Rudder lock occurs at a large angle of sideslip when reversed rudder aerodynamic hinge moments peg the rudder to its stop. The airplane will continue to fly sideslipped, rudder pedals free, until the pilot forces the rudder back to center or rolls out of the sideslip with the ailerons. Aerodynamic hinge moments can peg the rudder against its stops so securely as to defy the pilot’s efforts at centering. In that case recovery by rolling or pulling up to reduce airspeed are the only options.

Two things must happen before an airplane is a candidate for rudder lock. Directional stability must be low at large sideslip angles and rudder control power must be high. The relative size of the fuselage and vertical tail determines the general level of directional stability. Directional stability is reduced at large sideslip angles when the fin stalls. The sideslip angle or fin angle of attack (considering sidewash) at which the fin stalls depends on the fin aspect ratio. Unfortunately, tall, efficient, high-aspect-ratio fins stall at low fin angles of attack. As a general rule, fin stall occurs at sideslip angles of about 15 degrees.

Unlike normal wings, whose lift is proportional to angle of attack until near the stall, the lift of very low-aspect-ratio rectangular wings is proportional to the square of the angle of attack (Bollay, 1937). There is very little lift generated in the low angle of attack range. However, the angle of attack for stall is increased greatly, reaching angles as high as 45 degrees.

What this means is that a two-part vertical tail is an efficient way to avoid loss in directional stability at large sideslip angles and rudder lock. One part is a high-aspect-ratio vertical tail, which can provide directional stiffness in the normal flight regime of low sideslip angles and give good Dutch roll damping and suppression of aileron adverse yaw. The other part is a low-aspect-ratio dorsal fin, with a reasonably sharp edge, which will carry very little lifting load in the normal flight regime. However, at a sideslip angle where the high-aspect-ratio fin component stalls, the dorsal fin can become a strong lifting surface, maintaining directional stability.

Returning to the role of the rudder, large rudder areas and control power are needed for two-engine airplanes with wing-mounted engines, for the condition of single-engine failure at low airspeeds. This is especially true for propeller-powered airplanes, since full-throttle propeller thrust is highest at low airspeeds, and wing-mounted engines tend to be further outboard than for jets, to provide propeller-fuselage clearance.

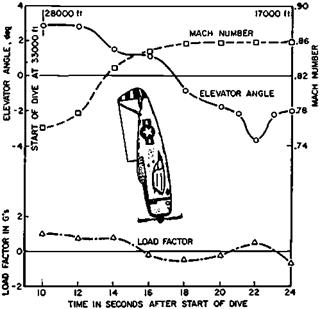

Although a four-engine rather than a two-engine airplane, rudder lock was experienced on the Boeing Model 307 Stratoliner, with its original vertical tail. This occurred during an inadvertant spin. From William H. Cook (1991):

On a demonstration flight for KLM and TWA, the KLM pilot applied rudder at low speed. The rudder locked full over in the spin, and the control forces on the rudder were too high [to center it]. Wind tunnel tests showed that a long dorsal fin would prevent the rudder locking over. A hydraulic servo on the rudder was also added.

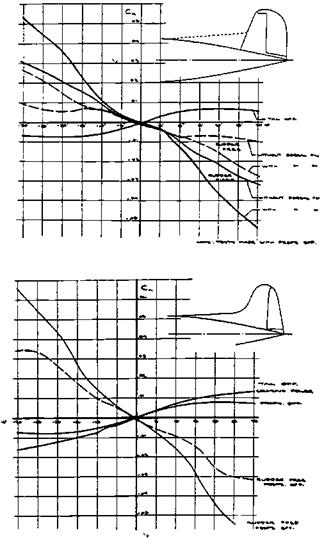

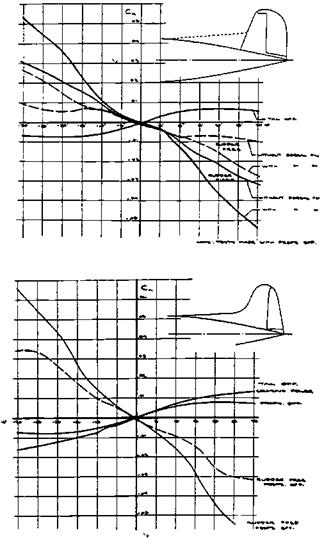

The addition of a dorsal fin to the Stratoliner and a reduction in rudder area corrected the problem (Figure 14.13) (Schairer, 1941). George Schairer recently commented that he was unaware of the true inventor of dorsal fins, but that a member of the GALCIT 10-foot tunnel staff might have installed one during tests of one of the Douglas airliners. Small dorsal fins appeared earlier than on the Stratoliner, notably on the Douglas DC-3, first produced in 1935, and on the Douglas DC-4, which had its first flight in 1938.

