The Taguchi-Method

Subsequently the basic ideas of the Taguchi method are summarized. For more information it is referred to [2] to [6].

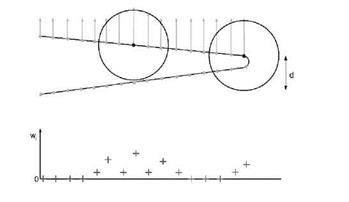

The Taguchi Method is based on the DoE-Method (Design of Experiments). DoE is a statistical method for quality management, usually used for the optimization of production cycles by determining the influence of chosen parameters on the quality of the final product. The aim of the DoE to is reduce the number of experiments needed to evaluate the influences of the parameters to a minimum in comparison to a full parameter variation. Especially the method developed by Gen’ichi Taguchi (born 1924) using orthogonal arrays for the experiment setup needs only a minimum of numbers of experiments [2]. The number of experiments required for a full parameter analysis rises exponential with the number of investigated parameters and the number of levels. If the influences of 4 parameters with 3 levels each should be investigated 34 = 81 experiments would be necessary. In the case of 13 parameters with 3 levels 2197 experiments should be done. The Taguchi method needs for these cases only 9 and 27 experiments respectively. This results in a much shorter simulation time and less required resources. Another advantage of the Taguchi-Method is the possibility to evaluate also the effects of interactions between the parameters.

In the present investigations the Taguchi method is applied to assess the impact of different parameter settings on the results of CFD simulations. These results can be the calculated lift or the different drag portions (viscous drag and pressure drag). It enables to investigate several numerical and geometrical parameters in a very short time with an acceptable number of CFD analyses.

|

A |

В |

C |

D |

||

|

1 |

1 |

1 |

1 |

1 |

R1 |

|

2 |

1 |

2 |

2 |

2 |

R2 |

|

3 |

1 |

3 |

3 |

3 |

R3 |

|

4 |

2 |

1 |

2 |

3 |

R4 |

|

5 |

2 |

2 |

3 |

1 |

R5 |

|

6 |

2 |

3 |

1 |

2 |

R6 |

|

7 |

3 |

1 |

3 |

2 |

R7 |

|

8 |

3 |

2 |

1 |

3 |

R8 |

|

9 |

3 |

3 |

2 |

1 |

R9 |

Fig. 1 L9-Taguchi-Matrix