Transient droop and overswing

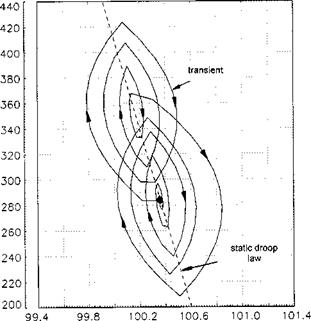

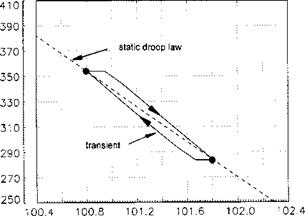

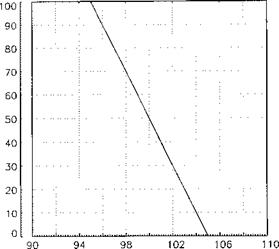

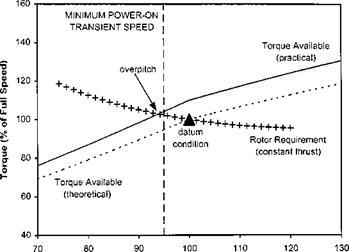

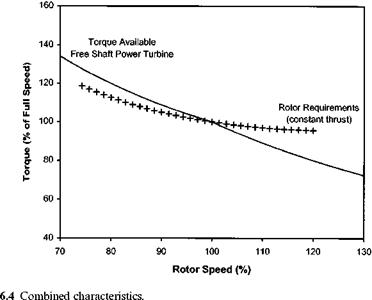

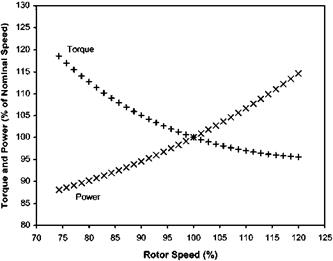

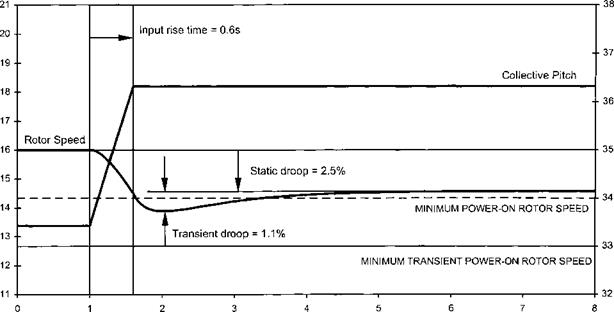

Transient droop or overswing is the variation in RRPM that occurs during changes in power initiated by a movement of the collective lever. Usually during an increasing torque demand there will be a rotor underspeed and during a power reduction the rotor will overspeed. Changes in NR occur because, in general, engine acceleration or deceleration cannot match the rates of change of collective pitch. Therefore during, say, power increases there will be a finite delay between the power demand (changed collective position) and the required power being produced (the gas generator reaching a new speed). During this delay the RRPM will fall to a figure which is below the steady state static droop for the new power. This extra reduction in RRPM is defined as the transient droop, see Fig. 6.9.

The delay is aggravated by the fact that a rotor speed error must develop before the gas generator will begin to accelerate. Eventually, just as with static droop, the transient droop may be large enough to put the RRPM outside its aerodynamic or mechanical limits. Without further modification of the control system, the only way of overcoming this is to limit the rate of collective pitch movement. This means in practice that the manoeuvrability of the helicopter is limited, and indeed some early machines were affected in this way. Other factors which affect the size of the overswing or droop are:

• governor gain;

• inertia of the main rotor;

• helicopter AUM;

• density altitude;

• acceleration and deceleration characteristics of the engine.

|

|

|

|

|

|

|

|

|

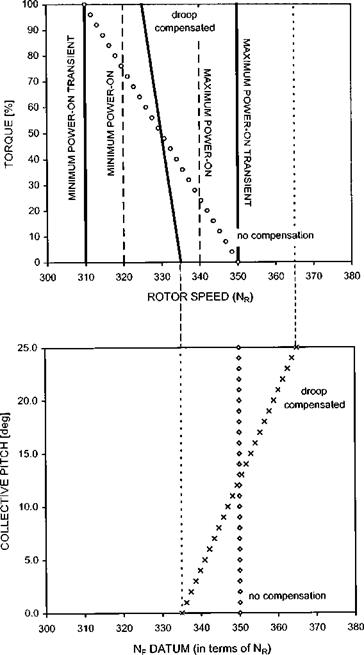

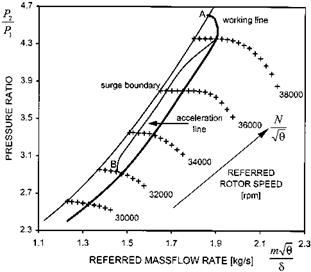

Consequently rapid acceleration is a basic design requirement of modern helicopter engines. Two factors help to make rapid acceleration possible: low rotational inertia and high idle speeds (typically flight idle = 70% of maximum NG), which helps the engine tolerate a large degree of overfuelling. Alternatively, as discussed, a droop anticipator or compensator can be fitted which has the added benefit of reducing transient droop since it will start the gas generator accelerating without having to wait for a RRPM error. A further refinement is the generation of a signal proportional to the rate of change of collective. This signal is then used to open or close the gas generator throttle, depending on whether the collective is increasing or decreasing, so that the gas generator RPM starts to alter as soon as the collective is moved. Some fuel control systems are also configured with yaw pedal anticipator inputs.