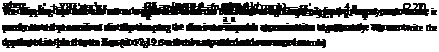

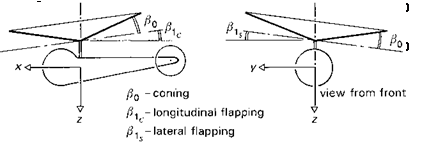

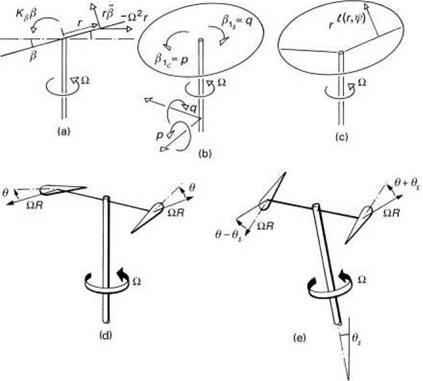

The equations of motion of a flapping rotor will be developed in a series of steps (Figs 2.18(a)-(e)), designed to highlight a number of key features of rotor behaviour. Figure 2.18(a) shows a rotating blade (Й, rad/s) free to flap (в, rad) about a hinge at the centre of rotation; to add some generality we shall add a flapping spring at the hinge (Kp, N m/rad). The flapping angle в is referred to the rotor shaft; other reference systems, e. g., relative to the control axis, are discussed in Appendix 3A. It will be shown later in Chapter 3 that this simple centre-spring representation is quite adequate for describing the flapping behaviour of teetering, articulated and hingeless or bearingless rotors, under a wide range of conditions. Initially, we consider the case of flapping in a vacuum, i. e., no aerodynamics, and we neglect the effects of gravity. The first qualitative point to grasp concerns what happens to the rotor when the rotor shaft is suddenly tilted to a new angle. For the case of the zero spring stiffness, the rotor disc

will remain aligned in its original position, there being no mechanism to generate a turning moment on the blade. With a spring added, the blade will develop a persistent oscillation about the new shaft orientation, with the inertial moment due to out-of-plane flapping and the centrifugal moment continually in balance.

The dynamic equation of flapping can be derived by taking moments about the flap hinge during accelerated motion, so that the hinge moment Kpp is balanced by the inertial moments, thus

R

Kpp = —j rm(r) [rp + rO2p} dr (2.5)

0

where m(r) is the blade mass distribution (kg/m) and (•) indicates differentiation with respect to time t. Setting О as differentiation with respect to ф = Ot, the blade azimuth angle, eqn 2.5 can be rearranged and written as

P" + Xpp = 0 (2.6)

where the flapping frequency ratio X p is given by the expression

and where the flap moment of inertia is

R

m (r ) r 2 dr

m (r ) r 2 dr

0

The two inertial terms in eqn 2.5 represent the contributions from accelerated flapping out of the plane of rotation, rp, and the in-plane centrifugal acceleration arising from the blade displacement acting towards the centre of the axis of rotation, r O2 p. Here, as will be the case throughout this book, we make the assumption that p is small, so that sin p ~ p and cos p ~ 1.

For the special case where Kp = 0, the solution to eqn 2.6 is simple harmonic motion with a natural frequency of one-per-rev, i. e., Xp = 1. If the blade is disturbed in flap, the motion will take the form of a persistent, undamped, oscillation with frequency О; the disc cut by the blade in space will take up a new tilt angle equal to the angle of the initial disturbance. Again, with Kp set to zero, there will be no tendency for the shaft to tilt in response to the flapping, since no moments can be transmitted through the flapping hinge. For the case with non-zero Kp, the frequency ratio is greater than unity and the natural frequency of disturbed motion is faster than one-per-rev, disturbed flapping taking the form of a disc precessing against the rotor rotation, if the shaft is fixed. With the shaft free to rotate, the hub moment generated by the spring will cause the shaft to rotate into the direction normal to the disc. Typically, the stiffness of a hingeless rotor blade can be represented by a spring giving an equivalent Xp of between 1.1 and 1.3. The higher values are typical of the first generation of hingeless rotor helicopters, e. g., Lynx andBo105, the lower more typical of modern bearingless designs. The overall stiffness is therefore dominated by the centrifugal force field.

