The step input is a popular method of determining the control response characteristics of a helicopter. It involves trimming the rotorcraft in to the hover or in straight and level flight at a given airspeed and then making a pure step input using the appropriate control inceptor. In forward flight, pitch and roll inputs are made, whereas in the hover due to the differing response characteristics it is possible to make yaw inputs as well. Test data can be gathered in a rudimentary fashion using manual techniques although it is commonplace to use either on-board automatic data recording or telemetry as the primary data source. With this in mind, the test technique has evolved to one that maintains flight safety by using manually recorded data, regardless of the on-board or telemetry system adopted, to ensure an incremental increase in the severity of the aircraft manoeuvre. This method also allows factoring of pilot opinion on the difficulty of recovery into the choice of the next increment to test.

Since most unaugmented helicopters will achieve steady rates within two seconds of the input being made it is usual to hold it for the count of two and then initiate recovery. In this way the recovery action becomes part of the test and the pilot will automatically restore the aircraft to the trim condition at the end of the count unless, of course, a self-declared limit is likely to be transgressed beforehand. Control response testing using step inputs can be conducted in a low-risk, incremental manner provided a set routine is performed The routine adopted at ETPS, shown in Table 5.1, is an example of the recommended methodology. Whatever the precise routine adopted, test teams must treat changes to the direction of input with great care. There is always the possibility that having made several aft inputs the pilot will have so conditioned himself that he pulls the control inceptor aft even though the next test point requires a movement forward!

A control fixture, see Fig. 5.9, is a common means of ensuring that a step input of a pre-determined size is made. The fixture provides a rigid surface against which the control inceptor may be held thereby enabling pure step inputs. The requirements of flight safety normally require that the fixture be held in place manually by a flight test observer situated at the co-pilot station. Consequently this test method can only be used on helicopters fitted with dual controls. Alternatives to the fixture include injecting discrete control inputs via the automatic flight control system. Care is taken to avoid off-axis inputs (the introduction of lateral cyclic during longitudinal control

|

Table 5.1 Control response testing.

|

Non-handling pilot or observer

|

Handling pilot

|

|

Trim aircraft to required flight condition ‘On condition’

|

|

Sets fixture for next input size ‘ The next input will be 1 cm aft’ Appropriately orientates fixture and shows fixture to pilot

|

Glances at fixture ‘ Confirmed’

|

|

Positions fixture next to control inceptor

‘In position’

|

‘Stand by for a 1cm aft input on the count of three, are you ready’

|

|

Checks that fixture is still in place and correctly orientated ‘Ready’

|

Glances across the cockpit to ensure that fixture is correctly orientated

|

|

Notes actual input size and whether input held against fixture

|

‘1001, 1002, 1003 – moves inceptor – 1004, 1005, recovering’

Notes attitude at 1004 and 1005

|

|

Plots attitude at 1 and 2 seconds against input size on ‘how-goes-it’ chart, chooses next input size

|

Restores aircraft to required flight condition and reads back attitudes

|

|

|

Fig. 5.9 A control fixture.

|

response testing for example). Using only the hand or fingers to make the input rather than moving the whole arm can facilitate this. The control is held rigidly against the fixture until the desired results have been achieved or recovery is necessary. A buildup technique is employed using progressively larger inputs so that the testing can be terminated early should any untoward trends develop. Control cross-coupling may be evaluated by observing the response in other axes. The use of telemetry or a near real-

|

Fig. 5.10 Definition of control response parameters.

|

time display of input shape is often used so that a poor input shape can be recognized quickly and the test condition repeated immediately.

