Test personnel have a large range of tools to document and analyze aircraft characteristics but it should always be borne in mind that it is the performance of the aircraft in the mission that is the most important part of any test programme. It is only by using a test pilot with recent experience of the role and by flying representative tasks that all deficiencies can be identified. This requires the test programme to include sufficient role tasks to be flown in an environment which is as close as possible to the conditions that will be found in service. Good test teams have always understood this concept and in recent years attempts have been made to formalize the process.

5.7.1 Handling qualities rating scales

One of the main functions of the test pilot is to report his or her opinion of the handling qualities of the aircraft after a flight. It is this opinion which will often lead to major decisions being made about a programme and, being an opinion, it is of course entirely subjective. As flight test became a more disciplined science in the period following World War Two it became apparent that some way had to be found to standardize the way in which pilots reported their qualitative results. This was needed so that comparisons could be made between the opinions of different pilots. A number of different approaches were made to try to solve this problem such as the Cornell Aeronautical Laboratory and original Cooper scales. Problems were found with these early attempts and in 1966 Messrs Cooper and Harper presented a joint paper [5.7] to the Flight Mechanics panel of AGARD in which they advocated a ten-point handling qualities rating scale. This Cooper-Harper HQR scale, as it became known, has found wide acceptance in the flight test community and is now the standard way for test pilots to report their opinions of handling qualities. Although the HQR scale is the most widely used type of scale in test flying it is not the only one. Other scales have arisen to quantify a variety of subjects such as workload (the RAE Bedford workload scale); and precise manoeuvres (the A&AEE deck landing scale).

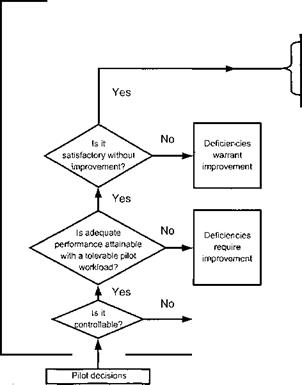

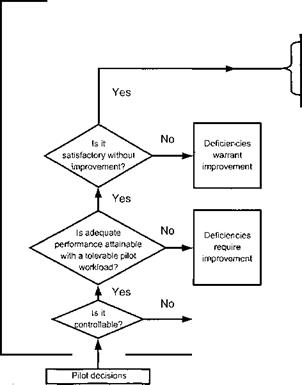

The Cooper-Harper scale is shown in Fig. 5.26 and although it is a relatively straightforward concept it requires a considerable degree of care and skill to apply correctly. The test pilot is presented with three dichotomous questions which when answered lead to four possible categories of quality. Three of these categories are further divided into sub-categories, each of which is awarded a numerical value leading to a total of ten possible HQR values. In essence the HQR scale quantifies the amount of physical or mental compensation that a pilot has to expend in performing a defined task to a defined standard. In this context the term compensation is taken to mean the additional pilot workload required to complete a task, over and above that which would be required when flying an aircraft with excellent qualities. The important phrase here is additional pilot workload; to complete any task will require a certain level of workload even with optimum handling qualities. Cooper and Harper make this clear by stating that the total workload is comprised of the workload due to compensation for aircraft deficiencies plus the workload due to the task itself. The scale was not intended to be linear and therefore it is vital that the pilot enters the scale at the correct point to answer the questions and does not try to shortcut the process by simply choosing a number. This flow chart style of presentation, as shown

Aircraft Demands on the pilot in

Aircraft Demands on the pilot in

characteristics selected task or required operation

Pilot compensation not a factor for desired performance

Pilot compensation not a factor for desired performance

Minimal pilot compensation required for desired performance

|

1

|

r

|

Minor but annoying

|

Desired performance requires moderate

|

A

|

|

|

deficiencies

|

pilot compensation

|

|

|

J

|

1

|

Moderately objectionable

|

Adequate performance requires considerable

|

5

|

|

1

|

1

|

deficiencies

|

pilot compensation

|

|

|

1

|

Very objectionable but

|

Adequate performance requires extensive

|

6

|

|

|

tolerable deficiencies

|

pilot compensation

|

|

Major deficiencies

|

Adequate performance not attainable with maximum pilot compensation. Controllability not in question

|

|

Major deficiencies

|

Considerable pilot compensation is required for control

|

8

|

|

Major deficiencies

|

Intense pilot compensation is required for control

|

9

|

in Fig. 5.26, reinforces this point. Correct use of the scale depends on the evaluator understanding the precise meaning of certain key words which will be explained.

