Cricket balls

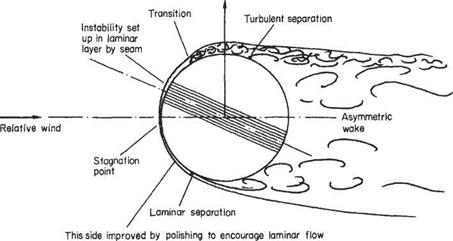

The art of the seam bowler in cricket is also explainable with reference to boundary – layer transition and separation. The bowling technique is to align the seam at a small angle to the flight path (see Fig. 7.20). This is done by spinning the ball about an axis perpendicular to the plane of the seam, and using the gyroscopic inertia to stabilize this seam position during the trajectory. On the side of the front stagnation point where the boundary layer passes over the seam, it is induced to become turbulent before reaching the point of laminar separation. On this side, the boundary layer remains attached to a greater angle from the fore stagnation point than it does on the other side where no seam is present to trip the boundary layer. The flow past the ball thus becomes asymmetric with a larger area of low pressure on the turbulent side, producing a lateral force tending to move the ball in a direction normal to its flight path. The range of flight speeds over which this phenomenon can be used corresponds to those of the medium to medium-fast pace bowler. The diameter of a cricket ball is between 71 and 72.5 mm. In air, the critical speed for a smooth ball would be about 75 m s_I. However, in practice it is found that transition to turbulence for the seam-free side occurs at speeds in the region of 30 to 35ms’1, because of inaccuracies in the spherical shape and minor surface irregularities. The critical speed for a rough ball with early transition (Re ю 105) is about 20ms_I and below this speed the flow asymmetry tends to disappear because laminar separation occurs before the transition, even on the seam side.

Thus within the speed range 20 to about 30 m s_1, very approximately, the ball may be made to swing by the skilful bowler. The very fast bowler will produce a flight speed in excess of the upper critical and no swing will be possible. A bowler may make the ball swing late by bowling at a speed just too high for the asymmetric condition to exist, so that as the ball loses speed in flight the asymmetry will develop later in the trajectory. It is obvious that considerable skill and experience is required to know at just what speed the delivery must be made to do this.

It will also be realized that the surface condition, apart from the seam, will affect the possibility of swinging the ball, e. g. a new, smooth-surfaced ball will tend to

|

Normal force

|

maintain laminar layers up to separation even on the seam side, while a badly worn ball will tend to induce turbulence on the side remote from the seam. The slightly worn ball is best, especially if one side can be kept reasonably polished to help maintain flow on that side only.