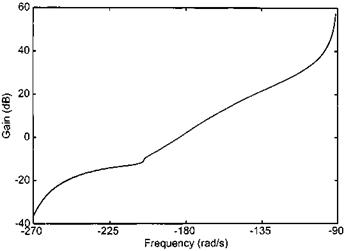

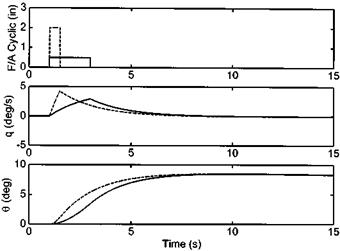

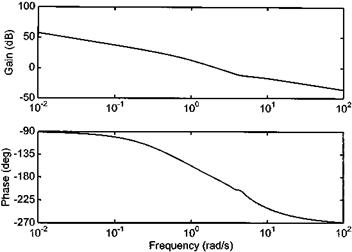

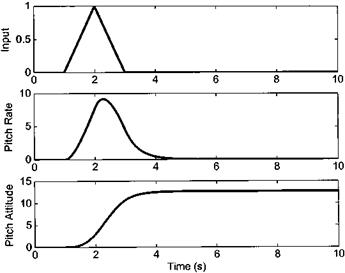

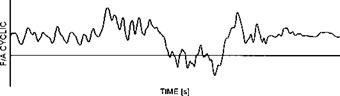

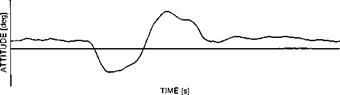

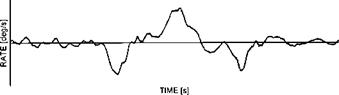

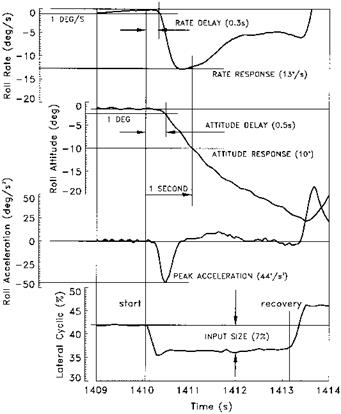

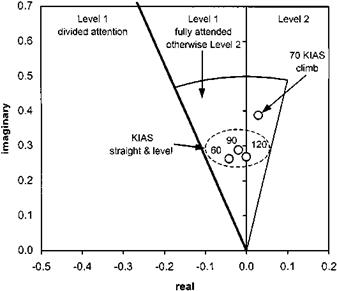

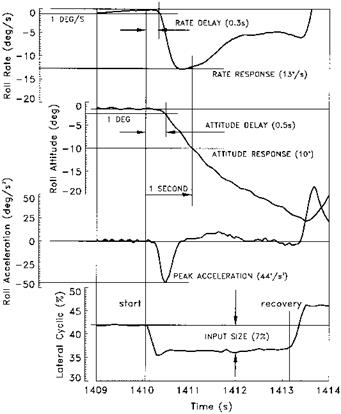

The control response characteristics of a rotorcraft are characterized using a standard set of control response parameters, see Fig. 5.10. These parameters are based on the assumption that the helicopter has a first-order rate response to control inputs. The attitude and rate responses are, respectively, the aircraft attitude and angular rate achieved one second after the input. The attitude and rate delay quantify the time taken for the helicopter to change attitude by one degree and generate an angular rate of one degree per second. The steady-state rate and peak angular acceleration are selfexplanatory. A useful parameter for comparing the control response of different helicopters is the control sensitivity, which is the maximum angular acceleration achieved for a standard input size (1 cm or 1 inch).

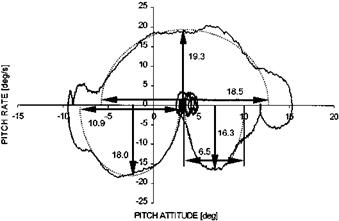

Figure 5.10 highlights a typical problem in estimating steady-state angular rates. Due to the effect of sideslip it is unusual for rotorcraft to acquire a steady roll rate. Since the magnitude of the steady-state rate is only used in comparison with the rate response to judge the crispness of the control response, this phenomenum does not usually present the test team with much of a problem. In the figure it is clear that the aircraft reaches a peak rate within one second. This peak rate approximates to the

steady rate that would have been acquired if the helicopter truly behaved as a first – order system. Therefore the steady rate and rate response can be stated as being equal and the control response characterized as ‘crisp’.

