Strain gage transducers

One class of pressure transducers is based on the detection, with a strain gage, of the deformation of a plate (diaphragm) or the deflection of a cantilever beam, subjected to the pressure to be measured.

The strain gage consists of a wire or a ribbon glued, or sometimes deposited under vacuum, to an insulating support. The electrical resistance, R, of a conductive wire is given by

R = pS (1.10)

where p is the resistivity of the conductor, l its length and S its crosssectional area.

Differentiating Equation (1.10), is obtained:

where e and et are the longitudinal and transverse strains, respectively.

The gage factor is the ratio of unit change of resistance and longitudinal strain

gage factor —dR = 1 + 2v + (1.12)

є R ep

where v is the Poisson’s ratio (v = etfє|).

The gage factor for metallic wires ranges between 2 and 5. Since usually the strain gage is one of the resistances of a Wheatstone bridge, the bridge output signal, for a given strain, is proportional to the gage factor.

The sensitivity of a transducer is proportional to the inverse stiffness (compliance) of its flexural element. The compliance, defined as the deflection (Dx) per applied load, of a cantilever beam subjected to an end load, F, is:

— = —mN-1 (1.13)

F 3EI

where E is the Young’s modulus and I is the moment of inertia of the beam’s cross-sectional area.

The compliance of the center of an edge-fixed circular plate to a uniform load p is:

A = 3 (1 – v) r2mN_1 (1.14)

pnr 16л Et

where t is the thickness and r is the radius of the plate.

The natural frequency for the fundamental mode of vibration of a cantilever beam is:

where m is the mass per unit length.

The natural frequency for the first circular mode of vibration of a fixed edge circular plate is:

![]() = 1.6183 I Et3

= 1.6183 I Et3

= r1 ]j12p(1 – v2) Hz

where p is the mass per unit area.

The relationships between flexibility and natural frequencies of vibration are therefore:

If high flexibility is needed to get a strong enough signal, the natural frequency of the element is limited and hence the maximum frequency detectable by the transducer.

Pressure transducers with strain gages of the smallest size (6 mm in diameter) are commercially available with a frequency response of 10 kHz, which are particularly useful in applications where the sensing element can be flush-mounted on a wall so to avoid interference with the stream. They are fairly cheap and easy to manufacture and are robust.

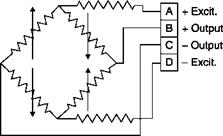

The diaphragm deflection is transmitted to a displacement transducer element which consists of four sets of unbounded wire strain gages

![]()

|

Circuit diagram of a strain gage transducer

forming the four arms of a resistance bridge (see Figure 1.9). A galvanometer, oscilloscope or recording instrument indicates the bridge imbalance arising from changes in the bridge resistances after a strain is imposed on the wire. The galvanometer output is calibrated to yield the pressure indication. The use of four strain elements, two of which are shortened and two of which are lengthened by the diaphragm displacement, increases the instrument sensitivity. These instruments are also supplied with a temperature compensator to eliminate thermal resistance changes and consequent error in the pressure indication.