determine the boundaries of safe operation. This is achieved by establishing limiting combinations of AUM and density altitude at which passenger safety is assured provided the pilot performs the reject or flyaway in the prescribed manner. The estimation must include a suitable delay time to account for pilot recognition of a failure of the most critical engine (JAR-29.55 and 29.77). It

|

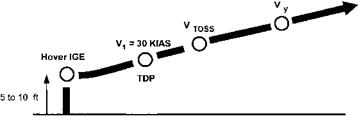

Fig. 7.15 Normal take-off – JAR Category A requirements. |

|

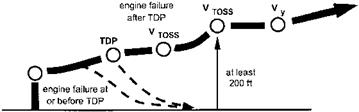

Fig. 7.16 Engine failure during take-off – JAR Category A procedures. |

is worth examining the way that civil operators deal with the two most critical flight phases – take-off and landing.

Figure 7.15 shows a typical technique for conducting a normal take-off under Category A conditions. From a low IGE hover, with the height set such that following an engine failure the aircraft could descend vertically at a rate below the limit for the landing gear, the pilot applies take-off power and starts a climbing acceleration. The take-off decision point (TDP) is usually reached when the aircraft is slightly higher and has positive airspeed indications, typically 30 KIAS. The TDP is defined as the first point from which a continued take-off is assured and the last point from which a rejected take-off is assured within a specified distance (JAR-29.55). Different take-off techniques are often prescribed for different scenarios: short runways, confined areas or helipads and it is common practice for a manufacturer to specify a reduction in the maximum permitted AUM and HD as the take-off area gets smaller and more congested. Once the TDP has been passed the aircraft is accelerated to take-off safety speed (ETOss) and then on to the speed for best rate of climb (Vy).

Figure 7.16 shows a typical flight path for an engine failure before or at the TDP and for a failure after the TDP in VFR conditions. In the first case an aborted takeoff is performed by reducing speed and landing on. For a failure after the TDP the aircraft is quickly accelerated to achieve VTOSS. This speed is then held until the height has increased to at least 200 ft (JAR-29.59) before the speed is increased to Vy.

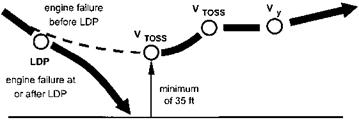

The approach to landing is treated in a similar way. In Fig. 7.17 flight paths for an engine failure either side of the landing decision point (LDP) are depicted. The LDP is the last point in the approach and landing path from which a baulked landing can be performed (JAR-29.77). During the aborted approach the aircraft may not descend below 35 ft at any time.

For both take-off and landing under Category A flight the civilian pilot is required

|

Fig. 7.17 Engine failure during landing – JAR Category A procedures. |

to consult the aircraft flight manual to determine the aircraft performance. As indicated above the information is likely to include:

• maximum permissible take-off and landing weights;

• rate of climb with one engine inoperative;

• the acceleration/stop distance;

• distance to clear a 50 ft obstacle with an engine failure at the TDP;

• landing distance for an engine failure after the LDP.

The aim of civilian OEI testing is to determine the optimum technique and combination of heights AGL and speeds for conducting these take-offs and landings. In addition the helicopter performance will be noted so that the appropriate information regarding maximum weights can be presented in the flight manual. The test procedures used are closely related to those that have already been covered, however, a more detailed examination of the techniques used to determine the TDP is worthwhile.

For establishing the TDP the critical engine is ‘failed’ at a height and speed which allows the 35 ft minimum height to be respected easily. The height and speed are then incrementally reduced until either the TDP predicted by a model is reached or the minimum 35 ft ground clearance is just achieved. It is worth reiterating the ‘golden rule’ that only one parameter should be varied at a time. The next stage is to conduct a series of aborted take-offs starting at low height and speed and incrementally working towards the TDP established from the previous tests. It is mandated (JAR – 29.55) that the TDP is easily recognizable by the pilot in terms of height and/or speed. Using speed alone can often be problematical due to the poor performance of most pitot systems at low speeds.