As the HQR is awarded for performing a task it is essential that the task is chosen with care to be relevant to the role of the aircraft. It must be a flying task, of relatively restricted scope, which the pilot must complete in pursuance of the mission. The choice of task is an important stage in the process of assigning an HQR and needs careful consideration. The task must be a distinct phase of flight that can be allocated a definable level of performance. Examples of tasks could be capturing an angle of bank or maintaining a set aircraft attitude and heading. Where a more complex task is being evaluated it may be divided into sub-tasks each of which can be allocated a rating. The highest numerical rating awarded for a sub-task then defines the rating for the task as a whole.

Particularly important terms are workload and performance. Performance can be thought of as the degree of accuracy required from the rotorcraft to execute a task, for example, maintaining the aircraft heading within 10° of the initial value. As the accuracy required increases, a corresponding increase in pilot workload will be needed. This workload can be physical, in terms of control activity and/or mental, in terms of concentration. The workload required to perform the task must be considered in the context of the mission and must take into account the amount of spare mental or physical capacity the pilot would have under operational conditions. This is an important point which is sometimes overlooked. By employing an unrealistically high workload pilots can often achieve very high standards of task performance despite poor aircraft handling qualities. It may be useful to artificially reduce the pilot’s capacity for aircraft stabilization in order to simulate the demands of the mission.

Since workload will depend on the amount of precision required, it is clearly vital that not only the task itself is defined precisely but also the level of performance should be stated, for example, maintaining airspeed during a ground controlled approach to within 5 knots. This task performance is often termed the tolerance and is defined for two levels; desired performance and adequate performance. Performing the task to desired performance indicates that the pilot has been able to achieve the accuracy that he or she would wish for, whereas adequate performance means that a level of accuracy has been achieved which, although below the standard the pilot desires, is sufficient to complete the task. Deciding on the tolerances is probably the most difficult aspect of assigning HQRs and must be approached with care. The tolerance must be applicable to the role and the test pilot must be able to justify the resulting level of accuracy. For example, a desired tolerance to maintain airspeed to within 2 knots during transit flight could probably be achieved but there is unlikely to be any operational justification in setting such a high standard of performance. Setting a very wide tolerance that is unrepresentative of the role requirements would be equally incorrect.

The Cooper-Harper scale allows the performance associated with a particular task to be placed into one of four categories: [11]

• Inadequate performance. This third category is defined by the failure to achieve even the adequate performance despite the pilot workload being increased to the maximum tolerable level in an effort to compensate for handling deficiencies. An improvement in handling qualities is required (HQR 6-9).

• Loss of control. The final category allows for the possibility of loss of control during the execution of a task. An improvement in handling qualities is obviously mandatory (HQR 10).

A term which is often used in specification documents such as 00-970 [5.1] and ADS-33E [5.2] is the handling qualities level. Handling qualities Level 1 encompasses HQR 1-3, Level 2 takes in HQR 4-6 and Level 3 is for HQR 7-9. There is also a direct relationship between the HQR awarded and the pilot’s conclusion on the characteristic under investigation. Thus a satisfactory conclusion could not be supported by an HQR 4 or greater. The question of whether or not half ratings can be awarded is often debated. Cooper and Harper themselves did not disallow this in their original paper. In many test establishments, however, the practice is discouraged at least for aircraft release purposes. One common exception is the use of an HQR 41. This is often permitted to address the large gap between the desired performance with moderate compensation of an HQR 3 and the adequate performance with considerable compensation of an HQR 5. Of course HQR 31 and 61 are never allowed as they sit on the boundaries of the handling qualities levels.

