Control Surface Buzz

Control surface buzz is properly a single-degree-of-freedom flutter phenomenon, and thus not in the stability and control domain, but its cures affect controllability. Buzz was first encountered in dives on the Lockheed P-80 Shooting Star. Pilots reported strong, high-frequency lateral shaking of the control stick. Ordinary flutter was ruled out because calculations showed a reasonably high coupled wing-aileron flutter speed. The P-80’s wing is stiff, with 13-percent-thick NACA 65-series airfoils, and the ailerons are mass balanced. Moreover, the vibration frequency was higher than would be expected for structural modes.

The cause of the shaking turned out to be an aileron-alone mode, not involving wing bending or torsion at all. At Mach numbers where wing normal shocks perpendicular to the fuselage are in the vicinity of the aileron hinge line, shock position couples with aileron deflection to produce the motion. Trailing-edge-upward deflection of the aileron causes flow field changes that move the upper wing surface normal shock forward and the lower wing surface normal shock aft. This causes relative trailing-edge-down hinge moment, starting the aileron down and eventually reversing the shock wave upper and lower surface positions. This completes the cycle.

Clearly, control system flexibility plays a role in aileron buzz, permitting symmetric or in-phase aileron deflections. Restraining the aileron from symmetric rotations prevents buzz. The F-80’s control surface boost cylinder is on the airplane’s centerline. Control system flexibility from the centerline out to the ailerons is sufficient for buzz to occur.

The buzz fix for the P-80 and later airplanes with centerline aileron actuators was rotary hydraulic dampers installed at each aileron hinge. Damping is approximately proportional to control surface angular velocity, which is very high during high-frequency buzz but much lower for normal stick motions. Properly sized buzz dampers do not interfere with lateral controllability. Modern jet airplanes normally have irreversible hydraulic actuators located at each aileron. Aileron buzz is not a possibility for this arrangement.

Control surface buzz was a problem for the rudders of two subsonic jet airplanes of the 1950s, a late-model North American F-86 Sabre and the Douglas A4D Skyhawk. Both airplanes used splitter-plate or “tadpole” rudders to overcome buzz. Splitter-plate control surfaces are unskinned from about the midchord to the trailing edge, with loads borne by a central or splitter plate. The normal shock, whose fore and aft motion is central to control surface buzz, is stabilized at the abrupt surface break where the splitter starts. Another

|

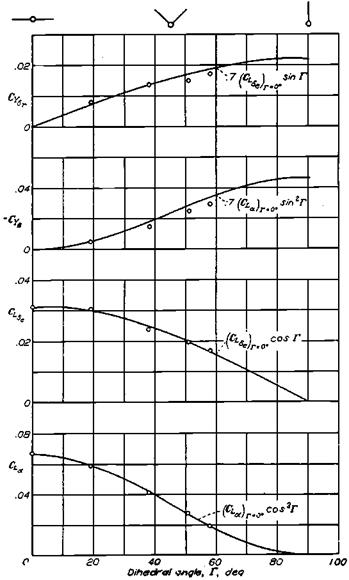

Figure 14.12 Experimental verification (small circles) for the Purser/Campbell vee-tail theory. Isolated tail stability and control contributions are plotted against tail dihedral angle. (From Purser and Campbell, NACA Rept. 823, 1945) |

aerodynamic fix for control surface buzz is reported to be the addition of vortex generators just ahead of the control surface hinge line.