The effect of altitude on the drag curve is very similar. As the altitude increases the density is reduced and this can be compensated by an increase in cruising speed to keep the dynamic pressure constant. If the aircraft attitude is kept constant both lift and drag coefficients will remain constant as before, and the drag curve will be shifted to the right in exactly the same way as before (Fig. 7.5).

Maximum speed

The maximum speed in level flight that can be attained by the aircraft can be deduced very simply from Fig. 7.4. In order to achieve the maximum speed we need the intersection between the drag and engine thrust curves to be as far to the right as possible. This is clearly obtained when the engine is at the maximum throttle setting.

This seems to be a very simple situation, but a word of caution is necessary. We have assumed a comparatively simple form for the drag curve in our discussion. Compressibility effects may have an important influence on this for a particular aircraft. Such factors as the buffet boundary (Chapter 9) may then limit the maximum speed. High speed aircraft may also be limited by the maximum permissible structural temperature, which may be approached due to kinetic heating effects (Chapter 8). These factors may restrict the permitted maximum to a value below that which would be suggested by the simple ‘available thrust’ criterion. Additional limitations may be imposed by the constraints on the engine operating conditions (Chapter 6).

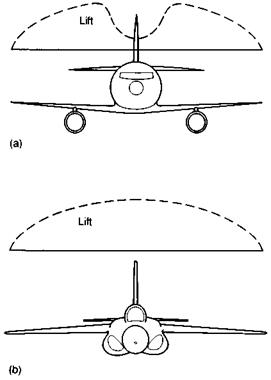

Increasing the wing loading has the primary effect of shifting the whole of the drag curve to a higher speed (Fig. 7.5) without increasing the drag itself. Therefore a high wing loading, and consequently small wings, is desirable from the point of view of obtaining high speed.

A similar argument might lead the reader to suppose that high altitude is also desirable for high speed. To some extent this is true but it must be remembered that increase in altitude implies a reduction in temperature, and thus a lower speed of sound. This means that the flight Mach number will be increased for a given air speed at high altitude. Compressibility effects will therefore be apparent at a lower air speed and this will impose an important restriction, particularly for aircraft designed for operation at subsonic or transonic speeds.