A special case arises when considering failure modes. When applying a rating to an aircraft’s handling qualities following a failure, the likely operational requirement has to be defined. Thus if the aircraft will be required to continue with its mission then an HQR should be applied in the normal way. However, if the aircraft will only be required to return to base and perform a landing then more relaxed tolerances can be applied. It may be that a significant pilot workload results following a failure, for example, landing in manual control after a loss of hydraulic pressure. In this case an HQR 5 might be awarded which would normally be associated with an unsatisfactory conclusion. However, the test pilot might conclude that the aircraft was satisfactory because the high workload might only be required for a short period when full attention can be given to completing the task. In this special circumstance it is normal practice to caveat the conclusion with the phrase, for degraded operations.

The handling qualities of the aircraft will clearly affect task performance but the skill of the pilot will also affect the outcome. To take into account the position of the test pilot Cooper and Harper expected that he would evaluate handling qualities with respect to his understanding of the lower degree of skill and training existent in a group of operational pilots. Thus the test pilot must analyze his workload in the context of a less skilled or less experienced pilot. As part of this process he or she must decide on how many attempts at the task will be undertaken before awarding an HQR. It would be unrealistic to award a rating on the first attempt but excessive practise runs can make it more difficult to analyze the compensation required. The compensation is usually most evident in the first few attempts.

HQRs are used in two main ways: either as data for control law research or as data to support conclusions in an evaluation report. An example of the latter is shown in Table 5.3. In research work a pool of pilots may be asked to attempt a task or set of tasks and the HQRs awarded can then be analyzed. This may involve averaging the numerical HQRs to determine the handling qualities level. Since, as already mentioned,

|

Table 5.3 Relationship between HQRs and other assessment criteria.

|

Cooper – Harper Task

Performance

|

HQR

|

Workload

|

HQ

Level

|

Conclusion

|

|

Desirable

|

1

|

not a factor to

minimal

|

1

|

Satisfactory

|

|

2

|

|

3

|

|

4

|

moderate

to

extensive

|

2

|

Unsatisfactory

|

|

Adequate

|

5

|

|

6

|

|

Inadequate

|

7

|

extensive

to

intense

|

3

|

Unacceptable

|

|

8

|

|

9

|

|

|

Loss of control

|

10

|

uncontrollable

|

|

the Cooper-Harper scale is not a linear measure of compensation, a certain amount of care is needed when conducting any arithmetical operations with the results. For example, an HQR 2 awarded by one pilot cannot be summed with an HQR 6 from another pilot to arrive at an HQR 4. A wide discrepancy in results like this might indicate a problem with the way the research trial had been constructed.

When using HQRs as evidence to support conclusions in evaluation reports it is vital to define the task precisely and to state the performance tolerance used. The test pilot should then use an appropriate adjective to describe the workload and should describe the amount of compensation required in terms of actual control activity and/ or mental effort. Finally the rating number is stated. The following is an example of a complete HQR statement used as supporting data for a conclusion: Maintaining heading +5 degrees during level flight at 100 KIAS was difficult requiring constant yaw pedal inputs of up to 3 cm, once per second (HQR 5). It should be remembered that the pilot should reach his conclusion on the aircraft in the role; in other words the rating awarded should not drive the conclusion. Thus the test pilot should decide on the conclusion using his or her experience of the role and then check the appropriateness of the supporting HQR. If the rating is not appropriate then the task should be repeated or the tolerances reappraised. The frequency of use of HQRs in a report is a matter of judgement. They are an extremely concise and useful means of describing and quantifying the aircraft’s handling characteristics, however their use is often restricted to avoid loss of impact and repetitiveness.

![]()

![]() V=

V=

P

P