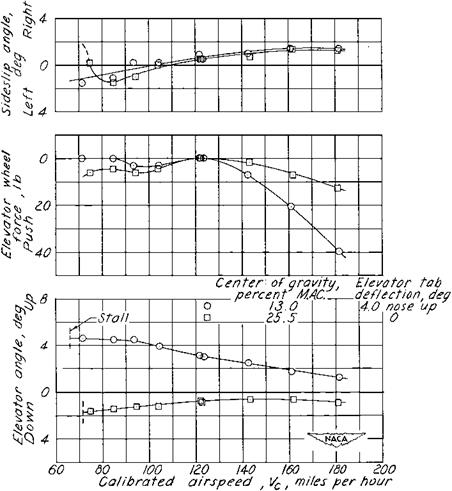

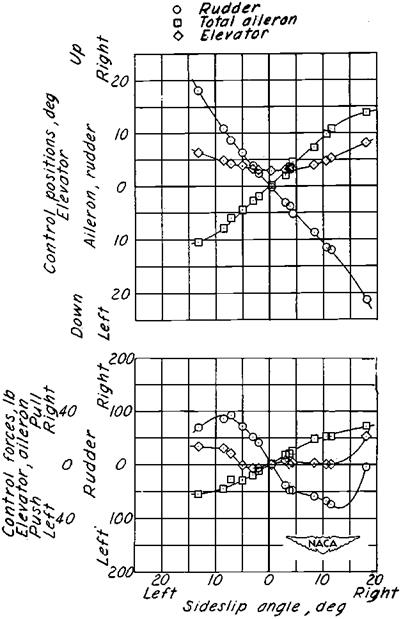

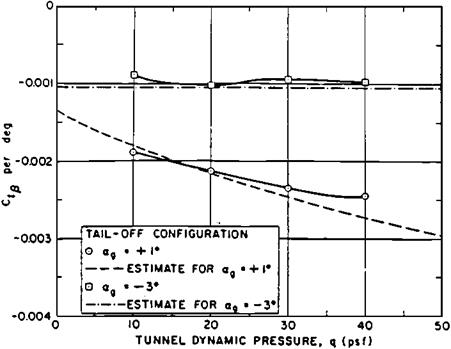

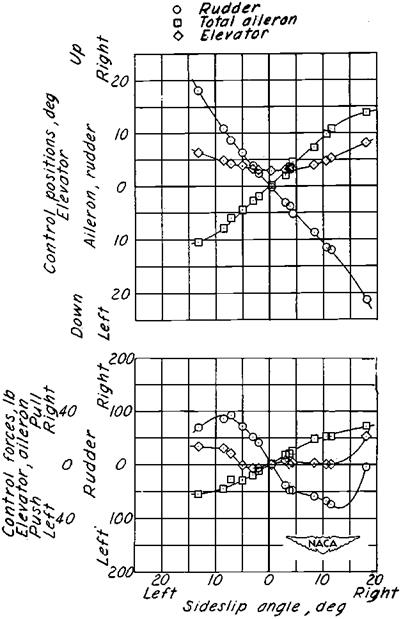

In spite of the small dorsal fin installed on the DC-3, that airplane is still subject to rudder lock in all configurations with power on (Figure 14.14). JohnA. Harper flew a U. S. Air Force C-47B, the military version of the DC-3, in NACA flying qualities tests in 1950. Harper later speculated that rudder lock might have contributed to some puzzling DC-3 accidents resulting from loss of power on one engine, followed by a stall and spin. In these strange

|

Figure 14.13 The variation of yawing moment coefficient with sideslip angle for the Boeing Stra – toliner with original vertical tail (above) and revised vertical tail and dorsal fin (below). Rudder-free cases are shown by the dashed lines. With the original tail, adverse yawing moment due to the ailerons overcomes the low level of restoring moment at large side-slip angles, and there is rudder lock. (From G. S. Schairer, Jour oftheAeo. Sci., May 1941)

|

accidents, the airplane spun into the operating engine, the reverse of what one would expect. Harper argues that rudder lock and high pedal forces for recovery could have occurred if the pilot overcontrolled with the rudder to turn toward the live engine.

Rudder lock was suspected in the early Boeing 707 airplanes, which had manually operated rudders assisted by spring tabs and internal aerodynamic balance. An Air Force test of the XC-135 tanker version reported rudder lock and an American Airlines crash on Long Island may have been due to rudder lock. As a result, the 707 and KC-135 series of airplanes have powered rudders.

|

Figure 14.14 Incipient rudder lock on the DC-3 airplane. The rudder force has gone to zero at a right sideslip angle of18 degrees. The rudderangle is only21 degrees left, with 9 more degrees of deflection available before reaching the rudder stop of 30 degrees. The rudder locks over at larger rudder and sideslip angles, but these are not reached in this test series because of heavy airplane buffet. (From Assadourian and Harper, NACA TN 3088, 1953)

|

In addition to the large rudder area requirement for the engine-out condition on multiengine airplanes, large rudder areas are needed for spin recovery on maneuverable airplanes, to handle heavy crosswinds for airplanes intended to operate out of single-strip airports, and for gliders, to counter adverse aileron yaw. Gliders have a particular adverse yaw problem because their high-aspect-ratio wings have large negative (adverse) values of yawing moment due to rolling at high lift coefficients. Pilots transitioning from light power planes to gliders, or vice versa, find vigorous rudder action in rolls is needed for coordination in gliders, as compared with light planes.

Airplanes in all of these categories might be found with dorsal fins, to prevent rudder lock. For example, the Waco CG-4A and XCG-13 cargo gliders had strong rudder lock before their vertical tails were enlarged and dorsal fins were added. On the other hand, dorsal fins have been used on airplanes as a matter of style rather than for the function of augmenting static directional stability at large angles of sideslip. This can be suspected if dorsal fins are found on airplanes that have large vertical tails at a reasonable tail length, rudders of small to moderate size, and either one or more than two engines.