Best speed for economy and range

As we mentioned earlier in this chapter, the ‘best’ operating speed for an aircraft depends on the particular role it is designed to fulfil. If the object of the exercise is to carry passengers from A to B, then an important consideration is the amount of fuel used, which will normally be kept close to the minimum for the job in hand. Achievement of maximum range is a very similar problem. In this case instead of having a requirement to travel a fixed distance using the minimum amount of fuel, we need to travel the maximum distance for a given fuel load.

If we take a very simplified view of things, and assume constant engine efficiency, the requirement, both for best range and economy, is that the total amount of work done as the aircraft moves from A to B should be kept as low as possible.

The total work done is the force times the distance through which it is moved. In this case the only force which is moved through a significant distance is the drag (Fig. 7.6) and the distance through which it is moved is equal to the distance the aircraft flies between its starting and stopping points. Thus, we can see that for the best economy, on this simplifed view, the aircraft should be

|

Fig. 7.6 Economic cruise Total energy expended as aircraft flies from A to B is equal to the drag times distance flown |

flown at its minimum drag speed. It should be noted that this speed will change during the flight as the aircraft weight will reduce as fuel is used up.

Approximately at least, changes in wing loading and altitude only alter the speed at which the minimum drag occurs and not its value. Thus as far as the airframe is concerned the total energy which must be expended for a given journey is independent of both wing loading and altitude.

We know from Chapter 6 that in reality engine efficiency is not constant and that the different types of powerplant have their distinctive characteristics. Consequently we shall consider the problems of operating the complete air- frame/engine combination for optimum economy under headings appropriate to the type of installed powerplant.

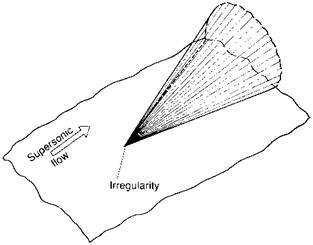

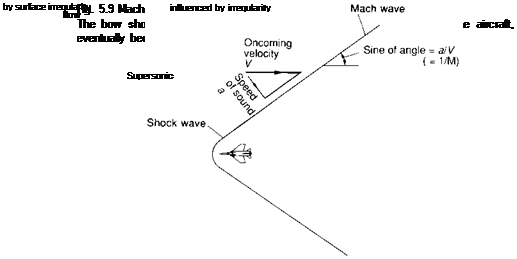

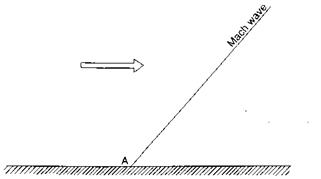

Flow behind Mach wave

Flow behind Mach wave