Rotor Mechanisms for Forward Flight1

4.1 The Edgewise Rotor

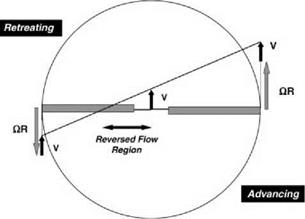

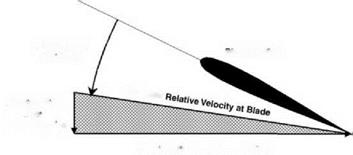

In level forward flight the rotor is essentially edgewise on to the air stream, a basically unnatural state for propeller functioning. This is shown in Figure 4.1. Practical complications which arise from this have been resolved by the introduction of mechanical devices, the functioning of which in turn adds to the complexity of the aerodynamics.

Figure 4.2 pictures the rotor disc as seen from above. Blade rotation is in an anticlockwise sense with rotational speed O. Forward flight velocity is V and the ratio V/OR, R being the blade radius, is known as the advance ratio and given the symbol p. It has a value normally within the range 0.0 to 0.5. Azimuth angle C is measured from the downstream blade position: the range C = 0°-180° defines the advancing side and that from 180°-360° (or 0°) the retreating side.

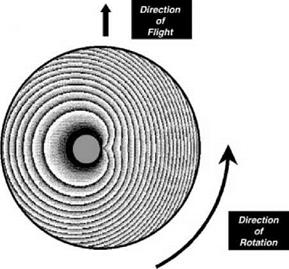

A blade is shown in Figure 4.2 at 90° and again at 270°. These are the positions of maximum and minimum relative air velocity normal to the blade, the velocities at the tip being (OR + V)and (OR—V), respectively. If the blade were to rotate at fixed incidence, then owing to this velocity differential, much more lift would be generated on the advancing side than on the retreating side. Calculated pressure contours for a fixed-incidence rotation with p = 0.3 are shown in Figure 4.3. For this situation, about four-fifths of the total lift is produced on the advancing side. The consequences of this imbalance would be large oscillatory bending stresses at the blade roots and a large rolling moment on the vehicle tending to roll the aircraft towards the retreating side. Both structurally and dynamically the helicopter would be unflyable.

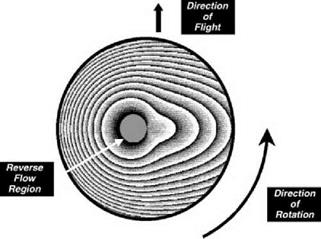

Clearly a cyclical variation in blade incidence is needed to balance lift on the two sides. If we permit the blade pitch to vary sinusoidally as the blade rotates around the azimuth to an amount which balances out the rolling moment of the rotor, the contours of pressure level for this roll – balanced lift distribution are of the type shown in Figure 4.4.

The mean pressure level is now lower, the lift on the advancing side being greatly reduced, with only small compensation on the retreating side. The fore and aft sectors now carry the main lift load. The total lift can be restored in some degree by applying a general increase in blade 1 Portions of this Chapter have been taken from The Foundations of Helicopter Flight by Simon Newman, Elsevier, 1994.

Basic Helicopter Aerodynamics, Third Edition. John Seddon and Simon Newman. © 2011 John Wiley & Sons, Ltd. Published 2011 by John Wiley & Sons, Ltd.

|

Figure 4.1 Main rotor alignment in forward flight |

incidence level through the pilot’s control system (Section 4.3), but as this is performed the retreating blade, which is producing lift at relatively low airspeed, must ultimately stall. In addition, compressibility effects such as shock-induced flow separation must be considered, both on the advancing side where the Mach number is highest and on the retreating side where lower Mach number is combined with high blade incidence. Since the degree of load asymmetry across the disc increases with forward speed, the retreating-blade stall and its associated effects determine the maximum possible flight speed of the vehicle. For the conventional helicopter a speed of about 400 km/h (250 mph) is usually regarded as the upper limit.

While this technique would balance out the overall rolling moment, the rigid connection of the blades to the hub would cause a significant amount of vibratory forcing to be transmitted to the rotor hub and hence to the helicopter. The mechanisms which can avoid this are now described. The widely adopted method of achieving this is by use of flapping hinges, first introduced by Juan de la Cierva around 1923. The blade is freely hinged as close as possible to

|

|

|

Figure 4.3 Pressure contours without roll trim |

the root, allowing it to flap up and down out of the plane of rotation as it rotates about the rotor shaft. The presence of free hinges means that blade root stresses are avoided and no rolling moment is communicated to the airframe. The blades are now under the influence of two types of moments. The lift force is trying to flap the blades upwards by creating a moment about the flapping hinge – moving the blades out of the rotation plane – while the centrifugal force is working in opposition – driving the blades back towards the rotation plane. In hover, the blade position is stable and these two moments cancel out. Figure 4.5 shows a Sikorsky S61NM

|

|

|

Figure 4.5 Sikorsky S61NM helicopter approaching touchdown (coned rotor) |

hovering prior to landing. The rotor blades are ‘coned up’ as the flapping hinges relieve the flapping moment of the lift loads and the two moments are in equilibrium. Figure 4.6 shows the aircraft after touching down where the rotor thrust has been reduced to zero and the rotor disc is now flat, under the influence of the centrifugal effects only (gravity has a small effect which is usually neglected – the main rotor tip experiences centripetal accelerations of 750-1000 g).