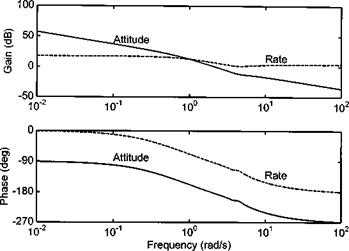

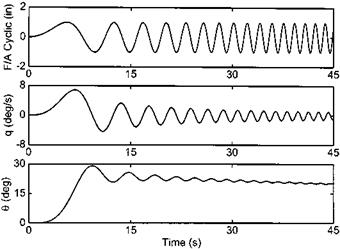

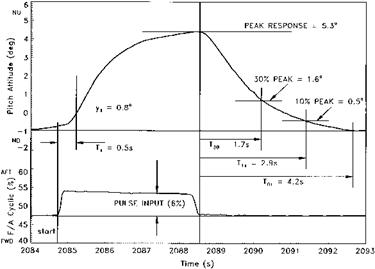

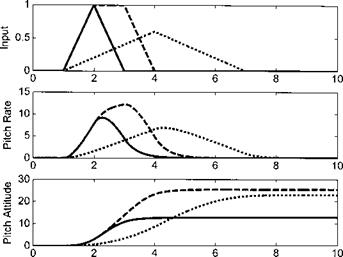

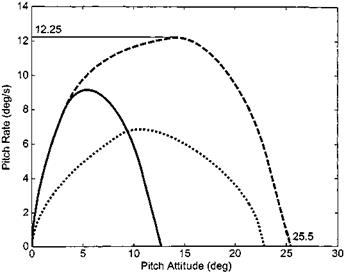

Having gathered a set of traces and analyzed them in the manner shown in Fig. 5.10 it is possible to construct a set of summary charts to portray the control response characteristics. There are two categories of derived plots that are used to summarize control response data. One is the variation of control response parameters with airspeed: any or all of the control response parameters (rate response, attitude response, control sensitivity, steady-state rate) may be plotted against airspeed for a given input size. Alternatively the variation of control response parameters with input size for a given flight condition may be presented, see Fig. 5.11. In each case the pilot would expect some progression in response. For example, at a given speed a larger input should yield a larger, ideally proportional, response, whereas the pilot would expect a given input size to yield a larger response at a higher speed. An abundance of quantitative data can be taken from response time histories. In discussing control response it is important that the parameters chosen and presented support the pilot’s qualitative opinion. Parameters that define the ‘amount’ of the control response are

Fig. 5.11 Control response test data.

the rate response, the attitude response, and the steady-state pitch rate. Quantities which can be used in discussing the quality of the response or ‘how’ it got to the observed steady-state rate are the delay time, the initial angular acceleration, the time to steady state, and the inflection time.

When conducting manual step response testing there are several flight safety points to consider. Ideally visual confirmation of the input size (fixture setting) and input direction should be made before commencing the cadence count. Although this is easy to accomplish in a side-by-side cockpit, the test team will need to consider carefully how this might be achieved in a rotorcraft with a tandem cockpit configuration. Modern attack helicopters tend to have the cockpit stations optimized for pilot and co-pilot/gunner. This usually involves differences to the control inceptors in terms of location, force-feel and possibly gearing (the AH-1 Cobra is a good example). Such differences require careful consideration when establishing the procedure for in-flight testing. In addition to using an in-flight plot or ‘how-goes-it’ chart to track the approach to a limiting parameter, other visual indicators can be used. Large cyclic control deflections will typically reduce the clearance between the main rotor tip-path plane and the fuselage. An appropriately located set of ‘chicken-sticks’, see Fig. 5.12, which are designed to break if struck by a rotor blade, can warn of impending mishap. Ideally such devices will be located within the pilot’s field of view so that he can confirm easily if the clearance has reduced to hazardous dimensions. Should this not be possible then the sticks are modified to include an electric circuit that will illuminate a suitable warning lamp in the cockpit if they are broken. The development of small proximity sensors of suitable accuracy has enabled a more sophisticated approach giving a greater range of information and warning.

Step response testing may require the employment of large inputs that could lead to aircraft damage if performed without due care. The following additional precautions are typical of those adopted to minimize this risk:

Fig. 5.12 ‘ Chicken-sticks’.

• Awareness of the effects of manoeuvre instability during aft inputs that may lead to an unexpected ‘dig-in’ and possible overstress of the airframe or rotor system.

• Careful monitoring of the approach to limitations and the use of an appropriate ‘how-goes-it’ chart.

• Anticipation of possible series actuator saturation and a consequent sudden increase in aircraft response when testing augmented aircraft.

• Careful briefing and practise to ensure that the entire crew is aware of the control input size, direction and recovery action.