Before including the effects of blade aerodynamics, we consider the case where the shaft is rotated in pitch and roll, p and q (see Fig. 2.18(b)). The blade now experiences additional gyroscopic accelerations caused by mutually perpendicular angular velocities, p, q and —. If we neglect the small effects of shaft angular accelerations, the equation of motion can be written as

„2 2

в + kpP = — (p cos ф — q sin ф) (2.9)

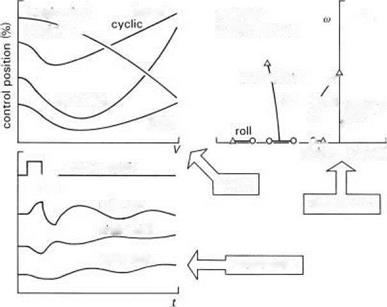

The conventional zero reference for blade azimuth is at the rear of the disc and ф is positive in the direction of rotor rotation; in eqn 2.9 the rotor is rotating anticlockwise when viewed from above. For clockwise rotors, the roll rate term would be negative. The steady-state solution to the ‘forced’ motion takes the form

в = віс cos ф + Pis sin ф (2.10)

where

These solutions represent the classic gyroscopic motions experienced when any rotating mass is rotated out of plane; the resulting motion is orthogonal to the applied rotation. в1с is a longitudinal disc tilt in response to a roll rate; P1s a lateral tilt in response to a pitch rate. The moment transmitted by the single blade to the shaft, in the rotating axes system, is simply KpP; in the non-rotating shaft axes, the moment can be written as pitch (positive nose up) and roll (positive to starboard) components

KP

M = — KpP (cos ф) = —j-(P1c(1 + cos 2ф) + P1s sin 2ф) (2.12)

Kp

L = —Kp p (sin ф) = —— (P1s (1 — cos 2ф) + P1c sin 2ф) (2.13)

Each component therefore has a steady value plus an equally large wobble at two – per-rev. For a rotor with Nb evenly spaced blades, it can be shown that the oscillatory moments cancel, leaving the steady values

|

Kp

M = – Nb – fp1c

|

(2.14)

|

|

kp

L = – Nb – fpu

|

(2.15)

|

This is a general result that will carry through to the situation when the rotor is working in air, i. e., the zeroth harmonic hub moments that displace the flight path of the aircraft are proportional to the tilt of the rotor disc. It is appropriate to highlight that we have neglected the moment of the in-plane rotor loads in forming these hub moment expressions. They are therefore strictly approximations to a more complex effect, which we shall discuss in more detail in Chapter 3. We shall see, however, that the aerodynamic loads are not only one-per-rev, but also two and higher, giving rise to vibratory moments. Before considering the effects of aerodynamics, there are two

points that need to be made about the solution given by eqn 2.11. First, what happens when Xp = 1? This is the classic case of resonance, when according to theory, the response becomes infinite; clearly, the assumption of small flap angles would break down well before this and the nonlinearity in the centrifugal stiffening with amplitude would limit the motion. The second point is that the solution given by eqn 2.11 is only part of the complete solution. Unless the initial conditions of the blade motion were very carefully set up, the response would actually be the sum of two undamped motions, one with the one-per-rev forcing frequency, and the other with the natural frequency Xв. A complex response would develop, with the combination of two close frequencies leading to a beating response or, in special cases, non-periodic ‘chaotic’ behaviour. Such situations are somewhat academic for the helicopter, as the aerodynamic forces distort the response described above in a dramatic way.

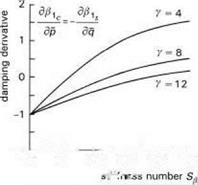

-2 ——- 1—1—- 1 1—i. I i.—і————– 1—j

-2 ——- 1—1—- 1 1—i. I i.—і————– 1—j