As the rotor moves into horizontal flight the situation of Figure 4.2 establishes itself. The incident flow over the blades will depend on their azimuthal position. The blade on the advancing side experiences an increased incident flow and the lift will increase, overcoming the centrifugal moment, so the blade will now flap upwards. As it flaps upwards, a downward flow is superimposed on the blade and the lift will reduce. See Figure 4.7. This continues until the blade flaps to its highest position. The reverse effect occurs for the blade on the retreating side where the blade will flap downwards to its lowest position. The maximum velocity change is at the 90° and 270° azimuth. It will be shown that the extreme blade flapping angles are achieved very close to 90° of blade rotation around the azimuth. The result is that the blades will flap up at the front of the rotor and down at the rear and the disc will tilt rearwards. It is normally accepted that the thrust force is aligned with the normal to the rotor disc. We have the situation where the rotor thrust is now inclined rearwards and forward motion is not possible. In order for the rotor to supply forward propulsion, the rotor disc must be tilted forwards, directly opposing the natural effect of blade flapping. This can only be achieved by altering the blade lift through a pitch change. This is known as cyclic pitch and will be discussed later.

|

Figure 4.6 Sikorsky S61NM helicopter after touchdown (flat rotor) |

Relative Wind from Forward Flight

Relative Wind from Forward Flight

Figure 4.7 Incident velocity components

This pitch angle movement is provided by a pitch bearing, known alternatively as the feathering hinge, linked to a control system operated by the pilot (Section 4.3).

An additional feature of the asymmetry in velocity across the disc is that there exists a region on the retreating side where the flow over the blade is actually reversed. At 270° azimuth the resultant velocity at a point r of span is:

![]()

U = O r-V

or non-dimensionally:

Thus the flow over the blade is reversed inboard of the point x = m. It will be apparent that the reversed flow boundary is a circle of diameter m, centred at x = m/2 on the 270° azimuth. Dynamic pressure in this region is low, so the effect of the reversed flow on the blade lift is small, usually negligible from a performance aspect for advance ratios up to 0.4. Very precise calculations may require the reversed flow region to be taken into account and it may be important also in studies of blade vibration. Some advanced rotor concepts have required the rotor rotational speed to be reduced, even halted. This will cause the reversed flow region to become a significant part of the rotor disc.

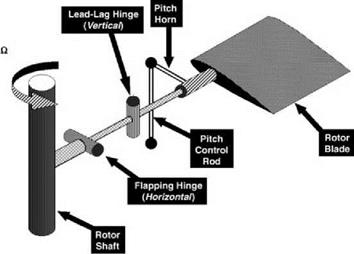

A flapping blade in rotation sets up Coriolis moments in the plane of the disc, and to relieve this it is usual to provide a second hinge, the lead-lag hinge, normal to the disc plane, allowing free in-plane motion. This may need to be fitted with a mechanical damper to ensure dynamic stability.

The standard articulated blade thus possesses this triple movement system of flapping hinge, lead-lag hinge and pitch bearing in a suitable mechanical arrangement, located inboard of the lifting blade itself. The principles are illustrated in Figure 4.8.

Kaman aircraft use a slightly different system where blade pitch is controlled by a trailing edge servo flap. This is deflected by the pilot’s controls, which generates a moment causing the blade to elastically bend in pitch. These servo flaps can be seen in Figure 4.9 which shows the KMax while Figure 4.10 shows the Seasprite.

|

Figure 4.8 Principles of an articulated rotor hinge system |

|

|

|

Figure 4.10 Kaman Seasprite (Courtesy US Navy) |

Strictly the blade root bending stress and helicopter rolling moment are eliminated by flapping only if the hinge is located on the axis of rotation. This is impracticable for a rotor with more than two blades, so residual moments do exist. These are not important, however, if the offset of the hinge from the axis is only a few per cent of blade radius – which is normal. The flapping hinge is therefore normally made the innermost, with an offset of 3-4%. The lag hinge and pitch bearing can be more freely disposed: sometimes the former is the farther out of the two. The order of the hinges has a significant effect on the blade dynamic behaviour and if the pitch bearing is placed inboard of either or both of the flap and lag hinges, kinematic couplings can be generated.

The total mechanical complexity of an articulated rotor is substantial. Hinge bearings operate under high centrifugal loads, so service and maintenance requirements are severe. Hinges, dampers and control rods make up a bulky rotor head, which is likely to have a high parasitic drag – perhaps as much as the rest of the helicopter.

In modern rotors, the flapping and lag hinges are often replaced by flexible elements which allow the flapping and lead-lag motions of the blades to take place, albeit with a degree of stiffness not present with free hinges. With such hingeless rotors, bending stresses and rolling moments reappear, in moderation only but sufficient to modify the stability and control characteristics of the helicopter (Chapter 8). The effect of a flexible flapping element can usually be calculated by equating it to a hinged blade with larger offset (10-15%). The use of a hingeless rotor is one way of reducing the parasitic drag of the rotor head. A pitch bearing mechanism is of course needed for rotor control, as with the articulated rotor. The hingeless rotor of the Agusta Westland Lynx helicopter is pictured in Figure 4.11.